Validation protocol for radiationWord格式.docx

《Validation protocol for radiationWord格式.docx》由会员分享,可在线阅读,更多相关《Validation protocol for radiationWord格式.docx(21页珍藏版)》请在冰豆网上搜索。

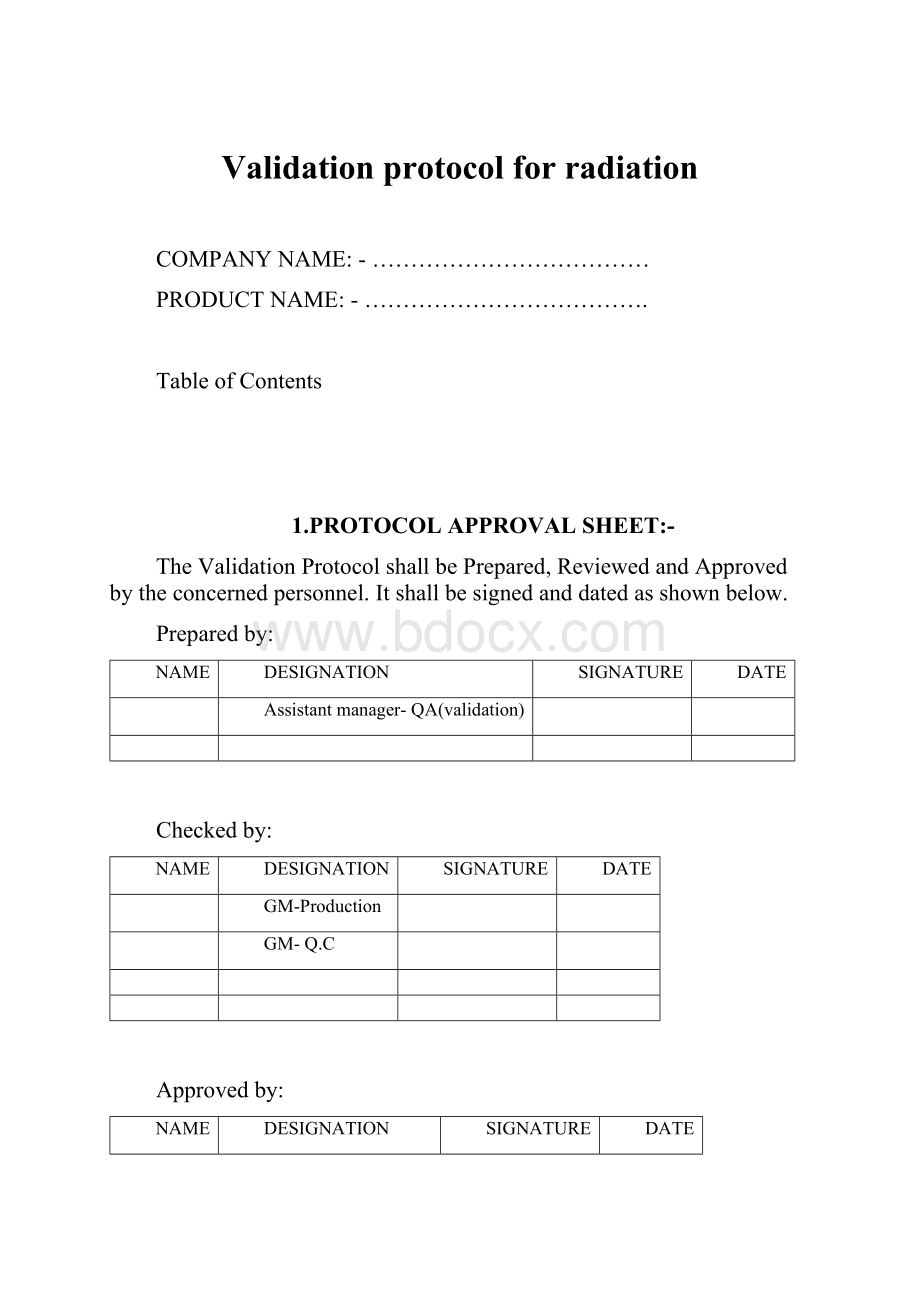

DATE

Assistantmanager-QA(validation)

