稳态热分析案例ANSYS 150版.docx

《稳态热分析案例ANSYS 150版.docx》由会员分享,可在线阅读,更多相关《稳态热分析案例ANSYS 150版.docx(14页珍藏版)》请在冰豆网上搜索。

稳态热分析案例ANSYS150版

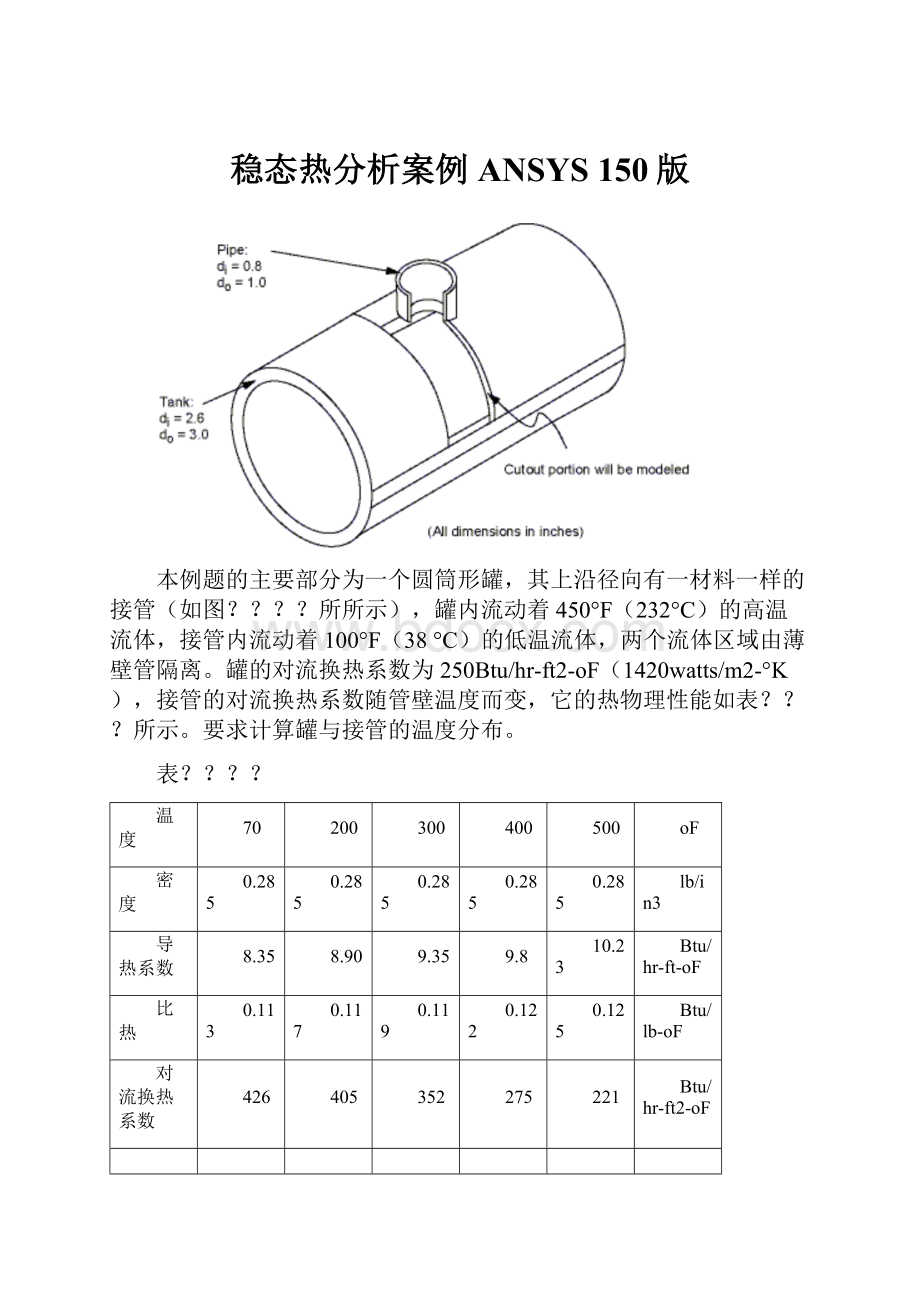

本例题的主要部分为一个圆筒形罐,其上沿径向有一材料一样的接管(如图?

