FANUC系统铣床与加工中心工艺编程与操作实例.docx

《FANUC系统铣床与加工中心工艺编程与操作实例.docx》由会员分享,可在线阅读,更多相关《FANUC系统铣床与加工中心工艺编程与操作实例.docx(45页珍藏版)》请在冰豆网上搜索。

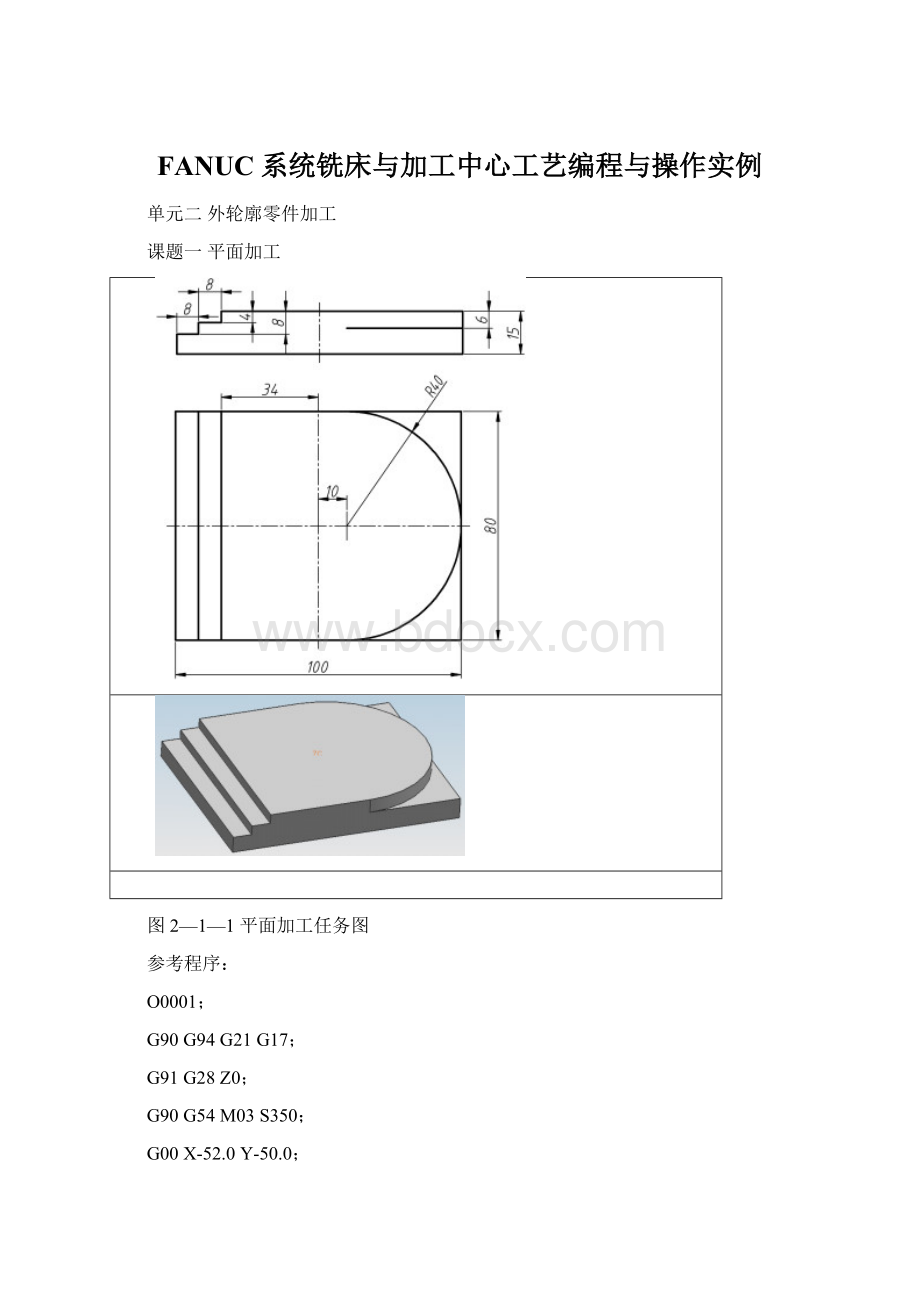

FANUC系统铣床与加工中心工艺编程与操作实例

单元二外轮廓零件加工

课题一平面加工

图2—1—1平面加工任务图

参考程序:

O0001;

