大学方案外文翻译冲压模具方案成型方面.docx

《大学方案外文翻译冲压模具方案成型方面.docx》由会员分享,可在线阅读,更多相关《大学方案外文翻译冲压模具方案成型方面.docx(15页珍藏版)》请在冰豆网上搜索。

大学方案外文翻译冲压模具方案成型方面

英文翻译

4Sheetmetalformingandblanking

4.1Principlesofdiemanufacture

4.1.1Classificationofdies

Inmetalforming,thegeometryoftheworkpieceisestablishedentirelyorpartiallybythegeometryofthedie.Incontrasttomachiningprocesses,ignificantlygreaterforcesarenecessaryinforming.Duetothecomplexityoftheparts,formingisoftennotcarriedoutinasingleoperation.Dependingonthegeometryofthepart,productioniscarriedoutinseveraloperationalstepsviaoneorseveralproductionprocessessuchasformingorblanking.Oneoperationcanalsoincludeseveralprocessessimultaneously(cf.Sect.2.1.4>.

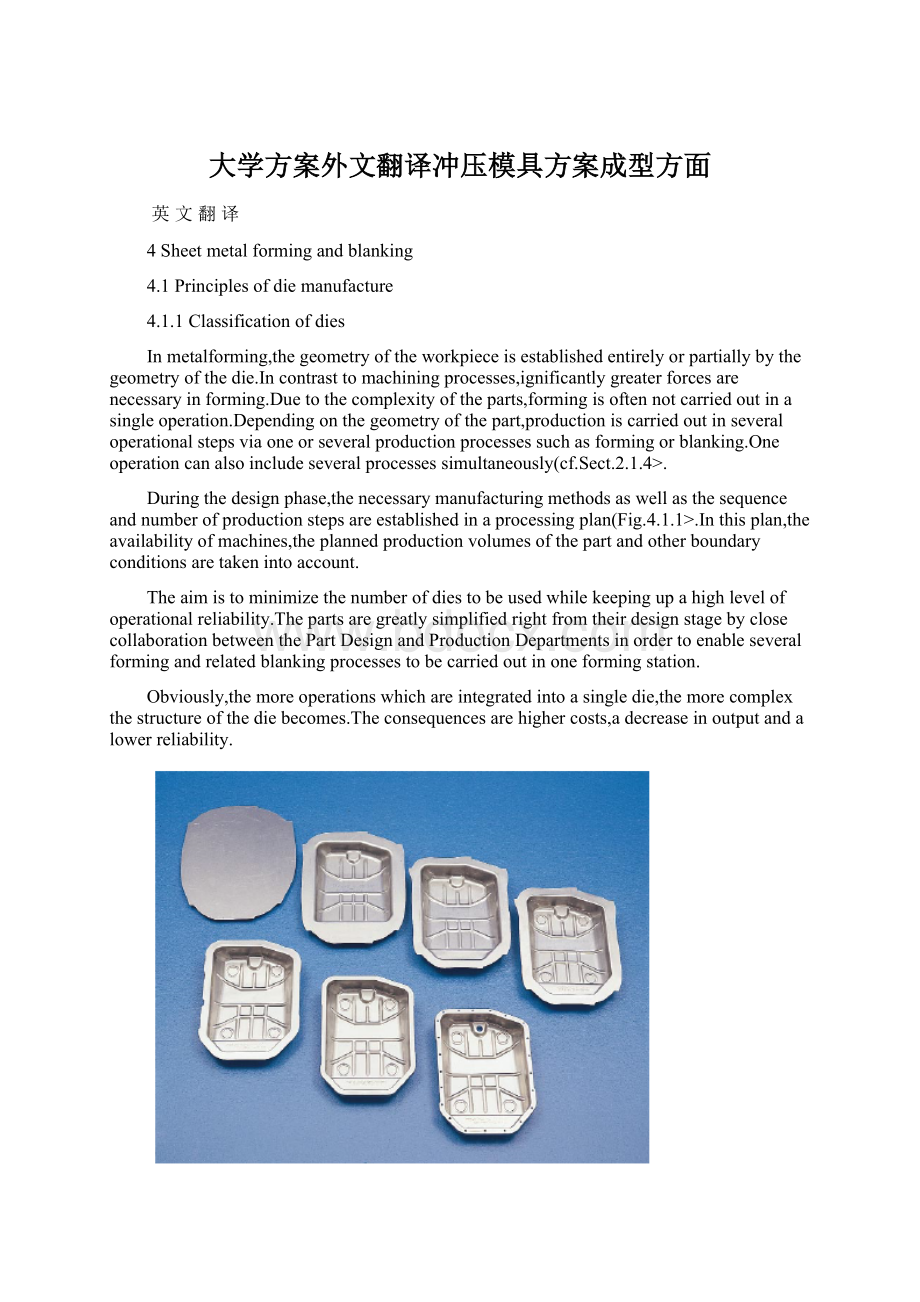

Duringthedesignphase,thenecessarymanufacturingmethodsaswellasthesequenceandnumberofproductionstepsareestablishedinaprocessingplan(Fig.4.1.1>.Inthisplan,theavailabilityofmachines,theplannedproductionvolumesofthepartandotherboundaryconditionsaretakenintoaccount.

