汽机热态启动操作票中英综述.docx

《汽机热态启动操作票中英综述.docx》由会员分享,可在线阅读,更多相关《汽机热态启动操作票中英综述.docx(142页珍藏版)》请在冰豆网上搜索。

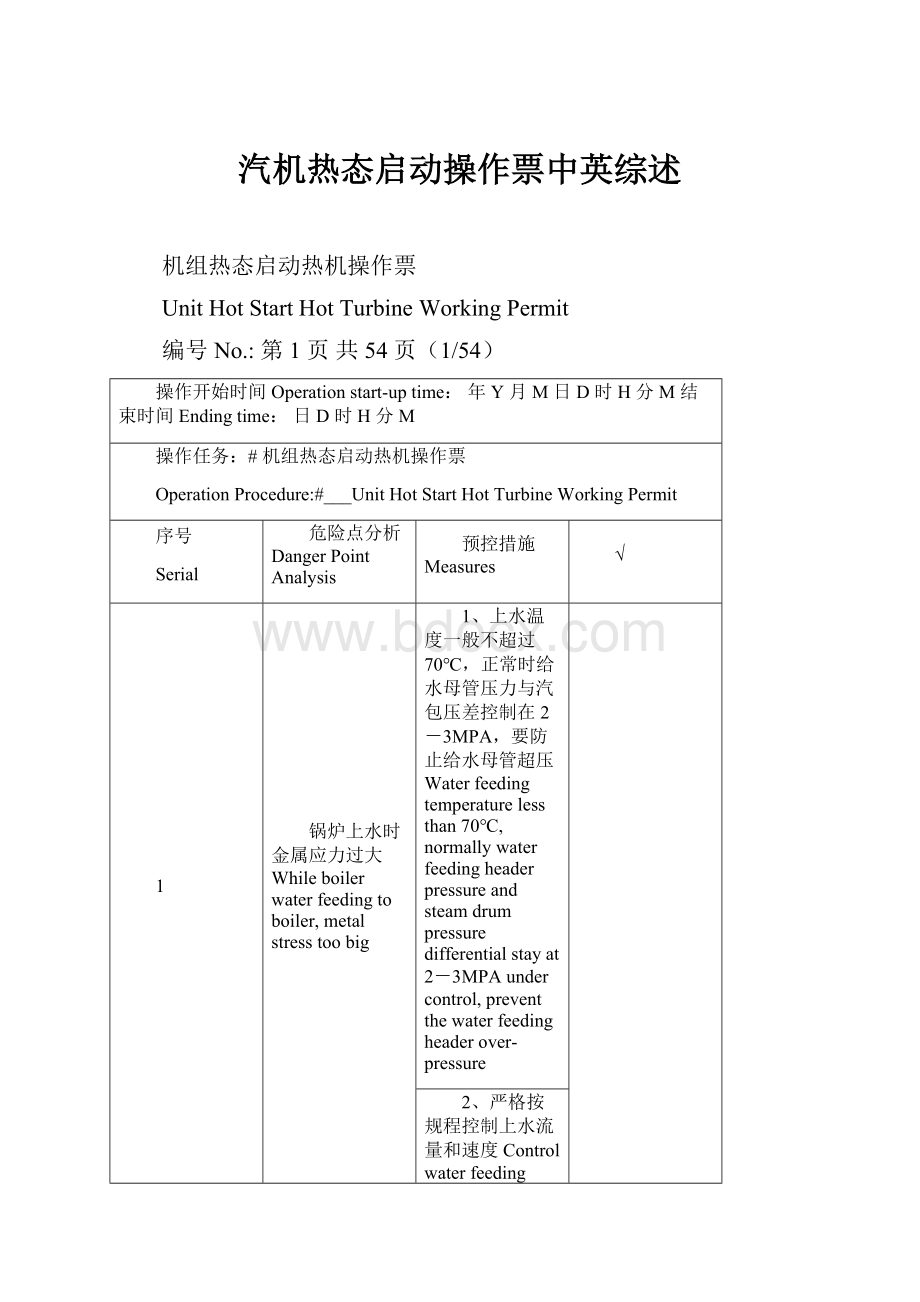

汽机热态启动操作票中英综述

机组热态启动热机操作票

UnitHotStartHotTurbineWorkingPermit

编号No.:

第1页共54页(1/54)

操作开始时间Operationstart-uptime:

年Y月M日D时H分M结束时间Endingtime:

日D时H分M

操作任务:

#机组热态启动热机操作票

OperationProcedure:

#___UnitHotStartHotTurbineWorkingPermit

序号

Serial

危险点分析DangerPointAnalysis

预控措施Measures

√

1

锅炉上水时金属应力过大Whileboilerwaterfeedingtoboiler,metalstresstoobig

1、上水温度一般不超过70℃,正常时给水母管压力与汽包压差控制在2-3MPA,要防止给水母管超压Waterfeedingtemperaturelessthan70℃,normallywaterfeedingheaderpressureandsteamdrumpressuredifferentialstayat2-3MPAundercontrol,preventthewaterfeedingheaderover-pressure

2、严格按规程控制上水流量和速度Controlwaterfeedingflowrateandspeedaccordingtotheprocedure

11

投盘车时齿轮损坏Gearbrokenwhileturning

1、投盘车前应手动将盘车挂闸,并确认盘车确已挂闸啮合良好Handswitchoffwhileturning,toconfirmturningisswitchedoffandgearedwell.

12

开启轴封供汽门时管道振动Duringglandsealingstartupvibrationforthepipeline

1、稍开轴封供汽门,保持0.012~0.02MPa至少暖管10min后全开,注意充分疏水Opentheglandsealingsteamsupplyingvalveslightly,maintain0.012~0.02MPaforpipepreheatingfor10minbeforefullyopen,beattentivetowaterdrainage.

操作人(Operator)______________监护人(Supervisor)_____________

值班负责人(Responsible):

__________________值长(Shift-chief):

_______________

机组热态启动热机操作票

UnitHotStartHotTurbineWorkingPermit

编号No.:

第2页共54页(2/54)

操作开始时间Operationstart-uptime:

年Y月M日D时H分M

结束时间Endingtime:

日D时H分M

操作任务:

#机组热态启动热机操作票

OperationProcedure:

#___UnitHotStartHotTurbineWorkingPermit

序号

Serial

危险点分析DangerPointAnalysis

预控措施Measures

√

13

启动高备泵时无油压Whilestartthehighstandbypump,havingnooilpressure

1、排尽油系统内的空气Airinthesystemexhausted

14

低压缸排汽门破裂Steamventingvalvefractureforlowpressurecylinder

1、真空抽至40KPa以上时再开启主、再热蒸汽管道疏水,开疏水时注意真空变化Whenthevacuumisextractedtoabove40KPa,startthemainorreheatingsteampipelineforwaterdrainage,attentivetothevacuumchangingwhenwaterdrainageopening

2、真空抽至70KPa以上时再投入旁路Putthebypassintousewhenthevacuumisextractedtoabove70KPa

15

投入高、低压旁路时管道振动Pipevibrationwhileputtinghighorlowpressurebypassintouse.

1、锅炉压力至0.5MPa以上时投入旁路Putbypassintousewhiletheboilerpressurereachesabove0.5MPa

2、高压旁路投入时应充分暖管疏水Whilethehighpressurebypassputintouse,havethepipepreheatedenoughforwaterdrainage

3、投入高、低压旁路时应缓慢开启Slowlyputthehighorlowpressurebypassintouse

操作人(Operator)______________监护人(Supervisor)_____________

值班负责人(Responsible):

__________________值长(Shift-chief):

_______________

机组热态启动热机操作票UnitHotStartHotTurbineWorkingPermit

编号No.:

第3页共54页(3/54)

操作开始时间Operationstart-uptime:

年Y月M日D时H分M

结束时间Endingtime:

日D时H分M

操作任务:

#机组热态启动热机操作票

OperationProcedure:

#___UnitHotStartHotTurbineWorkingPermit

序号

Serial

危险点分析DangerPointAnalysis

预控措施Measures

√

16

汽轮机冲动时弯轴与水冲击Shockexistingbetweenbendingshaft

andwater.

1、汽机冲动前降低真空保护外的所有保护投入,胀差、上下缸温差合格方可冲转Whenstarttheturbineshock,reducetheallprotectionexceptthevacuumprotection,expansiondifferential,thetemperaturedifferentialbetweentheupperandbottomcylinderarequalifiedandimpulsestarting

2、冲动前汽温,汽压必须合格,保证有50以上的过热度,疏水畅通Beforeimpulsestarting,thesteamtemperatureandpressurehavetobequalified,ensuremorethan50super-heatingdegreeandsmoothwaterdrainage.