G90G94G21G17;

G91G28Z0;

G90G54M03S350;

G00X-52.0Y-50.0;

Z5.0M08;

G01Z-8.0F50;

Y50.0F52;

G00Z5.0;

X-44.0Y-50.0;

G01Z-4.0F50;

Y50.0F52;

G00Z5.0;

X10.Y50.0;

G01Z-6.0F50;

G02X10.0Y-50.0R50.0F52;

G00Z20.0M09;

G91G28Z0;

M30;

课题二外形轮廓加工

图2—2—1零件加工任务图

参考程序:

(1)圆柱台加工程序

○0001;

G90G94G40G17G21;

G91G28Z0;

G90G54M3S350;

G00X62.0Y0;

Z5.0;

G01Z-4.0F52;

G41D02G01X47.0Y0F52;

G02I-47.0J0;

G40G01X62.0Y0;

G41D02G01X31.0YO;

G02I-31.0J0;

G40G01X62.0Y0;

G41D02G01X15.0Y0;

G02I-15.0J0;

G40G01X62.0Y0;

G00Z20.0;

G91G28Z0;

M30;

(2)外轮廓加工程序

○0002;

G90G94G40G17G21;

G91G28ZO;

G90G54M03S350;

G00X-62.0Y52.0M08;

Z5.0;

G01Z-9.0F52;

G41D02G01X-40.0Y30.0F52;

G01X-20.0Y30.0;

X30.0;

G02X40.0Y20.0R10.0;

G01Y-20.0;

G02X30.0Y-30.0R10.0;

G01X-30.0;

G02X-40.0Y-20.0R10.0;

G01Y10.0;

G03X-20.0Y30.0R20.0;

G40G01X-62.0Y52.0;

G00Z20.0M09;

G91G28Z0;

M30;

粗加工时,选用Φ20的立铣刀,刀具号为T02,刀具半径补偿号为D02,补偿值为10.2mm(0.2mm是精加工余量)。

精加工时,选用Φ12的立铣刀,刀具号为T03,刀具半径补偿号为D03,补偿值为6mm。

单元三内轮廓零件加工

课题一槽加工

图3—1—1槽加工任务图

参考程序:

(1)十字槽粗加工程序

○0001;

G90G40G21G17G94;

G91G28Z0;

G90G54M3S480;

G00X30.0Y0;

Z5.0M08;

G01Z-4.0F40;

X-30.0F60;

Z-8.0F40;

X30.0F60;

G00Z5.0;

X0Y25.0;

G01Z-4.0F40;

Y-25.0;

Z-8.0F40;

Y25.0F60;

G00Z5.0M09;

G91G28Z0;

M30;

(2)十字槽精加工程序

○0002;(主程序)

G90G40G21G94G17;

G91G28Z0;

G90G54M3S800;

G00X0Y0;

Z5.0M08;

G01Z0F40;

M98P0003L02;

G90G00Z5.0M09;

G91G28Z0;

M30;

○0003;(子程序)

G91G01Z-4.0F40;

G90G41D03G01X12.5Y7.5F50;

G02X7.5Y12.5R5.0;

G01Y25.0;

G03X-7.5R7.5;

G01Y12.5;

G02X-12.5Y7.5R5.0;

G01X-30.0;

G03Y-7.5R7.5;

G01X-12.5;

G02X-7.5Y-12.5R5.0;

G01Y-25.0;

G03X7.5R7.5;

G01Y-12.5;

G02X12.5Y-7.5R5.0;

G01X30.0;

G03Y7.5R7.5;

G01X12.5;

G02X7.5Y12.5R5.0;

G40G01X0Y0;

M99;

课题二型腔加工

图3—3—1型腔加工任务图

参考程序:

(1)型腔内粗加工程序

○0001;(主程序)

G90G40G21G94G17;

G91G28Z0;

G90G54M3S480;

G00X0Y0;

Z5.0M08;

G01Z0F50;

M98P0002L02;

G00Z20.0M09;

G91G28Z0;

M30;

○0002;(子程序)

G91G01Z-4.0F40;

G90G01X7.0Y0F48;

G03I-7.0J0;

G01X19.0Y0;

G03I-19.0J0;

G01X0Y0F100;

M99;

(2)型腔内轮廓精加工程序

○0003;(主程序)

G90G40G21G94G17;

G91G28Z0;

G90G54M3S480;

G00X5.0Y0;

Z5.0M08;