Theaimistominimizethenumberofdiestobeusedwhilekeepingupahighlevelofoperationalreliability.ThepartsaregreatlysimplifiedrightfromtheirdesignstagebyclosecollaborationbetweenthePartDesignandProductionDepartmentsinordertoenableseveralformingandrelatedblankingprocessestobecarriedoutinoneformingstation.

Obviously,themoreoperationswhichareintegratedintoasingledie,themorecomplexthestructureofthediebecomes.Theconsequencesarehighercosts,adecreaseinoutputandalowerreliability.

Fig.4.1.1Productionstepsforthemanufactureofanoilsump

Typesofdies

Thetypeofdieandthecloselyrelatedtransportationofthepartbetweendiesisdeterminedinaccordancewiththeformingprocedure,thesizeofthepartinquestionandtheproductionvolumeofpartstobeproduced.

Theproductionoflargesheetmetalpartsiscarriedoutalmostexclusivelyusingsinglesetsofdies.Typicalpartscanbefoundinautomotivemanufacture,thedomesticapplianceindustryandradiatorproduction.Suitabletransfersystems,forexamplevacuumsuctionsystems,allowtheinstallationofdouble-actiondiesinasufficientlylargemountingarea.Inthisway,forexample,therightandleftdoorsofacarcanbeformedjointlyinoneworkingstroke(cf.Fig.4.4.34>.

Largesizesinglediesareinstalledinlargepresses.Thetransportationofthepartsfromoneformingstationtoanotheriscarriedoutmechanically.Inapresslinewithsinglepressesinstalledonebehindtheother,feedersorrobotscanbeused(cf.Fig.4.4.20to4.4.22>,whilstinlarge-paneltransferpresses,systemsequippedwithgripperrails(cf.Fig.4.4.29>orcrossbarsuctionsystems(cf.Fig.4.4.34>areusedtotransfertheparts.

Transferdiesareusedfortheproductionofhighvolumesofsmallerandmediumsizeparts(Fig.4.1.2>.Theyconsistofseveralsingledies,whicharemountedonacommonbaseplate.Thesheetmetalisfedthroughmostlyinblankformandalsotransportedindividuallyfromdietodie.Ifthisparttransportationisautomated,thepressiscalledatransferpress.Thelargesttransferdiesareusedtogetherwithsinglediesinlarge-paneltransferpresses(cf.Fig.4.4.32>.

Inprogressivedies,alsoknownasprogressiveblankingdies,sheetmetalpartsareblankedinseveralstages。

generallyspeakingnoactualformingoperationtakesplace.Thesheetmetalisfedfromacoilorintheformofmetalstrips.Usinganappropriatearrangementoftheblankswithintheavailablewidthofthesheetmetal,anoptimalmaterialusageisensured(cf.Fig.4.5.2to4.5.5>.Theworkpieceremainsfixedtothestripskeletonupuntilthela

Fig.4.1.2Transferdiesetfortheproductionofanautomatictransmissionforanautomotiveapplication

-stoperation.Thepartsaretransferredwhentheentirestripisshiftedfurtherintheworkflowdirectionaftertheblankingoperation.Thelengthoftheshiftisequaltothecenterlinespacingofthediesanditisalsocalledthestepwidth.Sideshears,veryprecisefeedingdevicesorpilotpinsensurefeed-relatedpartaccuracy.Inthefinalproductionoperation,thefinishedpart,i.e.thelastpartinthesequence,isdisconnectedfromtheskeleton.Afieldofapplicationforprogressiveblankingtoolsis,forexample,intheproductionofmetalrotorsorstatorblanksforelectricmotors(cf.Fig.4.6.11and4.6.20>.

Inprogressivecompounddiessmallerformedpartsareproducedinseveralsequentialoperations.Incontrasttoprogressivedies,notonlyblankingbutalsoformingoperationsareperformed.However,theworkpiecealsoremainsintheskeletonuptothelastoperation(Fig.4.1.3andcf.Fig.4.7.2>.Duetotheheightoftheparts,themetalstripmustberaisedup,generallyusingliftingedgesorsimilarliftingdevicesinordertoallowthestripmetaltobetransportedmechanically.Pressedmetalpartswhichcannotbeproducedwithinametalstripbecauseoftheirgeometricaldimensionsarealternativelyproducedontransfersets.

Fig.4.1.3Reinforcingpartofacarproducedinastripbyacompounddieset

Nexttothediesalreadymentioned,aseriesofspecialdiesareavailableforspecialindividualapplications.Thesediesare,asarule,usedseparately.Specialoperationsmakeitpossible,however,forspecialdiestobeintegratedintoanoperationalSequence.Thus,forexample,inflangingdiesseveralmetalpartscanbejoinedtogetherpositivelythroughthebendingofcertainmetalsections(Fig.4.1.4andcf.Fig.2.1.34>.Duringthisoperationreinforcingparts,glueorothercomponentscanbeintroduced.

