ISO验厂文件清单.docx

《ISO验厂文件清单.docx》由会员分享,可在线阅读,更多相关《ISO验厂文件清单.docx(56页珍藏版)》请在冰豆网上搜索。

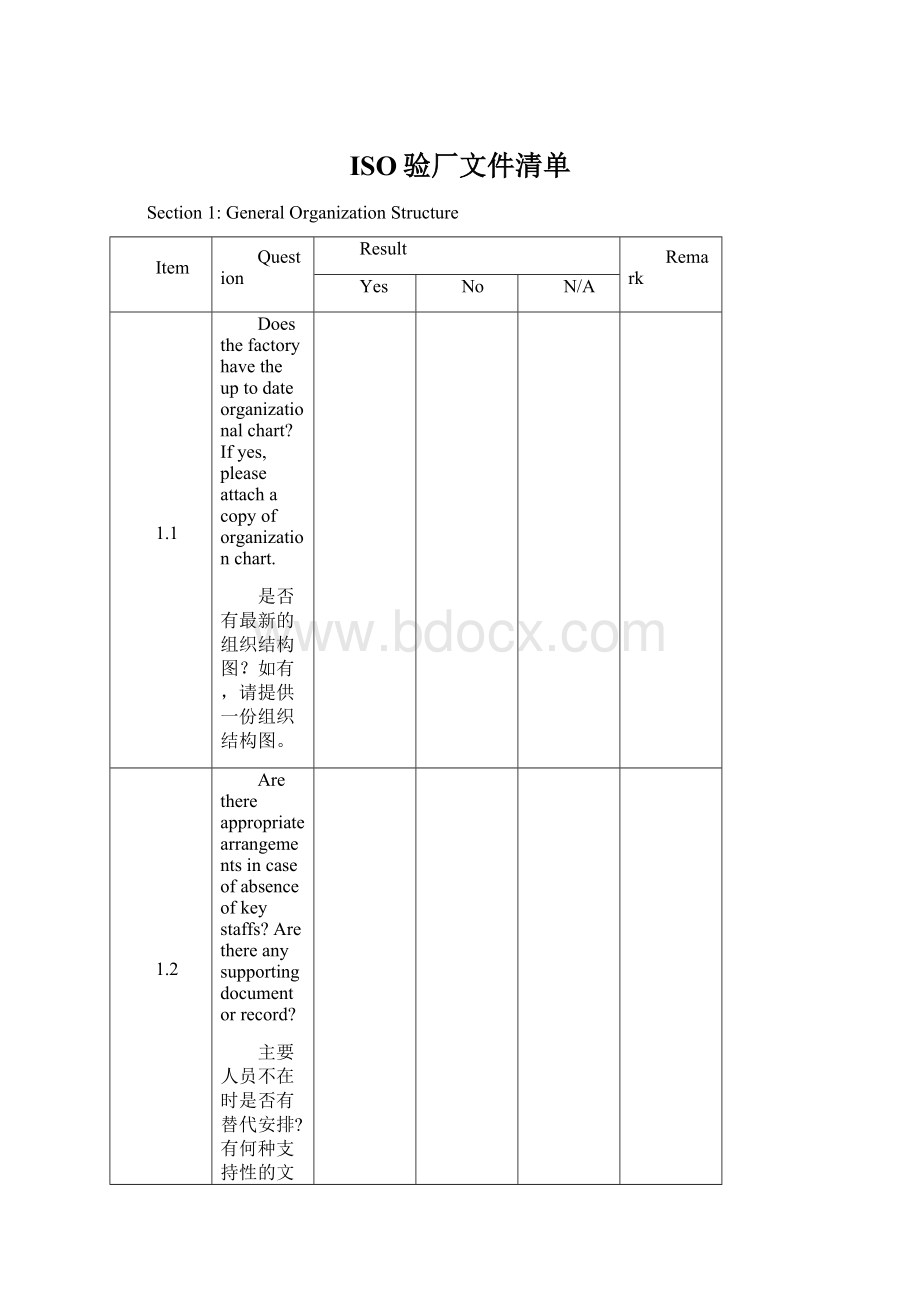

ISO验厂文件清单

Section1:

GeneralOrganizationStructure

Item

Question

Result

Remark

Yes

No

N/A

1.1

Doesthefactoryhavetheuptodateorganizationalchart?

Ifyes,pleaseattachacopyoforganizationchart.

是否有最新的组织结构图?

如有,请提供一份组织结构图。

1.2

Arethereappropriatearrangementsincaseofabsenceofkeystaffs?

Arethereanysupportingdocumentorrecord?

主要人员不在时是否有替代安排?

有何种支持性的文件或记录?

1.3

Doesthefactoryhavethedefinitionofresponsibility&accountabilityforkeystaffsinvolvedwithactivitiesimpactingproductsafety,legalityandquality?

对于负责产品安全性、合法性和质量的主要人员,是否有规定的职责和权限?

Section2:

GeneralFacilityManagement

Item

Question

Result

Remark

Yes

No

N/A

2.1

Isthefactorysitebeingmaintainedtominimizepotentialforproductcontaminationanddamage?

