DEK印刷机操作指引.docx

《DEK印刷机操作指引.docx》由会员分享,可在线阅读,更多相关《DEK印刷机操作指引.docx(24页珍藏版)》请在冰豆网上搜索。

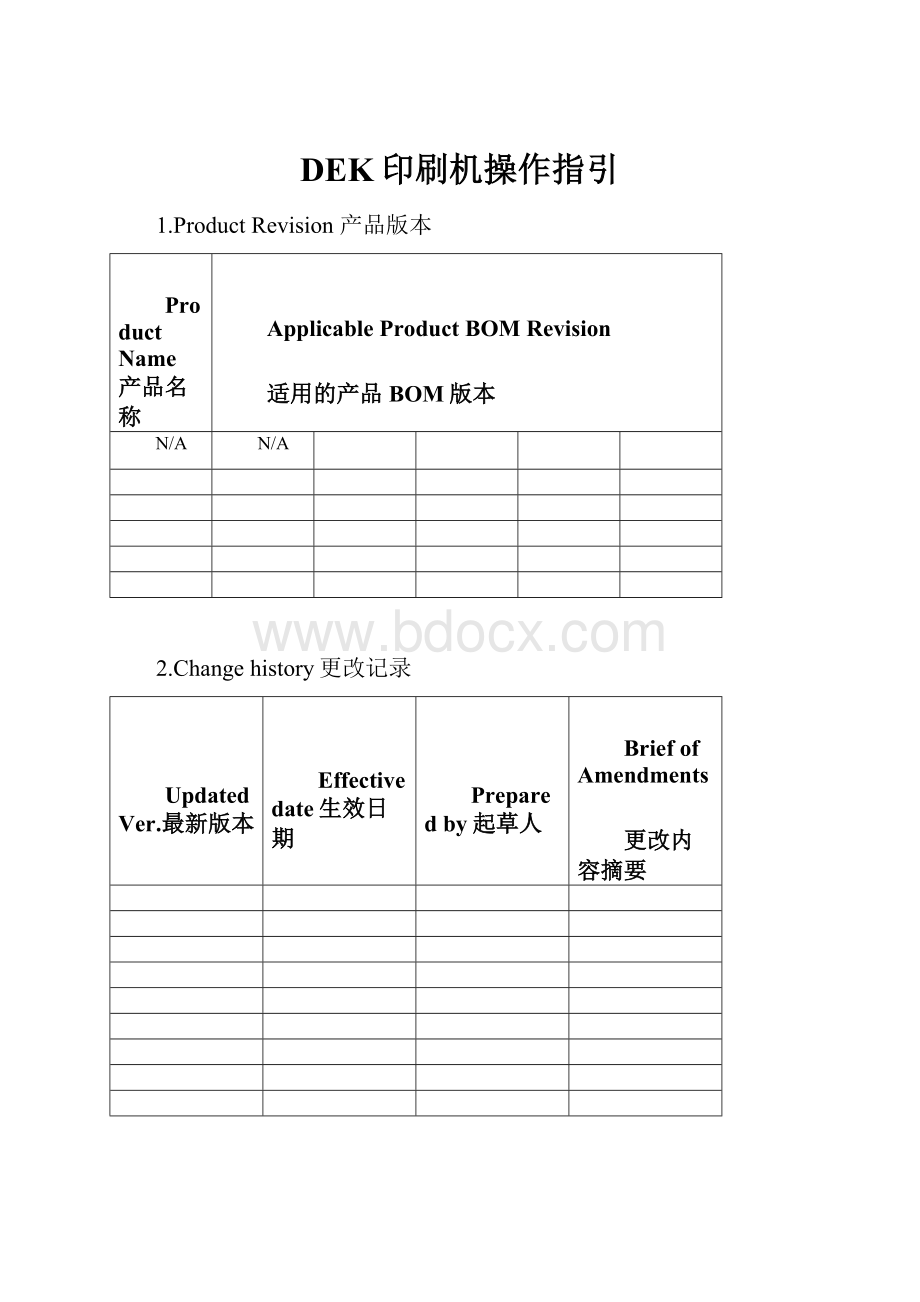

DEK印刷机操作指引

1.ProductRevision产品版本

ProductName产品名称

ApplicableProductBOMRevision

适用的产品BOM版本

N/A

N/A

2.Changehistory更改记录

UpdatedVer.最新版本

Effectivedate生效日期

Preparedby起草人

BriefofAmendments

更改内容摘要

3.Purpose目的

ToprovidestandardoperatinginstructionsfortheDEK265Horizon.

4.ScopeX围

ThisdocumentappliestoallmanufacturingsitesthatutilizetheDEK265Horizon.