3、轴封供汽温度合格,送轴封和抽真空前必须连续盘车Glandsealingsteamsupplytemperaturequalified,continuousturningexecutedbeforesupplyingglandsealingandvacuumextraction

4、启动过程中机组应正常,当振动大跳闸时,应立即破坏真空紧急停机,查明原因Theunitshouldbenormalduringstartup,whenthereisvibrationandbigtrip,destroythevacuumimmediatelytoshutdownurgently,andcheckthereasonforthat.

5、启动过程中,汽温急剧下降应打闸停机Duringstart-up,ifsteamtemperaturedecreasesacutely,switchofftoshutdown.

17

机组冲动过程的振动Vibrationduringunitimpulse

1、迅速平稳的通过临界转速,当振动跳闸时,应立即回到盘车状态查明原因,不得降速暖机和硬闯临界转速。

Whileexceedingthecriticalrotationspeedandtrippingforthevibrationhappens,changeintoturningstatetocheckthereasonforthat,neverspeeddowntopreheatorkeeprunningwhileexceedingcriticalrotationspeed.

操作人(Operator)______________监护人(Supervisor)_____________

值班负责人(Responsible):

__________________值长(Shift-chief):

_______________

机组热态启动热机操作票

UnitHotStartHotTurbineWorkingPermit

编号No.:

第4页共54页(4/54)

操作开始时间Operationstart-uptime:

年Y月M日D时H分M

结束时间Endingtime:

日D时H分M

操作任务:

#机组热态启动热机操作票

OperationProcedure:

#___UnitHotStartHotTurbineWorkingPermit

序号

Serial

危险点分析DangerPointAnalysis

预控措施Measures

√

18

机组冲动后盘车脱不开Theturninggearkeepengagedafterunitimpulse

1、设专人监视,当盘车未能脱开时,立即打闸停机Supervisorappointed,whenturninggearengaged,instantlyswitchofftoshutdown

19

机组定速后停止调整油泵和润滑油泵时,调整油压润滑油压力下降Whenunitstayatsteadyspeedandstoptheadjustmentoftheoilpumpandlubeoilpump,lubeoilforoilpressureadjustmentdecreaseitspressure.

1、停油泵时密切注意油压变化,如油压下降及时启动油.迅速查明原因Payattentiontotheoilpressurechangingtightlywhenstoppingtheoilpump,iftheoilpressurelower,startuptheoil,checkthereasonforthat.

20

油温波动大Oiltemperaturefluctuategreatly

1、冲动时设专人调整润滑油温,保证油温在35~45℃,防止油温波动过大Specialpersonsappointedtoadjustthelubeoiltemperatureduringimpulsetoensurethetemperaturemaintainingat35to45centigrade,topreventitfromfluctuatinggreatly.

操作人(Operator)______________监护人(Supervisor)_____________

值班负责人(Responsible):

__________________值长(Shift-chief):

_______________

机组热态启动热机操作票

UnitHotStartHotTurbineWorkingPermit

编号No.:

第5页共54页(5/54)

操作开始时间Operationstart-uptime:

年Y月M日D时H分M

结束时间Endingtime:

日D时H分M

操作任务:

#机组热态启动热机操作票

OperationProcedure:

#___UnitHotStartHotTurbineWorkingPermit

序号

Serial

危险点分析DangerPointAnalysis

预控措施Measures

√

21

发电机并列后风温升高

Airtemperatureascendingaftergeneratorsparallel

1、发电机并列后,视风温情况,及时开启投入氢冷器,开启出口门前放空气门,排尽空气Whengeneratorscometoparallel,dependingontheairtemperature,intimestartupandputthehydrogencoolerintouse,startuptheairventingvalveattheoutlettoexhaustalltheair.

22

汽轮机负荷过程中出现振动Vibrationinturbineload

1、发现各轴承振动增大时,停止加负荷或减少负荷直至振动消除为止,并在此负荷下暖机30min,再进行加负荷.Whenwefindthevibrationforeachbearingincreases,stopincreasingorreducingloaduntilthevibrationdisappears,andpreheatingundertheloadfor30minutes,andthenincreasetheload.

23

机组启动过程中上,下缸温差超过规定值Temperaturedifferentialbetweenupperanddowncylinderexceedsspecifiedvalueduringstart-up.