?

?

?

所所示),罐内流动着450°F(232°C)的高温流体,接管内流动着100°F(38°C)的低温流体,两个流体区域由薄壁管隔离。

罐的对流换热系数为250Btu/hr-ft2-oF(1420watts/m2-°K),接管的对流换热系数随管壁温度而变,它的热物理性能如表?

?

?

所示。

要求计算罐与接管的温度分布。

表?

?

?

?

温度

70

200

300

400

500

oF

密度

0.285

0.285

0.285

0.285

0.285

lb/in3

导热系数

8.35

8.90

9.35

9.8

10.23

Btu/hr-ft-oF

比热

0.113

0.117

0.119

0.122

0.125

Btu/lb-oF

对流换热系数

426

405

352

275

221

Btu/hr-ft2-oF

6.5.1预处理

Step1:

确定分析标题

起动ANSYS后,开始一个分析,需要输入一个标题,按下面方法进行操作:

1.选择Utility Menu>File>ChangeTitle,弹出相应对话框

2.输入 Steady-statethermalanalysisofpipejunction。

3.点击OK。

Step2:

设置分析单位系统

Youneedtospecifyunitsofmeasurementfortheanalysis.Forthispipejunctionexample,measurementsusetheU.S.Customarysystemofunits(basedoninches).Tospecifythis,typethecommand /UNITS,BINintheANSYSInputwindowandpressENTER.在分析之前,需要为分析系统设定单位系统,

Step3:

DefinetheElementType

Theexampleanalysisusesathermalsolidelement.Todefineit,dothefollowing:

1.Choose Main Menu>Preprocessor>ElementType>Add/Edit/Delete.TheElementTypesdialogboxappears.

2.ClickonAdd.TheLibraryofElementTypesdialogboxappears.

3.Inthelistontheleft,scrolldownandpick(highlight)"ThermalSolid."Inthelistontheright,pick"Brick20node90."

4.ClickonOK.

5.ClickonClosetoclosetheElementTypesdialogbox.

Step4:

DefineMaterialProperties

Todefinematerialpropertiesfortheanalysis,performthesesteps:

1.Choose Main Menu>Preprocessor>MaterialProps>MaterialModels.TheDefineMaterialModelBehaviordialogboxappears.

2.IntheMaterialModelsAvailablewindow,double-clickonthefollowingoptions:

Thermal,Density.Adialogboxappears.

3.Enter.285forDENS(Density),andclickonOK.MaterialModelNumber1appearsintheMaterialModelsDefinedwindowontheleft.

4.IntheMaterialModelsAvailablewindow,double-clickonthefollowingoptions:

Conductivity,Isotropic.Adialogboxappears.

5.ClickontheAddTemperaturebuttonfourtimes.Fourcolumnsareadded.

6.IntheT1throughT5fields,enterthefollowingtemperaturevalues:

70,200,300,400,and500.Selecttherowoftemperaturesbydraggingthecursoracrossthetextfields.ThencopythetemperaturesbypressingCtrl-c.

7.IntheKXX(ThermalConductivity)fields,enterthefollowingvalues,inorder,foreachofthetemperatures,thenclickonOK.Notethattokeeptheunitsconsistent,eachofthegivenvaluesofKXXmustbedividedby12.YoucanjustinputthefractionsandhaveANSYSperformthecalculations.

8.35/12

8.90/12

9.35/12

9.80/12

10.23/12

8.IntheMaterialModelsAvailablewindow,double-clickonSpecificHeat.Adialogboxappears.

9.ClickontheAddTemperaturebuttonfourtimes.Fourcolumnsareadded.

10.WiththecursorpositionedintheT1field,pastethefivetemperaturesbypressingCtrl-v.

11.IntheC(SpecificHeat)fields,enterthefollowingvalues,inorder,foreachofthetemperatures,thenclickonOK.

