化工厂常用PSSR检查表文档格式.docx

《化工厂常用PSSR检查表文档格式.docx》由会员分享,可在线阅读,更多相关《化工厂常用PSSR检查表文档格式.docx(78页珍藏版)》请在冰豆网上搜索。

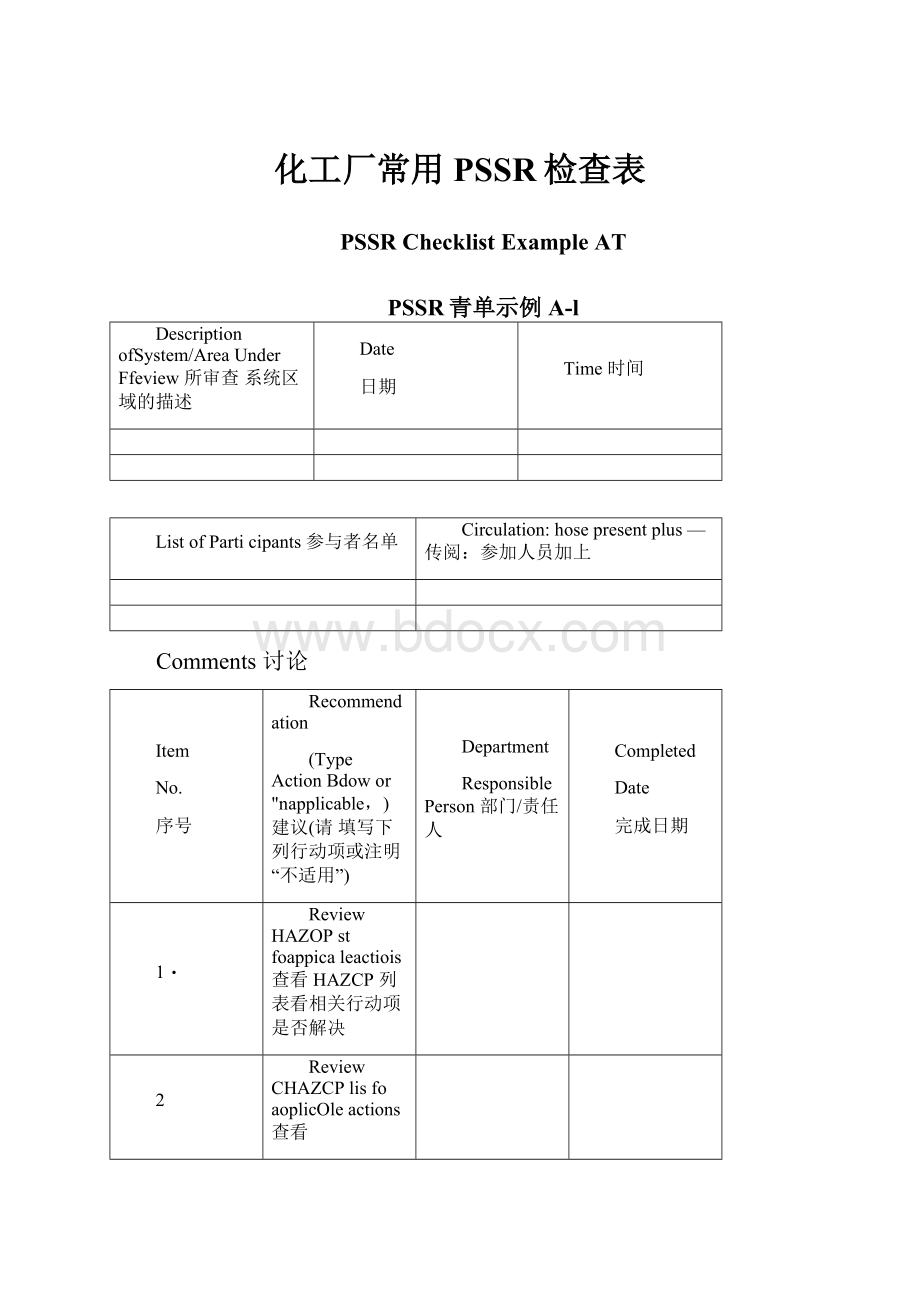

完成质量保证体系并建立了文档

a)Recei\edecuipment=purchased收到的设备购买的设备

d)Adherencetoctesigidrawings/spscifictians

vT/mAAi5:

|.4>

fi1姑

c)Msteriasoconstuctioi施工材料

d)Workmanship工艺技术

iem

No.序号

nqrtplicable"