厂房是否维护良好,避免产品被污染或损害?

2.2

Doesthefactoryfreeofanyprocessrunningoutside/outdoorsoronlywithasunshade?

是否没有工序或操作在室外或只在有顶棚的外部区域进行?

2.3

Doesthefactoryhavetheprocessflowdiagram?

Ifyes,pleaseattachacopyofflowdiagram.

是否有工序流程图?

如是,请提供流程图复印件。

2.4

Doesthefactorysiteallowsufficientworkingspaceandstoragecapacitytoenablealloperationstobeconductedundersafeandnecessaryhygienicconditions?

是否有足够的作业及储存空间,使生产处于安全和卫生的条件下进行?

2.5

Doesthefactoryeffectivelysegregaterawmaterial,workinprogress,rework,packagingandfinishedproductstominimizetheriskofcross-contamination?

是否对原材料、半成品、返工产品、包装材料及成品等进行有效隔离,防止交叉污染?

2.6

Areallmachineandequipmentadequatelymaintainedandoperatedtoproductsafety,qualityandlegality?

Aretheremaintenanceplanandrecordsavailable?

所有的设备是否维护良好,以满足产品安全,合法性及质量的要求?

是否有设备保养计划和记录?

2.7

Arecleaningandpestcontrolchemicalssuitablyidentified,labelled,controlledandadequatelystoredtopreventriskofproductsafety,qualityandlegality?

用于清洁和灭虫的化学品是否适当标识,控制和储存,以免影响到产品的安全,质量和合法性?

2.8

Aredocumentedcleaningproceduresavailable(bothin-houseandoutsourced)andmaintainedforthefactorysite,utilities,plantsandallequipment?

Followinginformationshouldbeincluded

responsiblepersonforcleaning

item/areatobecleaned

frequencyofcleaning

methodofcleaning

cleaningmaterialstobeused

cleaningrecordsandresponsiblepersonforverification

revalidationprocedure

对于厂区(内外部),公共设施及设备是否有书面的清洁程序,内容包括:

负责人;清洁区域,范围;清洁频次;清洁方式;使用的清洁工具;清洁记录和验证人;消毒和清洁程序的再确认。

2.9

Arecleaning,sanitationandhousekeepingcarriedoutbytrainedpersonnelinaccordancewithprocedures,effectiveness,correctiveactionsverifiedanddocumentedandrecordsmaintained?

清洁消毒等是否由经过培训的人员实施,是否有相应的清洁记录和必要的验证及纠正措施记录?

2.10

Isthereanylicenseorregistryrequiredfromtheappropriategovernmentagency?

Ifyes,pleaseattachacopyoflicenseorregistry.

是否有获得适当政府机构所发出的营业执照?

如是,请提供营业执照的复印件。

Section3:

QualityManagementSystems

Item

Question

Result

Remark

Yes

No

N/A

3.1

IsthisanISO9000accreditedfactory?

Ifso,pleaseattachacopyofcertification.

是否获得ISO9000质量体系认证?

如是,请提供质量体系认证证书复印件。

3.2

Doesthequalitymanagementsystemincludequalitypolicy,measurablequalityobjectives,qualitymanual,productsafety,procedureandworkinstructionsandreviewedatleastannually?

质量管理体系是否包括质量方针,可测量的质量目标,质量手册,产品安全性,程序文件,作业指导书及年度评审?

3.3

Isthereanadequatesystemforcontrollingcustomerrequirement?

是否有足够的系统来控制顾客的要求?

3.4

Doesthefactoryestablishspecificationsforrawmaterials,components,andbought-inpartsincludingpackaging,intermediate/semi-processedandanyproductorservicewhichcouldimpacttheintegrityofthefinishproduct?

对于所有影响最终产品的原材料,零部件,包材,半成品等,是否建立相关的规格要求?

3.5

Doesthefactoryhaveclearlyproductspecifications?

是否有成品规范?

*3.6

Arespecificationsaccurateandcomplyingtorelevantsafety,legislativeandcustomerrequirements?

规范是否正确并符合相关安全标准、法规及顾客要求?

3.7

Isthereanup-to-datesuppliers&sub-contractorslistandsuppliers/sub-contractorcontrolprocedureavailable?

是否有最新的合格供方(供应商,分包商)清单,及供应商/分包商的控制程序?

3.8

Arethereinternalauditprocedureandrecordsavailable?

是否有内审程序和记录?

3.9

Doesthefactoryhavedocumentcontrolprocedure?

是否有文件控制程序?

3.10

Doesthefactoryhaverecordcontrolprocedure?

是否有记录控制程序?

3.11

Doesthefactorydocumentallprocessandproductchanges?

过程和产品的变更,是否都保留记录?

3.12

DoesthefactoryhaveCAPAprocedure?

是否有纠正预防措施程序?

3.13

Arethemanagementreviewconductedatleastannually,documentedandincludetheevaluationofbelow?

Internal,customerandexternalaudits

Previousmanagementreviewdocuments,correctiveactionplansandtimeframes

Customerperformanceindicators,complaintsandfeedback

Incidents,nonconformingmaterialsandcorrectiveactions

Anassessmentofprocessperformance

Rev