G01Z0F80;

M98P0004L02;

G00Z20.0M09;

G91G28Z0;

M30;

○0004;(子程序)

G91G01Z-4.0F80;

G90G41D01G01X20.0Y-15.0F48;

G03X35.0Y0R15.0;

G01Y6.7157;

G03X28.3333Y16.1438R10.0;

G02X16.1438Y28.3333R20.0;

G03X6.7157Y35.0R10.0;

G01X-6.7157;

G03X-16.1438Y28.3333R10.0;

GO2X-28.3333Y16.1438R20.0;

G03X-35.0Y6.7157R10.0;

G01Y-6.7157;

G03X-28.3333Y-16.1438R10.0;

G02X-16.1438Y-28.3333R20.0;

G03X-6.7157Y-35.0R10.0;

G01X6.7157;

G03X16.1438Y-28.3333R10.0;

G02X28.3333Y-16.1438R20.0;

G03X35.0Y-6.7157R10.0;

G01Y0;

G03X20.0Y15.0R15.0;

G40G01X5.0Y0;

M99;

单元四孔加工

课题一钻孔、攻丝加工

图4—1—1孔类零件加工任务图

参考程序:

○0001;

G91G28Z0;

M06T1;

G90G17G49G21G94;

G54M3S1200;

G00X20.0Y100.0M08;

G43H01G00Z50.0;

G99G81X-15.0Y65.0Z-4.0R5.0F80;

G98X-30.0;

G00X-120.0;

Y15.0;

G99G81X-85.0Y15.0Z-4.0R5.0F80;

G98X-70.0;

G91G28Z0M09;

M06T02;

G90G49G54M3S550;

G00X20.0Y100.0M08;

G43H02G00Z50.;

G99G73X-15.0Y65.0Z-20.0R5.0Q2.0F60;

G98X-30.0;

G00X-120.0;

Y15.0;

G99G73X-85.0Y15.0Z-20.0R5.0Q2.0F60;

G98X-70.0;

G91G28Z0M09;

M06T03;

G90G49G54M3S500;

G00X20.0Y100.0M08;

G43H03G00Z50.;

G98G83X-30.0Y65.0Z-21.0R5.0Q2.0F60;

G00X-120.0;

Y15.0;

G98G83X-70.0Y15.0Z-21.0R5.0Q2.0F60;

G91G28Z0M09;

M06T04;

G90G49G54M3S450;

G00X20.0Y100.0M08;

G43H04G00Z50.;

G98G81X-15.0Y65.0Z-21.0R5.0F50;

G00X-120.0;

Y15.0;

G98G81X-85.0Y15.0Z-21.0R5.0F50;

G91G28Z0M09;

M06T05;

G90G49G54M3S350;

G00X20.0Y100.0M08;

G43H05G00Z50.0;

G99G82X-15.0Y65.0Z-6.0R5.0P2000F60;

G98X-30.0;

G00X-120.0;

Y15.0;

G99G82X-85.0Y15.0Z-6.0R5.0P2000F60;

G98X-70.0;

G91G28Z0M09;

M06T06;

G90G49G54M3S50;

G00X20.0Y100.0M08;

G43H06G00Z50.0;

G98G85X-30.0Y65.0Z-18.0R5.0F40;

G00X-120.0;

Y15.0;

G98G85X-70.0Y15.0Z-18.0R5.0F40;

G91G28Z0M09;

M06T07;

G90G49G54M3S100;

G00X20.0Y100.0M08;

G43H07G00Z50.0;

G98G84X-15.0Y65.0Z-19.0R5.0F175;

G00X-120.0;

Y15.0;

G98G84X-85.0Y15.0Z-19.0R5.0F175;

G91G28Z0M09;

M30;

课题二镗孔加工

图4—2—1零件加工任务图

参考程序:

○0001;

G91G28Z0;

M06TO1;

G90G94G49G17G40G21;

G54M03S400;

G43H01G00Z50.0M08;

X-46.0Y55.0;

Z5.0;

G01Z-4.0F80;

Y-55.0F60;

X46.0F1000;

Y55.0F60;

G41D01G01X17.321Y30.0F60;

X34.641Y0;

X17.321Y-30.0;

X-17.321;

X-34.641Y0;

X-17.321Y30.0;

X-20.0;

G40G01X65.0Y55.0F300;

G91G28Z0M09;

M06T03;

G90G54G49G40M03S1200;