5.Definitions定义

IPC-T-50-TermsandDefinitionsforInterconnectingandPackagingElectronicCircuits

6.Responsibilities职责

N/A

7.Description描述

1.1.ProcessFlow

1.2.MachineStart-Up

1.2.1.EnsurethatallE-stopsareintheonposition.Themachinehas2E-stopsoneonsideofthefrontpanel.(SeeFigure1.0)

Figure1.0:

LocationofE-stops

1.2.2.Turnmainpowerswitchclockwise¼turn.Indicatorshouldbepointedupward.(SeeFigure2.0)

1.2.2.1.1.1.1.1.1.Figure2.0MainPowerSwitchonFrontonMachine

1.2.3.Tologontype:

“ADMINISTRATOR”intheuserfieldand“administrator”inthepasswordfield(SeeFigure2.1)

Figure2.1

1.2.4.WhenTheNetworklogonboxappearsclickontheOKbutton(Figure2.2)

1.2.5.ClickontheDEKicontostarttheprinter

1.2.6.Whenprompted,PressblueSystemButtonlocatedjustabovethekeyboard.(Figure3.0)

Figure3.0

1.2.7.TouchtheMonitorsquareonthescreenorF7ontheKeyboard(SeeFigure4.0Location1).

Figure4.0

1.2.8.TouchtheLogOnsquareonthescreenorF1onthekeyboard.(Figure5.0Location1)

Figure5.0

1.2.9.TypeyournameintoOperatorLogonBox(See⇐inFigure5.0)

1.2.10.Touch“Exit”onthescreenorpressF8onthekeyboard(SeeFigure5.0Location2)

1.MACHINEOPERATION

1.3.ProcessFlow

1.4.LoadingProgram

1.4.1.PresstheSetupboxonthetouchscreenorF6onthekeyboard.(SeeFigure4.0Location2)

1.4.2.PresstheLoadDataboxontheScreenorF2onthekeyboard.(SeeFigure6.0Location1)

Figure6.0

1.4.3.Highlighttherequiredfilefortheassemblytoberun.ThecorrectfilenamefortheassemblytoberuncanbefoundinthelinefilesuppliedbytheCAMdepartment.(See⇐infigure7.0)

Figure7.0

1.4.4.PresstheLoadboxonthescreenorF1onthekeyboard.(SeeFigure7.0Location1)

1.4.5.PresstheExitboxonthescreenorF8onthekeyboard.(SeeFigure7.0Location2)Thestepmustbepletedfortheprogramtoproperlyload.

1.5.SupportTooling

1.5.1.PresstheSetupBoxonthescreenorF6onthekeyboard.(SeeFigure4.0,Location1)

1.5.2.PresstheChangeToolingboxonthescreenorF6onthekeyboard.(SeeFigure6.0,Location2)

1.5.3.SideATooling

1.5.3.1.PresstheOpenCoverboxonthescreenorF2ontheKeyboard(Figure8.0,Location1)thenopentheprintheadcover.(Figure9.0).

Figure8.0

Figure9.0

1.5.3.2.Placeflattoolingblocksorpinsbetweenrailsinareaboardwillrun.(Figure10.0)

1.5.3.3.Closethecover.

1.5.3.4.Pressthebluesystembutton.

1.5.3.5.PressExit.

1.5.3.6.PressHomeCleaner.

Figure10.0

1.5.4.SideBTooling

1.5.4.1.PresstheHomeCleanerboxontheScreenorF3ontheKeyboard.(Figure8.0,Location2)

1.5.4.2.PresstheBoardStopboxonthescreenorF4onthekeyboard.(Figure11.0,Location1)

1.5.4.3.PresstheOpenCoverboxonthescreenorF2onthekeyboard,(Figure9.0,Location1)thenopentheprintheadcover.(Figure10.0).

1.5.4.4.PresstheBoardClampsboxonthescreenorF3onthekeyboard.(Figure11.0,Location2)

1.5.4.5.PlaceaPCBontheRailsandpushintothemachineuntilitmeetstheboardstop.

1.5.4.6.PressboardClampsandclosethecover.

1.5.4.7.Pressbluesystembutton.

1.5.4.8.PressExit.

1.5.4.9.PressHomeCamera.

1.5.4.10.PressOpenCover

1.5.4.11.AlignamylartothePCBandtapetotherailswithmaskingtape.

1.5.4.12.RefertotheAssemblyBuildInstructiontodetermineifacustomtoolingplateisrequired.Alignthecustomtoolingplateoruniversaltoolingpinsorblockstotheopenareasonthemylar.

1.5.4.13.Removethemylar,ClosethecoverandPressExit

Figure11.0

1.6.StencilLoading

1.6.1.PresstheSetupBoxonthescreenorF6onthekeyboard.(SeeFigure4.0,Location1)

1.6.2.PresstheChangeScreenboxonthescreenorF5onthekeyboard.(SeeFigure6.0,Location3)

1.6.3.Opentheprintheadcover(Figure9.0)andremovetheexistingscreenifneeded.(Figure12.0).

Figure12.0

1.6.4.Loadanewstencilintotheprinter.Ensurecorrectorientationandprintjustification.(Figure13).