)建议(请填写下列行动项或注明“不适用”)

Department/ResponsiblePerson部门/责任人

D£

e完成日期

Equipmentconponertsceckojttcnimisianing(cbciment)

设备部件检査调试(文牛)

9

Loopandirtelock/permisBive/alam:

sepoina(CustnentandtestingdocimentesUts)

回路和联锁许可/报警:

设置点调整禾测试(文档记录)

10

[nstumentc^ibri(nsd)neandcCclmenteC仪表校订完成并记录

11

VaidaicnprciSddevecped,qDproved制定、批准和执行的验证椒

12

Pressuretestingcbneandcocumerted压力测试完成并记录

13

Systemcleanedandflished系统已完成清扫、冲洗

14

sy>

tens[①匹上由,亦申肛6-661刚

4811I611£

血povidsd

、出『乍力分心木+f•若

15

▼91打1百0阳2上旳$aiaiced通风系统已平衡

16

PerfdlmancecheckcutoloaeXhaustsytems局部排气系统的性能检测

17

Vibrioimeasurements/(Ocument^ib"

振动测量记录

18

7iddaCiogra"

hydcneanCasequired

现场放射性物质检测已完成H己录

19

Baselined£

asuchasthicknesseadngsfopressuevessds/ppirg基础数据,如压力容器管线的壁厚

20

Otherbaselinedta其他基础数据

21

XDTepots无损检测报告

22

Waterbatching8011*1!

)配水(记录)

EngineeringDesignD)cumentation工程设讣资

料

23

Xarr^iveofcotolplilcsophy/Sequencecf(pefatios

ha&

||筒XHIW.M;

|||石r-y口口次也:

l

24

Instumertindex

仪表索引

25

Instumertkopdagiams仪表回路图

26

safety&

non-safety)ctescrpiors联锁(安全和非安全)描述

(TypeActionBdowor'

nqrtplicable'

27.

AsbUltdaWngs:

P&

IDS,eectica,ppngnechanica竣工图:

P&

ID图,电气图,配管图,机

28

Tabdstianofpocessarms,irtelocks/ermSsivedescrpicnsandtrpswithsettigsP&

ID)

丄艺报警表、联锁许可说明表和带设定值;

ID的跳转表

29

Reviewaidaopiovalofieprctectioissystemsofesign消防系统设讣的审查和许可

30

PipngspBciftationsP&

Imechanic"

daWngs)配管图(P&

I图机械图)

31

Pressureeliedsvicesizngcacllajons安全阀规格的选定计算

32

ASMEcodepressuevessdsU1datasheets(o

Mantenance)

压力容器ASME代码UM数据表(用于维修)

33

Referencecades/staldardsfofacilitydesigi装置设计的参考规范标准

34

ReferenDecades/staldards他£

$11让恥八4曲6设备安装的参考规范标准

35

Designcodesfospecifiequipment特殊设备的设计规范

36

^elcfercetifictioi

焊工资格证书

37

XDTcetifictjon无损检测证书

38

Electrcaclasificaoidawings电器分类图

39

Electrciaicartificfecnfoclasifida^eas特定施工区域的电工资格证书

MaintenanceIfems维修项u

40

SparepaitstitsdvdcpedListeuipment:

备品备件清单并附设备清单

41

Stockequirelsparepaits备品备件所需储存设施

42

Equipmentmanuas/secificaoisto

Maintenanceard

OperatingDepatment

Wr/i攵In比Wrn砧夂丁-HR

43

Vendorprrts

供应商提供的印刷资料

44

Submitpeventiem^rienanceequestsPWs)提交的预防性维修要求

45

Servicecoitactsinface

服务合同已签订

Date完成日期

46

Trainmairienancepersonnelanldocument培训维修人员和相关培训谿

Operation"

Ifems生产项目

47

Devel(pSCPandspecifpocedues-incorporatesafetyandoperationsissss:

编写标准操作规程SOP及特殊操作规程一考虑了操作风险和可操作性『题

48

Completeclargecontiolauthoizations完成变更控制授权

49

Devel(p/isseoperatingprocedures:

制定颁布下列操作规程

a)Initiastaup初次开车

))Nomalstat-up正常开车

c)Nomaloperation正常操作

d)Normalshutdown正常停车

e)Emergencyqperatiorsinrludingemergencyshutcbwn

包括紧急停车的应急操作

f)Start-ipfooWngemergencyshutdown紧急停车后开车

g)Start-qpfooWngturnaround大修后开车

i)Nqn-butinepbcedj~esequipmentc1en-oU,equipmertplepa^atiqnf(c*mairrenance)非常规程序(设备清理、设备维修准备)

i)AuxiliayequipmentqDeraticn辅助设备的操作

50

Tranqoeratingp"

rsqnne1anddocument培训操作人员和相关培训谿

51

^rovidetechnicacoeirage技术服务范围

52

Whatistl®

probabilityfcont^nmentfOlue?

Whatarethssubsequentc(nsequences?

Reviewspllcotainment,rainwaterrurff,adfiewatercontainment・

防泄漏设施的失效概率是鈔?

失效的后果是什

ElectricalIssues电气问题

53

Panelaccess,Clearancearourdpanel,kes,etc・配电盘的通道、配电盘周围勺间隙、钥匙等

54

Cableeniysectin—gandinghousekeepinganlotherissies

电缆接入部分一密封、保洁1其他问题

55

Panelpowersauceicertifid?

Multipefeds?

配电盘电源的标识?

多源供电?

56

Spacehed:

esequied?

需要空间加热器吗?

57

Lichtinginpanels配电盘里的照明

58

Canopiesetcfooutcborpanels用于室夕卜酉1电盘的雨棚等

59

Protectionsettingsaaiillle?

有保护设置吗?

60

Panelboardschedules配电盘面板清单

61

Sparecaoacityavai1dde?

有备用容量吗?

62

PPEavailalte?

HVmstsQoves

有个人防护用品吗?

有高压fe缘垫吗?

有高压绝缘手套吗?

63

Emergency/Staidbypowerrequired?

有应急备用电源吗?

64

VSDsettigsa/alOole-factay/cammisionrlg变频器设置一工厂/调试

65

Roomaccess,

permittirnmairtairab订ityixrgess/eglessoeqLipmert

"

R丄帛、皿2/rttT、-T*A/r-g*VLZ7AA'

41-i1i'

帛H

66

PocketsforcraWngsinpanels?

配电盘的图纸集

67

Voltagewarringlabls?

电压警告标签

68

Ventilaonsufcient?

通风充足吗?

69

Sutailitforarea-IPatingGMPsitaoi1ityhazarcbusareacl^sifiation

区域适宜性一一国际防护等级、GMP适宜性、危险区域分类

・ReliefDevices

-泄放设备

70

AretherestadaidmakingsontheP&

ID?

在P&

ID图上有标准代号吗?

71

Dorelielineverttoas£

eloDation?

放空线排放到一个安全地点吗?

72

Arerelielinsandeliecb/cessecuedandadequatelysized?

放空线和泄放设备安全吗尺寸足够大吗?

73

ArethereanyisdstioivalvesWiichWIIihibit(perationcfrelievalvsifcSec?

IfYS,rominateOperstiorstomonito・ecordno

有处于关闭状态会抑制放諏操作的隔离阀吗?