G43H03G00Z50.0M08;

G98G81X0Y0Z-4.0R5.0F60;

G91G28Z0M09;

M06T04;

G90G54G49G40M03S500;

G43H04G00Z50.0M08;

G98G81X0Y0Z-20.0R5.0F60;

G91G28Z0M09;

G28X0Y0;

M06T05;

G90G54G49G40M03S350;

G43H05G00Z50.0M08;

G98G73X0Y0Z-22.0R5.0Q2.0F50;

G91G28Z0M09;

G28X0Y0;

M06T06;

G90G54G49G40M03S250;

G43H06G00Z50.0M08;

G98G73X0Y0Z-25.0R5.0Q2.0F45;

G91G28Z0M09;

G28X0Y0;

M06T07;

G90G54G49G40M03S200;

G43H07G00Z50.0M08;

G98G73X0Y0Z-26.0R5.0Q2.0F40;

G91G28Z0M09;

M06T02;

G90G54G49G40M03S800;

G43H02G00Z50.0M08;

X46.0Y55.0;

Z5.0;

G01Z-4.0F80;

G41D02G01X17.321Y30.0F60;

X34.641Y0;

X17.321Y-30.0;

X-17.321;

X-34.641Y0;

X-17.321Y30.0;

X-20.0;

G40G01X65.0Y55.0F300;

G91G28Z0M09;

M06T08;

G90G54G49G40M03S800;

G43H08G00Z60.0M08;

G98G85X0Y0Z-17.0R5.0F60;

G91G28Z0M09;

M06T09;

G90G54G49G40M03S1500;

G43H09G00Z60.0M08;

G98G85X0Y0Z-17.0R5.0F50;

G91G28Z0M09;

G28X0Y0;

M30;

单元五综合课题加工

课题一镜像加工

图5—1—1加工任务图

参考程序:

○0001;(主程序)

G90G40G21G17G94;

G50.1X0Y0

G91G28Z0;

G90G54M3S680;

M08

M98P0002

G51.1X0

M98P0002

G50.1X0

M09

M30

○0002;(子程序)

G00X-58.0Y-48.0;

Z50.0;

Z5.0;

G01Z-3.0F50;

G41D01G01X-47.0Y-45.0F100;

X-47.0Y-20.0;

X-37.0Y-20.0;

G03X-27.0Y-10.0R10.0;

G01X-27.0Y10.0;

G03X-37.0Y20.0R10.0;

G01X-47.0Y20.0;

X-47.0Y42.5;

X-28.0Y42.5;

G02X-8.0Y22.5R20.0;

G01X-8.0Y-20.0;

X-30.5Y-42.5;

X-50.0Y-42.5;

G40G01X-58.0Y-48.0;

G00Z50.0;

M99;

课题二极坐标加工

图5—2—1加工任务图

参考程序:

○0001;

G54G40;

M08;

G15;

M03S700;

G00X58.0Y-10.0;

Z50.0;

Z5.0;

G01Z-5.0F50;

G41D01G16G01X36.0Y-5.0F100;

G02X24.0Y-5.0R6.;

G03X24.0Y275.0R-24.0;

G02X36.0Y275.0R6.0;

G02X36.0Y-5.0R-36.0;

G40G15G01X58.0Y-10.0;

G00Z150.0;

M09;

M30;

课题三旋转加工

图5—3—1加工任务图

参考程序:

○0001;

G54G40;

G69;

M03S700;

G68X0Y0R30.0;

G00X0Y0;

Z50.0M08;

Z5.0;

G01Z-5.0F50;

G41D01G01X25.0Y10.0F100;

G03X15.0Y20.0R10.0;

G01X-15.0;

G03X-25.0Y10.0R10.0;

G01Y-10.0;

G03X-15.0Y-20.0R10.0;

G01X15.0;

G03X25.0Y-10.0R10.0;

G01X25.0Y10.0;

G40G01X0Y0;

G00Z150.0M09;

M30;

课题四综合零件的加工

图5—4—1加工任务图

参考程序:

(1)正六边形加工程序

○0001;

G90G40G21G17G94;

G91G28Z0;

G90G54M03S400;

G00X0Y55.0;

Z5.0M08;

G01Z-6.F60;

G41D01G01X0Y29.0F100;

X10.97;

G02X19.63Y24.0R10.0;

G01X30.60Y5.0;

G02Y-5.0R10.0;

G01X19.63Y-24.0;