.113

.117

.119

.122

.125

12.Choosemenupath Material>NewModel,thenenter2forthenewMaterialID.ClickonOK.MaterialModelNumber2appearsintheMaterialModelsDefinedwindowontheleft.

13.IntheMaterialModelsAvailablewindow,double-clickonConvectionorFilmCoef.Adialogboxappears.

14.ClickontheAddTemperaturebuttonfourtimes.Fourcolumnsareadded.

15.WiththecursorpositionedintheT1field,pastethefivetemperaturesbypressingCtrl-v.

16.IntheHF(FilmCoefficient)fields,enterthefollowingvalues,inorder,foreachofthetemperatures.Tokeeptheunitsconsistent,eachvalueofHFmustbedividedby144.Asinstep7,youcaninputthedataasfractionsandletANSYSperformthecalculations.

426/144

405/144

352/144

275/144

221/144

17.ClickontheGraphbuttontoviewagraphofFilmCoefficientsvs.temperature,thenclickonOK.

18.Choosemenupath Material>Exit toremovetheDefineMaterialModelBehaviordialogbox.

19.ClickonSAVE_DBontheANSYSToolbar.

Step5:

DefineParametersforModeling

1.Choose Utility Menu>Parameters>ScalarParameters.TheScalarParameterswindowappears.

2.Inthewindow'sSelectionfield,enterthevaluesshownbelow.(Donotenterthetextinparentheses.)PressENTERaftertypingineachvalue.Ifyoumakeamistake,simplyretypethelinecontainingtheerror.

RI1=1.3(Insideradiusofthecylindricaltank)

RO1=1.5(Outsideradiusofthetank)

Z1=2(Lengthofthetank)

RI2=.4(Insideradiusofthepipe)

RO2=.5(Outsideradiusofthepipe)

Z2=2(Lengthofthepipe)

3.ClickonClosetoclosethewindow.

Step6:

CreatetheTankandPipeGeometry

1.Choose Main Menu>Preprocessor>Modeling>Create>Volumes>Cylinder>ByDimensions.TheCreateCylinderbyDimensionsdialogboxappears.

2.Setthe"Outerradius"fieldto RO1,the"Optionalinnerradius"fieldto RI1,the"Zcoordinates"fieldsto 0 and Z1 respectively,andthe"Endingangle"fieldto 90.

3.ClickonOK.

4.Choose Utility Menu>WorkPlane>OffsetWPbyIncrements.TheOffsetWPdialogboxappears.

5.Setthe"XY,YZ,ZXAngles"fieldto 0,-90.

6.ClickonOK.

7.Choose Main Menu>Preprocessor>Modeling>Create>Volumes>Cylinder>ByDimensions.TheCreateCylinderbyDimensionsdialogboxappears.

8.Setthe"Outerradius"fieldto RO2,the"Optionalinnerradius"fieldto RI2,the"Zcoordinates"fieldsto 0 and Z2 respectively.Setthe"Startingangle"fieldto -90and the"EndingAngle"to0.

9.ClickonOK.

10.Choose Utility Menu>WorkPlane>AlignWPwith>GlobalCartesian.

Step7:

OverlaptheCylinders

1.Choose Main Menu>Preprocessor>Modeling>Operate>Booleans>Overlap>Volumes.TheOverlapVolumespickingmenuappears.

2.ClickonPickAll.

Step8:

ReviewtheResultingModel

Beforeyoucontinuewiththeanalysis,quicklyreviewyourmodel.Todoso,followthesesteps:

1.Choose Utility Menu>PlotCtrls>Numbering.ThePlotNumberingControlsdialogboxappears.

2.ClicktheVolumenumbersradiobuttontoOn,thenclickonOK.

3.Choose Utility Menu>PlotCtrls>ViewSettings>ViewingDirection.Adialogboxappears.

4.Setthe"Coordsofviewpoint"fieldsto(-3,-1,1),thenclickonOK.

5.Reviewtheresultingmodel.

6.ClickonSAVE_DBontheANSYSToolbar.

Step9:

TrimOffExcessVolumes

Inthisstep,deletetheoverlappingedgesofthetankandthelowerportionofthepipe.