Figure13

1.6.5.Closethefrontprintheadcover(Figure14)andpressthebluesystembutton.(Figure3.0)

Figure14

1.6.6.PresstheChangeScreenboxonthescreenorF5onthekeyboard.(Figure6.0,Location3)

1.6.7.PresstheExitboxonthescreenorF8onthekeyboard.(Figure6.0,Location4)

1.6.8.PresstheExitboxonthescreenorF8onthekeyboard.(Figure8.0,Location3).

1.7.LoadTheSolderPaste

1.7.1.PressPasteLoad.

1.7.2.PressManualLoad.

1.7.3.OpenCoverandLoadPaste.

1.7.4.Depositabeadjustinfrontofthestencilimage.

1.7.5.ClosethecoverandPresstheBluesystembutton.

1.7.6.PressContinue.

1.7.7.PressExit.

1.8.SqueegeeLoading

1.8.1.PressSetup.

1.8.2.PressChangeSqueegee.

1.8.3.OpentheCoverandchangethesqueegees.

1.8.4.ClosethecoverandPresstheBluesystembutton.

1.8.5.PressContinue.

1.8.6.PressExit.

2.Paperloading

1.9.PressOpenCover.

1.10.PressChangeScreen.

1.11.RemovetheStencil.

1.12.Lifttheemptytubefromthecleaner.

1.13.Removethespindlesfromeachend.

1.14.Removethetakeuproll.

1.15.Rotatetheflange1/4turntounlockthepaperroll.

1.16.Slidethedirtypaperfromtheshaft.

1.17.Slidetheleftendoftheemptyshaftintothecleanerendplate.

1.18.Placetherightendoftheshaftintothemotordrivespindle.

1.19.Placethepaperspindlesintobothendsofthenewpaperroll.

1.20.Installtherollinthefrontofthecleaner.Thepapershouldberoutedfromunderneath.

1.21.

Installthepaperasshowninthediagram.

1.22.Slidethepaperthroughtherearshaft.

1.23.PressPrimePaper.

1.24.Pressthetwo-buttoncontroluntiltheslackisoutofthepaper.

1.25.Reinstallthestencil.

3.Solventloading

1.26.PressOpenCover.

1.27.PressChangeScreen.

1.28.RemovetheStencil.

1.29.RemovethecapfromtheReservoir.

1.30.Addsolventtothereservoir.

1.31.Replacethecap.

1.32.PressPrimeSolvent.

1.33.Pressthetwobuttoncontrolsuntilthepaperbeeswet.

1.34.Reinstallthestencil

4.ShutDown

1.35.PressE-Stop.

1.36.ClickontheCloseSystemIcon.

1.37.ClickonStart.

1.38.ClickonShutdown.

1.39.Waitforwindowstoshutdownproperly.

1.40.Turnofthemainpowerswitch.

5.Troubleshooting

1.41.FiducialFindFailure

Cleanthefiducialwithapencileraserandretry.

1.42.PressureError

1.42.1.ReprintthePCBuntiltheerrorsarecleared.

1.42.2.Inspecttheboardandwashifnecessary.

1.42.3.Cleanthebottomofthestencil

1.43.PasteMissingOnThePCB

Addmoresolderpastetothestencil

1.44.BadPasteRegistration

Gettechnicalsupport.

1.45.TransferError

Adjustconveyorsandretry.

1.46.SolventLow

Addsolventperinstruction

1.47.PaperEmpty

Loadpaperperinstruction

6.DatacaptureREQUIREMENTS

1.48.TheREADINGS.DEKfilemustbemanipulatedtoestablishthePrintingprocessperformanceofanAssemblyontheDEK265Horizon.

1.49.TheREADINGS.DEKfileislocatedonthelocaldrive,whichmustberenamedaftereachassemblyhasbeenpleted.

1.50.Ifthisisnotcarriedoutbeforethesetupofthenextbatchitwillcontinuewiththedataloggingprocessandthereforebeunabletoestablishwhichassemblyhasbeenrun.

1.51.Thefileshouldbenamedwiththeassemblynumberdateandsamplenumberasshownbelow:

-

716320—WO12345-201205

7.2DDATALOGGINGSETUP

Tostartthedataloggingofthe2Dinspectionthefollowingstepsmustbetaken:

-

1.PressF8Maint.

2.PressF7Testcycles

3.PressF6Dataloggertoswitchthe2Dinspectionon

4.PressF1Run

8.EVENTLOGGING

1.52.Theeventlogdetailstheactuallocationsthathavefailedoutsidethecontrolparameters.Onadailybasisthefollowingroutinemustbefollowed:

1.F8Maint.

2.F4Housekeeping

3.F6Deletedata

4.F1Run

1.53.AfterthebatchhasruntheeventlogmustbecopiedandmovedtotheSPCdatafolder.

1.54.Thefileshouldbenamedwiththeassemblynumberdateandsamplenumberasshownbelow:

716320—WO12345-201205

8.SafetyandEnvironmentalRequirements安全和环境要求

N/A无

9.ReferenceDocument参考文件

N/A无

10.Records记录

SolderpasteuserecordsQF-00066.

锡膏使用记录表QF-00066。

11.Appendix附件

N/A无