Checkedby:

GM-Production

GM-Q.C

Approvedby:

GM-Qualityassurance

2.REVISIONHISTORY:

REVISION

REVISIONDATE

REASONFORREVISION/CHANGEREQUEST

REVISEDBY

01

11/06/2010

Originalrelease

3.OBJECTIVE:

Todeterminethatradiationsterilisationprocessconsistentlyperformsasintendedbyrunningthesystemonitsintendedschedulesandrecordingallrelevantinformationanddataandtestresultsmustdemonstratethattheprocessmeetspre-determinedspecificationsundernormalconditions,andwhereappropriateworstcaseconditions.

4.SCOPE:

-

Thescopeofvalidationprotocolistoprovidesterilizationvalidationstrategiesofradiationofmedicaldevice.Thisdocumentwillshowtwoapproachesforreducingoreliminatingbioburdenonmedicaldevices.Thiswillalsoshowtestmethod,samplingmethodandacceptancecriteriausedinvalidatingradiationsterilisationofmedicaldevices.

5.RESPONSIBILITY:

PERSON

RESPONSIBILITY

Validationteam

Ø

Preparationofprotocol

Organizationofvalidationactivity

CollectingthesamplesandsendingtoQC

Reviewandinterpretationoffinalresults

Preparationofreport

Qualitycontrol

Reviewofprotocolandreport

Analyzingthetestsamples

Reportingandinterpretationofresults

Production

Conductingthevalidationactivityaspertheprotocol

Qualityassurancemanager

Reviewandapprovethevalidationprotocol

6.STANDARDSFORREGULATORYREQUIREMENT:

∙ISO11137:

2006Sterilizationofhealthcareproducts—RadiationPart1:

Requirementsfordevelopment,validationandroutinecontrolofasterilizationprocessformedicaldevices

2006Sterilizationofhealthcareproducts—RadiationPart2:

Establishingthesterilization

2006Sterilizationofhealthcareproducts—RadiationPart3:

Guidanceondosimetricaspectsdose

∙ISO11737-1,Sterilizationofmedicaldevices—Microbiologicalmethods—Part1:

Determinationofapopulationofmicroorganismsonproducts

∙ISO11737-2,Sterilizationofmedicaldevices—Microbiologicalmethods—Part2:

Testsofsterilityperformedinthevalidationofasterilizationprocess

∙ISO10993-1:

2002BiologicalevaluationofmedicaldevicesPart1:

Evaluationandtesting

7.LISTOFSOPs:

∙SOPfore-beamsterilizationprocess

∙SOPforgammasterilizationprocess

∙SOPforenvironmentalmonitoring

∙SOPforsamplingprocedure

∙SOPfortestingmethod

∙SOPformaterialhandlingincludingbiologicalindicator

8.PREREQUISITE:

Thefollowingrequisitemustbefulfilledbeforetheradiationsterilizationprocessvalidation.

EquipmentQualification:

Equipmentassociatedwithradiationsterilizationprocessmustbequalifiedpriortoprocessqualification.

Calibration:

-

Allprocesssensing,controlling,indicating,andrecordingdevicesonthesterilizerorindependentsystemsassociatedwithsterilizermustbecalibratedandrecoded.Calibrationprogrammustbedocumentedanddetailedprocedureofcalibrationfrequencyforalltheinstrumentsshouldbeidentified.

Productandpackagingmaterialevaluation:

-

AsperAAMITIR17productandpackagingmaterialmustbeevaluatedfortensilestrength,impactstrength,andshearstrengthandpackagingintegrity.

Productgrouping:

Forefficientandcost-effectivevalidationperformance,similardevicescanbegroupedintofamilies.Productfamiliesforradiationprocessesshouldbeselectedbasedonbioburden.

Familyofproductsmustbeofsimilardesignandmaterialsofconstruction,andsimilarbioburdenlevels,butcanbeofdifferentsizes.