如果有,请指定操作人员祺进行监视如果没有,记录无

74

IstlereastaidadcoeratingpoceCurefordifcbVcesinplace?

现场有泄放设备的标准操作规程吗?

・ForFiQdVeification

-现场确认

75

Isligtirgsifficiiet?

照明充足吗?

76

IsenergencyligitirgsUficiet?

应急照明充足吗?

77

Aresteamp®

s,valves,otiapssitatedwithrnpoxmityofpjcpleirsU^ec?

位于人接近范围内的蒸汽管线、阀门或疏水器被隔离了吗?

78

Isaintumentaioiidsntifieandtagged?

所有的仪表都有标识和挂牌T吗?

79

Istlereanyrjstedordamagedequipment?

有任何生锈或损坏的设备吗

80

Areswinggatesiistaleloncflaid^rsor

onaccessplafoms?

在梯子顶部或平台通道上安装了止回门吗?

81

RevieweCgeprdectiolonpafomsandheights.Willitprotectprsanndadeqjipnent?

lsaccessadequate?

检査平台和高处的边缘保护它能保护人员和设备吗?

通道足够

82

Dosfetyshowerspro/ideahazardtopeopeslips)productCcntaminSticncfsytems)Ringresstoelectrc"

switchgearoreqjipmert?

安全喷淋对人滑跤的危险)产品(系统的污染)或内部的电气开关柜或设爵生危险了吗?

83

Aresfetyshowerssippliedfomtempenedwate?

安全淋浴供应热水吗?

84

Isclemcaldosingwithinasfeproximitycfp^opeaidproduct?

化学品操作是在人和产品安b接近范围内吗?

85

Labelalppelins标识所有的管线

86

Labelalesctrcswtcles,dscoinects,MCCs,cantiolpanels,cales,ec.

标记所有的电气开关、中断器、电动机控制器、控制盘和电缆

87

Label(materal,lazardwarnings)

List:

标记容器(材料、儘警告)的清单

88

Sealwillpnetatians密封墙壁的渗透

89

Pourconduitsis灌注导管的密封

90

Instil他eXingishers

91

Evacuationoutesposted

92

Instilapopra:

eareasigns

93

Isassffdriingandequipmentemoved;

issgier"

housekeepingaccetabe?

94

Ifthereisptentiafoertiapment(De^posireihasanEStopbeenprovided?

95

Iffillgarcingisiqdace,hasaloc<

dbleis<

l£

ltiandevicebeenpovided?

96

Pestc(rtlplequiiedinpam/buildng?

97

HSDSsleetsequre?

98

Sprirklersinpams?

99

Singlepoirtofauecp^Citip?

Hasitbenidsntifid?

-Record・

PSSRChecklistExampleA-2

PrestartjpSaetyReviewChecklist

InspectionDate:

DeohtmentArea

PropctNumbar:

Tite/Equipmeit:

Sigpetuiesbelowindcaeaccedtaxethatthsequipmentarpojectissfeandsatisfatcrytostart-upwiththeexceptionsnded・

Engineering/Mantenance

EHSGroup

QAGroup

Manufacturing/Operations

ProjectEngheer

ProcessEnginering

ChecklistItem

Details(referencecstegory/iemno.)

Responsbility

Complete

Sign&

CategoryAACianItms-ternstobecompletedBEFOREauthDrzatiorEndstat-up

1.

CategoryBACionItms-ternstobecompletedAFTEFStdt-p

5.

Signbdowonlywhenallpunchlisttefoesta-jpz/itensarecompeted

AUthorizei:

Faci1ityEqjipmertOwnerSigatire:

Date

PSSRTMNO.

CATEG0RY7ITEMTOASSESS

Not

Applicable

1.1

GENERALSAFEY

1.1.1

HaveALLappopratepesonnel((peiatians,Mairterance,T^hnical,adSipeVsio)receivedadequateandappropriatetairingontleequipmentandoperd:

irgprocedures?

1.1.2

Hasalequd:

eandap)raorid:

ePPE(PersonalPotectieEqjipment)beenspeci