VerificationExample.docx

《VerificationExample.docx》由会员分享,可在线阅读,更多相关《VerificationExample.docx(11页珍藏版)》请在冰豆网上搜索。

VerificationExample

|VerificationExample||Preprocessing||Solution||Postprocessing||CommandLine|

|BicycleExample||Preprocessing||Solution||Postprocessing||CommandLine|

Introduction

ThistutorialwascreatedusingANSYS7.0tosolveasimple3Dspaceframeproblem.

ProblemDescription

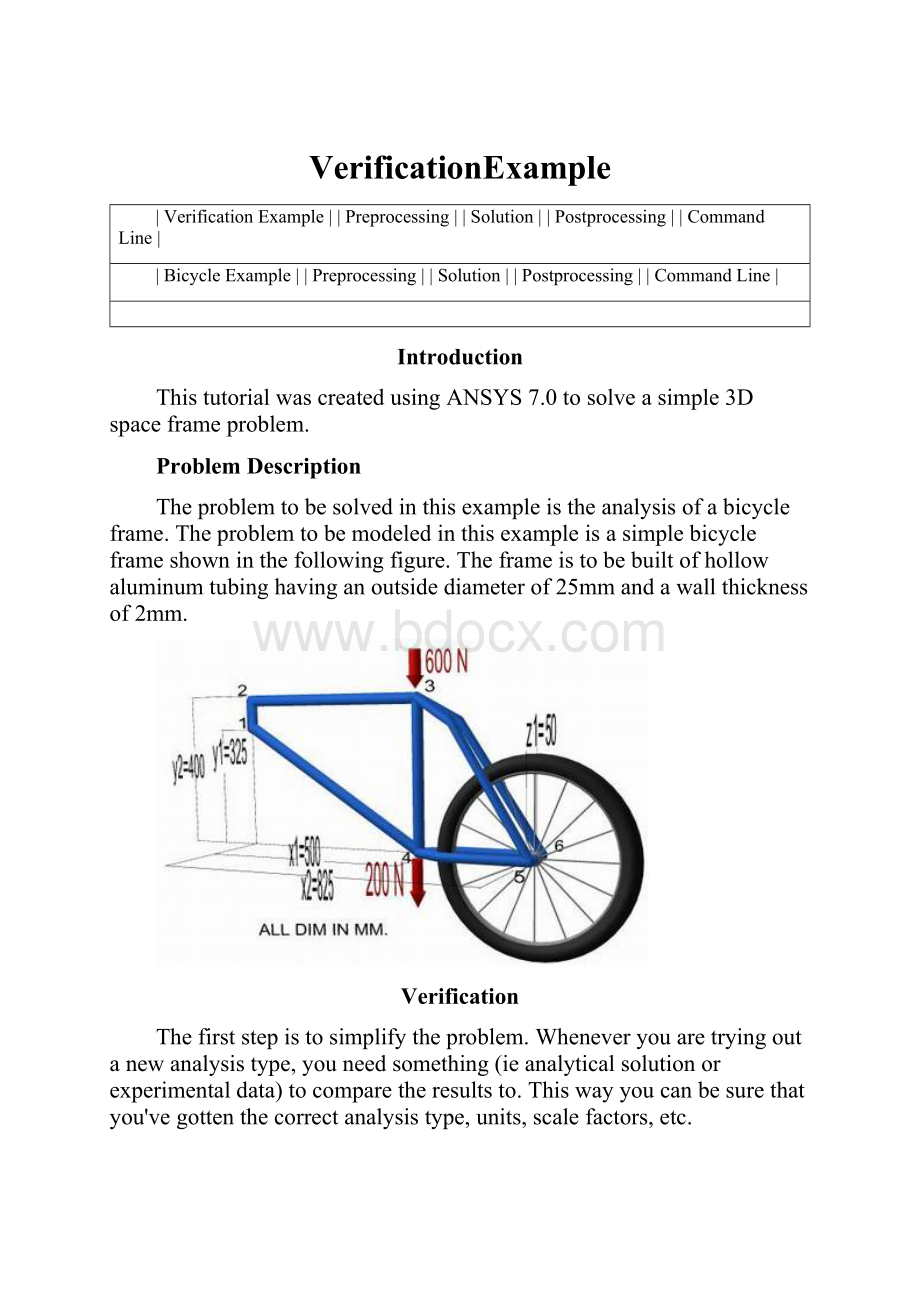

Theproblemtobesolvedinthisexampleistheanalysisofabicycleframe.Theproblemtobemodeledinthisexampleisasimplebicycleframeshowninthefollowingfigure.Theframeistobebuiltofhollowaluminumtubinghavinganoutsidediameterof25mmandawallthicknessof2mm.