1.Choose Main Menu>Preprocessor>Modeling>Delete>VolumeandBelow.TheDeleteVolumeandBelowpickingmenuappears.

2.Inthepickingmenu,type3,4andpresstheENTERkey.ThenclickonOKintheDeleteVolumeandBelowpickingmenu.

Step10:

CreateComponentAREMOTE

Inthisstep,youselecttheareasattheremoteYandZedgesofthetankandsavethemasacomponentcalledAREMOTE.Todoso,performthesetasks:

1.Choose Utility Menu>Select>Entities.TheSelectEntitiesdialogboxappears.

2.Inthetopdropdownmenu,selectAreas.Intheseconddropdownmenu,selectByLocation.ClickontheZCoordinatesradiobutton.

3.Setthe"Min,Max"fieldto Z1.

4.ClickonApply.

5.ClickontheYCoordinatesandAlsoSeleradiobuttons.

6.Setthe"Min,Max"fieldto 0.

7.ClickonOK.

8.Choose Utility Menu>Select>Comp/Assembly>CreateComponent.TheCreateComponentdialogboxappears.

9.Setthe"Componentname"fieldto AREMOTE. Inthe"Componentismadeof"menu,selectAreas.

10.ClickonOK.

Step11:

OverlayLinesonTopofAreas

Dothefollowing:

1.Choose Utility Menu>PlotCtrls>Numbering.ThePlotNumberingControlsdialogboxappears.

2.ClicktheAreaandLinenumberradioboxestoOnandclickonOK.

3.Choose Utility Menu>Plot>Areas.

4.Choose Utility Menu>PlotCtrls>EraseOptions.

5.Set"ErasebetweenPlots"radiobuttontoOff.

6.Choose Utility Menu>Plot>Lines.

7.Choose Utility Menu>PlotCtrls>EraseOptions.

8.Set"ErasebetweenPlots"radiobuttontoOn.

Step12:

ConcatenateAreasandLines

Inthisstep,youconcatenateareasandlinesattheremoteedgesofthetankformappedmeshing.Todoso,followthesesteps:

1.Choose Main Menu>Preprocessor>Meshing>Mesh>Volumes>Mapped>Concatenate>Areas.TheConcatenateAreaspickingmenuappears.

2.ClickonPickAll.

3.Choose Main Menu>Preprocessor>Meshing>Mesh>Volumes>Mapped>Concatenate>Lines.Apickingmenuappears.

4.Pick(clickon)lines12and7(orenterinthepicker).

5.ClickonApply.

6.Picklines10and5(orenterinpicker).

7.ClickonOK.

Step13:

SetMeshingDensityAlongLines

1.Choose Main Menu>Preprocessor>Meshing>SizeCntrls>ManualSize>Lines>PickedLines.TheElementSizeonPickedLinespickingmenuappears.

2.Picklines6and20(orenterinthepicker).

3.ClickonOK.TheElementSizesonPickedLinesdialogboxappears.

4.Setthe"No.ofelementdivisions"fieldto4.

5.ClickonOK.

6.Choose Main Menu>Preprocessor>Meshing>SizeCntrls>ManualSize>Lines>PickedLines.Apickingmenuappears.

7.Pickline40(orenterinthepicker).

8.ClickonOK.TheElementSizesonPickedLinesdialogboxappears.

9.Setthe"No.ofelementdivisions"fieldto6.

10.ClickonOK.

Step14:

MeshtheModel

Inthissequenceofsteps,yousettheglobalelementsize,setmappedmeshing,thenmeshthevolumes.

1.Choose Utility Menu>Select>Everything.

2.Choose Main Menu>Preprocessor>Meshing>SizeCntrls>ManualSize>Global>Size.TheGlobalElementSizesdialogboxappears.

3.Setthe"Elementedgelength"fieldto0.4andclickonOK.

4.Choose Main Menu>Preprocessor>Meshing>MesherOpts.TheMesherOptionsdialogboxappears.

5.SettheMesherTyperadiobuttontoMappedandclickonOK.TheSetElementShapedialogboxappears.

6.Inthe2-Dshapekeydropdownmenu,selectQuadandclickonOK.

7.ClickontheSAVE_DBbuttonontheT