Otherspecialdieslocatespecialconnectingelementsdirectlyintothepress.Sortingandpositioningelements,forexample,bringstampingnutssynchronisedwiththepresscyclesintothecorrectpositionsothatthepunchheadscanjointhemwiththesheetmetalpart(Fig.4.1.5>.Ifthereissufficientspaceavailable,formingandblankingoperationscanbecarriedoutonthesamedie.

Furtherexamplesincludebending,collar-forming,stamping,fineblanking,wobbleblankingandweldingoperations(cf.Fig.4.7.14and4.7.15>.

Fig.4.1.4Ahemmingdie

Fig.4.1.5Apressedpartwithanintegratedpunchednut

4.1.2Diedevelopment

Traditionallythebusinessofdieengineeringhasbeeninfluencedbytheautomotiveindustry.Thefollowingobservationsaboutthediedevelopmentaremostlyrelatedtobodypaneldieconstruction.Essentialstatementsare,however,madeinafundamentalcontext,sothattheyareapplicabletoallareasinvolvedwiththeproductionofsheet-metalformingandblankingdies.

Timingcycleforamassproducedcarbodypanel

Untiltheendofthe1980ssomecarmodelswerestillbeingproducedforsixtoeightyearsmoreorlessunchangedorinslightlymodifiedform.Today,however,productiontimecyclesaresetforonlyfiveyearsorless(Fig.4.1.6>.Followingthenewdifferentmodelpolicy,thedemandsondiemakershavealsochangedfundamentally.ComprehensivecontractsofmuchgreaterscopesuchasSimultaneousEngineering(SE>contractsarebecomingincreasinglycommon.Asaresult,thediemakerisofteninvolvedattheinitialdevelopmentphaseofthemetalpartaswellasintheplanningphasefortheproductionprocess.Therefore,amuchbroaderinvolvementisestablishedwellbeforetheactualdiedevelopmentisinitiated.

Fig.4.1.6Timescheduleforamassproducedcarbodypanel

ThetimetableofanSEproject

Withinthecontextoftheproductionprocessforcarbodypanels,onlyaminimalamountoftimeisallocatedtoallowforthemanufactureofthedies.Withlargescalediesthereisarun-upperiodofabout10monthsinwhichdesignanddietry-outareincluded.IncomplexSEprojects,whichhavetobecompletedin1.5to2years,paralleltasksmustbecarriedout.Furthermore,additionalresourcesmustbeprovidedbeforeandafterdeliveryofthedies.Theseshortperiodscallforpre-ciseplanning,specificknow-how,availablecapacityandtheuseofthelatesttechnologicalandcommunicationssystems.Thetimetableshowstheindividualactivitiesduringthemanufacturingofthediesfortheproductionofthesheetmetalparts(Fig.4.1.7>.Thetimephasesforlargescalediesaremoreorlesssimilarsothatthistimetablecanbeconsideredtobevalidingeneral.

Datarecordandpartdrawing

Thedatarecordandthepartdrawingserveasthebasisforallsubsequentprocessingsteps.Theydescribeallthedetailsofthepartstobeproduced.Theinformationgiveninthe

Fig.4.1.7TimetableforanSEproject

partdrawingincludes:

partidentification,partnumbering,sheetmetalthickness,sheetmetalquality,tolerancesofthefinishedpartetc.(cf.Fig.4.7.17>.

Toavoidtheproductionofphysicalmodels(masterpatterns>,theCADdatashoulddescribethegeometryofthepartcompletelybymeansofline,surfaceorvolumemodels.Asageneralrule,highqualitysurfacedatawithacompletelyfilletedandclosedsurfacegeometrymustbemadeavailabletoalltheparticipantsinaprojectasearlyaspossible.

Processplananddrawdevelopment

Theprocessplan,whichmeanstheoperationalsequencetobefollowedintheproductionofthesheetmetalcomponent,isdevelopedfromthedatarecordofthefinishedpart(cf.Fig.4.1.1>.Alreadyatthispointintime,variousboundaryconditionsmustbetakenintoaccount:

thesheetmetalmaterial,thepresstobeused,transferofthepartsintothepress,thetransportationofscrapmaterials,theundercutsaswellasthe

slidingpininstallationsandtheiradjustment.

Thedrawdevelopment,i.e.thecomputeraideddesignandlayoutoftheblankholderareaofthepartinthefirstformingstage–ifneedbealsothesecondstage–,requiresaprocessplannerwithconsiderableexperience(Fig.4.1.8>.Inordertorecognizeandavoidproblemsinareaswhicharedifficulttodraw,itisnecessarytomanufactureaphysicalanalysismodelofthedrawdevelopment.Withthismodel,