Verification

Thefirststepistosimplifytheproblem.Wheneveryouaretryingoutanewanalysistype,youneedsomething(ieanalyticalsolutionorexperimentaldata)tocomparetheresultsto.Thiswayyoucanbesurethatyou'vegottenthecorrectanalysistype,units,scalefactors,etc.

Thesimplifiedversionthatwillbeusedforthisproblemisthatofacantileverbeamshowninthefollowingfigure:

Preprocessing:

DefiningtheProblem

1.GivetheSimplifiedVersionaTitle(suchas'VerificationModel').

UtilityMenu>File>ChangeTitle

2.EnterKeypoints

Forthissimpleexample,thesekeypointsaretheendsofthebeam.

oWearegoingtodefine2keypointsforthesimplifiedstructureasgiveninthefollowingtable

keypoint

coordinate

x

y

z

1

0

0

0

2

500

0

0

oFromthe'ANSYSMainMenu'select:

Preprocessor>Modeling>Create>Keypoints>InActiveCS

3.FormLines

Thetwokeypointsmustnowbeconnectedtoformabarusingastraightline.

oSelect:

Preprocessor>Modeling>Create>Lines>Lines>StraightLine.

oPickkeypoint#1(i.e.clickonit).Itwillnowbemarkedbyasmallyellowbox.

oNowpickkeypoint#2.Apermanentlinewillappear.

oWhenyou'redone,clickon'OK'inthe'CreateStraightLine'window.

4.DefinetheTypeofElement

Itisnownecessarytocreateelementsonthisline.

oFromthePreprocessorMenu,select:

ElementType>Add/Edit/Delete.

oClickonthe'Add...'button.Thefollowingwindowwillappear:

oForthisexample,wewillusethe3Delasticstraightpipeelementasselectedintheabovefigure.Selecttheelementshownandclick'OK'.Youshouldsee'Type1PIPE16'inthe'ElementTypes'window.

oClickonthe'Options...'buttoninthe'ElementTypes'dialogbox.Thefollowingwindowwillappear:

oClickandholdtheK6button(secondfromthebottom),andselect'IncludeOutput'andclick'OK'.Thisgivesusextraforceandmomentoutput.

oClickon'Close'inthe'ElementTypes'dialogboxandclosethe'ElementType'menu.

5.DefineGeometricProperties

Wenowneedtospecifygeometricpropertiesforourelements:

oInthePreprocessormenu,selectRealConstants>Add/Edit/Delete

oClickAdd...andselect'Type1PIPE16'(actuallyitisalreadyselected).Clickon'OK'.

oEnterthefollowinggeometricproperties:

oOutsidediameterOD:

25

oWallthicknessTKWALL:

2

Thisdefinesanoutsidepipediameterof25mmandawallthicknessof2mm.

oClickon'OK'.

o'Set1'nowappearsinthedialogbox.Clickon'Close'inthe'RealConstants'window.

6.ElementMaterialProperties

Youthenneedtospecifymaterialproperties:

oInthe'Preprocessor'menuselectMaterialProps>MaterialModels...

oDoubleclickStructural>Linear>Elasticandselect'Isotropic'(doubleclickonit)

oClosethe'DefineMaterialModelBehavior'Window.

WearegoingtogivethepropertiesofAluminum.Enterthefollowingfield:

EX70000

PRXY0.33

oSetthesepropertiesandclickon'OK'.

7.MeshSize

oInthePreprocessormenuselectMeshing>SizeCntrls>ManualSize>Lines>AllLines

oInthesize'SIZE'field,enterthedesiredelementlength.Forthisexamplewewantanelementlengthof2cm,therefore,enter'20'(i.e20mm)andthenclick'OK'.Notethatwehavenotyetmeshedthegeometry,wehavesimplydefinedtheelementsizes.

(Alternatively,wecouldenterthenumberofdivisionswewantintheline.Foranelementlengthof2cm,wewouldenter25[ie25divisions]).

8.NOTE

Itisnotnecessarytomeshbeamelementstoobtainthecorrectsolution.However,meshingisdoneinthiscasesothatwecanobtainresults(iestress,displacement)atintermediatepositionsonthebeam.