G02X10.97Y-29.0R10.0;

G01X-10.97;

G02X-19.63Y-24.0R10.0;

G01X-30.60Y-5.0;

G02Y5.0R10.0;

G01X-19.63Y24.0;

G02X-10.97Y29.0R10.0;

G01X0;

G40G01X0Y55.0;

G00Z50.0M09;

G91G28Z0;

M30;

(2)斜六边形加工主程序

○0002;(主程序)

G90G40G21G17G94G69;

G91G28Z0;

G90G68X0Y0R10.0;

M98P0003;

G69;

G91G28Z0;

M30;

○0003;(子程序)

G90G54M03S400;

G00X0Y40.0;

Z5.0M08;

G01Z-4.F60;

G41D01G01X0Y25.0F100;

X10.97;

G02X16.17Y22.0R6.0;

G01X27.14Y3.0;

G02Y-3.0R6.0;

G01X16.17Y-22.0;

G02X10.97Y-25.0R6.0;

G01X-10.97;

G02X-16.17Y-22.0R6.0;

G01X-27.14Y-3.0;

G02Y3.0R6.0;

G01X-16.17Y22.0;

G02X-10.97Y25.0R6.0;

G01X0;

G40G01X0Y40.0;

G00Z50.0M09;

M99;

(3)凹槽加工程序

○0004;(主程序)

G90G40G21G17G94;

G54M03S680;

GO0X60Y-50;

Z5.0M08;

M98P0005;

G51.1X0Y0;

M98P0005;

G50.1X0Y0;

G0Z100.0M09;

M30

○0005;(子程序)

G00X56.0Y-46.0;

G01Z-8.0F50;

G41D04G01X52.34Y-33.55F;

X34.88Y-19.58;

G3X26.76Y-29.73R6.5;

G1X41.94Y-41.87;

G40G01X56.0Y-46.0;

G00Z5.0;

M99;

(4)孔加工程序

○0006;

G91G28Z0;

M06T05;

G90G40G21G17G94G15;

G54M03S1500;

GO0X0Y0;

G43H05G00Z20.0;

G16G00X40.0Y40.0;

G99G81Z-9.0R5.0F60;

G00X40.0Y210.0;

G98G81Z-9.0R5.0F60;

G15;

G91G28Z0;

M06T06;

G90G15G54M3S500;

GO0X0Y0;

G43H06G00Z20.0;

G16G00X40.0Y40.0;

G99G81Z-20.0R5.0F60;

G00X40.0Y210.0;

G98G81Z-20.0R5.0F60;

G15;

G91G28Z0;

M06T07;

G90G15G54M03S450;

GO0X0Y0;

G43H07G00Z20.0;

G16G00X40.0Y40.0;

G99G81Z-20.0R5.0F50;

G00X40.0Y210.0;

G98G81Z-20.0R5.0F50;

G15;

G91G28Z0;

M06T08;

G90G15G54M03S500;

GO0X0Y0;

G43H08G00Z20;

G16G00X40.0Y40.0;

G99G82Z-10.0R5.0P2000F60;

G00X40.0Y210.0;

G99G82Z-10.0R5.0P2000F60;

G15;

G91G28Z0;

M06T09;

G90G15G54M03S50;

GO0X0Y0;

G43H09G00Z20.0;

G16G00X40.0Y40.0;

G99G85Z-18.0R5.0F40;

G00X40.0Y210.0

G98G85Z-18.0R5.0F40;

G15;

G91G28Z0;

M30;

数控编程实例

1.根据图样要求、毛坯及前道工序加工情况,确定工艺方案及加工路线

1)以已加工过的底面为定位基准,用通用台虎钳夹紧工件前后两侧面,台虎钳固定于铣床工作台上。

2)工步顺序

①铣刀先走两个圆轨迹,再用左刀具半径补偿加工50㎜×50㎜四角倒圆的正方形。

②每次切深为2㎜,分二次加工完。

2.选择机床设备

根据零件图样要求,选用经济型数控铣床即可达到要求。

故选用XKN7125型数控立式铣床。

3.选择刀具

现采用φ10㎜的平底立铣刀,定义为T01,并把该刀具的直径输入刀具参数表中。

4.确定切削用量

切削用量的具体数值应根据该机床性能、相关的手册并结合实际经验确定,详见加工程序。

5.确定工件坐标系和对刀点

在XOY平面内确定以工件中心为工件原点,Z方向以工