严格按规程要求的启动曲线控制加负荷速度及暖机时间,如温差超过51℃,并继续上升且无法消除时,应立即停机。

Obeyingthestart-upcurvestrictlytocontrolloadincreasingrateandpreheatingtime,ifthetemperaturedifferentialexceeds51centigrade,andcontinuetoascendandcan’tbeeliminated,shutdownquickly.

24

关闭疏水手动门时的人身伤害Personnelsafetythreatenedwhileclosingwaterdrainagemanualvalve

1、不要面对疏水门,以免由于盘根嗤开造成烫伤Don’tstayinfaceofwaterdrainagevalvetoavoidburnsfromthepackingopened.

操作人(Operator)______________监护人(Supervisor)_____________

值班负责人(Responsible):

__________________值长(Shift-chief):

_______________

机组热态启动热机操作票

UnitHotStartHotTurbineWorkingPermit

编号No.:

第6页共54页(6/54)

操作开始时间Operationstart-uptime:

年Y月M日D时H分M

结束时间Endingtime:

日D时H分M

操作任务:

#机组热态启动热机操作票

OperationProcedure:

#___UnitHotStartHotTurbineWorkingPermit

序号

Serial

操作内容OperationProcedure

√

时间Time

操作人

一、锅炉点火前的检查与准备:

Inspectionandpreparationbeforeignitionforboiler

1

影响机组启动的检修工作已结束,相关工作票已终结,对机组主、辅设备进行全面检查,机组符合启动条件Theoverhaulingaffectingtheunitstart-uphasfinished,relativeworkingpermithasexpired,makeoverallinspectionformainorauxiliaryequipmentoftheunitwhichshouldmeettherequirementofstart-up.

2

主、辅机各保护联锁试验完成且合格,各保护、报警及所有仪表均应正常投入Protectioninterlocktestformainorauxiliarymachinehasbeenfinishedandqualified,everyprotection,alarmandallthegaugesshouldworknormally

3

热控各远方控制、监测报警系统(包括联锁保护)以及各就地控制系统都正常完好Thethermalcontrolremotecontrol,monitoringalarmsystemincludinginterlockprotectionandlocalcontrolsystemworkingnormally

4

各有关的转动机械设备(包括备用设备)、电磁阀、电动阀门等控制电源、操作电源、仪表电源等均应送电且经试操作正常Everyrunningmachineequipmentincludingstandbyequipment,solenoidvalve,electricvalve(controlpowersupply)

5

各辅机就地事故按钮均已复位,各辅机相关系统检查完好,符合投入条件Eachauxiliarylocalaccidentshouldbereset,relativesystemforeachauxiliarymachineshouldmeettherequirementofthestartingup.

操作人(Operator)______________监护人(Supervisor)_____________

值班负责人(Responsible):

__________________值长(Shift-chief):

_______________

机组热态启动热机操作票

UnitHotStartHotTurbineWorkingPermit

编号No.:

第7页共54页(7/54)

操作开始时间Operationstart-uptime:

年Y月M日D时H分M

结束时间Endingtime:

日D时H分M

操作任务:

#机组热态启动热机操作票

OperationProcedure:

#___UnitHotStartHotTurbineWorkingPermit

序号

Serial

操作内容OperationProcedure

√

时间Time

操作人

6

检查汽机手动遮断手柄在“遮断”位置,机械超速试验手柄在“正常”位置,盘车装置手柄在“停用”位置Checktheturbinemanualtriphandleshouldstayattripstatus,themachineoverspeedtesthandleshouldstayatnormalstatus,turninggearhandleshouldstayatstopstatus.

7

辅汽系统暖管结束后投入运行,维持辅汽联箱压力在0.65~0.85MPa:

Auxiliarysteamsystemundergoingpreheatingandthenputintouse,maintainitsheaderpressureat0.65~0.85MPa.

8

联系值长,要求化学加强制水,保证机组启动用水足够Contacttheshiftchief,requireforchemicalstrengtheningwaterpreparation,ensureenoughwaterforunitstart-up.

9

检查主机润滑油油箱油位mm,小机润滑油油箱油位mm,油质是否合格,否则投入滤油系统运行Inspectthemainmotorlubeoiltanklevel___mm,smallmotorlubeoiltanklevel___mm,andwhetheroilisqualifiedornot,orelseputtheoilfiltrationsystemintouse.

操作人(Operator)______________监护人(Supervisor)_____________

值班负责人(Responsible):

__________________值长(Shift-chief):

_______________

机组热态启动热机操作票

UnitHotStartHotTurbin