9.Mesh

Nowtheframecanbemeshed.

oInthe'Preprocessor'menuselectMeshing>Mesh>Linesandclick'PickAll'inthe'MeshLines'Window

10.SavingYourWork

UtilityMenu>File>Saveas....Selectthenameandlocationwhereyouwanttosaveyourfile.

SolutionPhase:

AssigningLoadsandSolving

1.DefineAnalysisType

oFromtheSolutionMenu,select'AnalysisType>NewAnalysis'.

oEnsurethat'Static'isselectedandclick'OK'.

2.ApplyConstraints

oIntheSolutionmenu,selectDefineLoads>Apply>Structural>Displacement>OnKeypoints

oSelecttheleftendoftherod(Keypoint1)byclickingonitintheGraphicsWindowandclickon'OK'inthe'ApplyU,ROTonKPs'window.

oThislocationisfixedwhichmeansthatalltranslationalandrotationaldegreesoffreedom(DOFs)areconstrained.Therefore,select'AllDOF'byclickingonitandenter'0'intheValuefieldandclick'OK'.

3.ApplyLoads

Asshowninthediagram,thereisaverticallydownwardloadof100Nattheendofthebar

oIntheStructuralmenu,selectForce/Moment>onKeypoints.

oSelectthesecondKeypoint(rightendofbar)andclick'OK'inthe'ApplyF/M'window.

oClickonthe'Directionofforce/mom'atthetopandselectFY.

oEnteravalueof-100inthe'Force/momentvalue'boxandclick'OK'.

oTheforcewillappearinthegraphicswindowasaredarrow.

Theappliedloadsandconstraintsshouldnowappearasshownbelow.

4.SolvingtheSystem

WenowtellANSYStofindthesolution:

oSolution>Solve>CurrentLS

Postprocessing:

ViewingtheResults

1.HandCalculations

Now,sincethepurposeofthisexercisewastoverifytheresults-weneedtocalculatewhatweshouldfind.

Deflection:

Themaximumdeflectionoccursattheendoftherodandwasfoundtobe6.2mmasshownabove.

Stress:

Themaximumstressoccursatthebaseoftherodandwasfoundtobe64.9MPaasshownabove(purebendingstress).

2.ResultsUsingANSYS

Deformation

ofromtheMainMenuselectGeneralPostprocfromthe'ANSYSMainMenu'.Inthismenuyouwillfindavarietyofoptions,thetwowhichwewilldealwithnoware'PlotResults'and'ListResults'

oSelectPlotResults>DeformedShape.

oSelect'Def+undefedge'andclick'OK'toviewboththedeformedandtheundeformedobject.

oObservethevalueofthemaximumdeflectionintheupperlefthandcorner(shownheresurroundedbyablueborderforemphasis).Thisisidenticaltothatobtainedviahandcalculations.

Deflection

Foramoredetailedversionofthedeflectionofthebeam,

oFromthe'GeneralPostproc'menuselectPlotresults>ContourPlot>NodalSolution.

oSelect'DOFsolution'and'USUM'.Leavetheotherselectionsasthedefaultvalues.Click'OK'.

oYoumaywanttohaveamoreusefulscale,whichcanbeaccomplishedbygoingtotheUtilityMenuandselectingPlotControls>Style>Contours>UniformContours

oThedeflectioncanalsobeobtainedasalistasshownbelow.GeneralPostproc>ListResults>NodalSolution...select'DOFSolution'and'ALLDOFs'fromthelistsinthe'ListNodalSolution'windowandclick'OK'.Thismeansthatwewanttoseealistingofalltranslationalandrotationaldegreesoffreedomfromthesolution.Ifwehadonlywantedtoseethedisplacementsforexample,wewouldhavechosen'ALLUs'insteadof'ALLDOFs'.

oAretheseresultswhatyouexpected?

Again,themaximumdeflectionoccursatnode2,therightendoftherod.Alsonotethatalltherotationalandtranslationaldegreesoffreedomwereconstrainedtozeroatnode1.

oIfyouwantedtosavetheseresultstoafile,usethemousetogotothe'File'menu(attheupperleft-handcornerofthislistwindow)andselect'Saveas'.

Stresses

Forlineelements(iebeams,spars,andpipes)youwillneedtousetheElementTabletogainaccesstoderiveddata(iestresses,strains).

oFromtheGeneralPostprocessormenuselectElementTable>DefineTable...

oClickon'Add...'