Selectionoffamilyrepresentative:

Eachfamilyofproductswillcontainanumberofdevices.Fromthesedevices,therepresentativechallengeproductisselected.Theselecteddevicewillbethemostdifficultdevicetosterilizeinthefamilygroupandwillbeusedinverificationdoseexperiments.Familyrepresentativeshouldbeselectedbasedonfollowingcriteria:

∙numberofmicroorganisms

∙typesofmicroorganisms

∙sizeofproduct

∙numberofcomponents

∙complexityofproduct

∙degreeofautomationduringmanufacture(manuallyassembled

∙productswillgenerallyhavehigherbioburdenlevels)manufacturingenvironment

9.PROCESSANDVALIDATIONAPPROACH:

E-beamSterilisationProcess:

Theproductisqualifiedfore-beamsterilisationforproductandpackagingintegrity,strengthandproductcharacteristics.Theproductisloadedonconveyorbeltaccordingtopre-establishedloadingpattern,consideringthenumberoftote,toteloadingandpackagingloadwrappingforshipment.Electronsaregeneratedbyelectronaccelerators.Acceleratorismachinewhichcontainfivecomponentssuchas,

Electrongun

Highvoltagefield

Vacuumtube

Electromagnet

Scamhorn

Acceleratoruseselectricalenergytogeneratefreeelectrons,acceleratethemtohighspeedandthendirectthemthroughaccelerator,atmaterialpassingonaconveyor.

GammaSterilisationProcess:

ThesterilisationprocessbyGammaRadiationinvolvesexposingtheproducttoradioactivesourcewhichemitsirradiation.GammaRadiationkillsmicroorganismsbyattackingtheDNAmolecule.BothdirectandindirectmechanismsareinstrumentalinthedisruptionoftheDNAbond,whichresultsinthepreventionofcellulardivisionand,consequently,thepropagationoflife.

Gammarayshavelowdoseratebuthighpenetrationpowerupto50cm.

TherearetwotypesofsterilisationprocessbyGammaRadiation,

1.CONTINUOUSPROCESS:

-workswithanautomatedconveyancesystemmovingproductthroughthemaze.

2.BATCHPROCESS:

-worksbyloadingasetnumberofcarriersandpositioninginirradiationchamber.

E-beamsterilisationprocessandparameters:

Sterilisationprocessstepsprocessparameterstobeconsider

Product

Bioburdenlevel

Productcompatibility

Productcharacteristics(density,geometry)

Productfamily/grouping

Electronspassthroughproductload

Electrongeneratedbyelectronaccelerators

Productloadingonconveyorbelt

Gammasterilisationprocessandparameters:

Productloadinginradiationchamber

SterilisationprocessstepsProcessparameterstobeconsider

GAMMARADIATION

Validationofradiationsterilization:

Radiationsterilisationvalidationcanbedonebyfollowingsteps.

1)Processqualification

2)Productandpackagingqualification

3)Administrativeproceduretoreviewandapprovedocumentation

4)Maintenanceofvalidation

1)Processqualification:

vDeterminationofproductloadingpattern:

–

Loadingpatternmustbespecifiedincludingnumberoftotes,toteloading,packaging,loadwrappingforshipment,minimumsterilisationdosefortheparticularloadingpatternandlocationofdosimeters.

vBio-burdendetermination:

Bioburdenisthepopulationofviablemicroorganismsonarawmaterial,acomponentofafinisheddevice.Theassessmentofthebioburdenincludesthenumberofmicroorganismswiththeiridentities.Dosesettingandproductgroupingisbasedonbioburdenlevel.

Obtainsamplesrandomlyfromthreedifferentbatchesofroutineproductionprocesses.

Bioburdenevaluationmustbeperformed

Performbioburdendeterminationbyextractingeachdeviceindividuallyandfilteringtheextractthroughasterilebacterialretentivefilter.

Performbioburdenrecoveryvalidation(Anadditionalnonsterilesamplesarerequiredforthis.)

Determinetheaveragebioburdenperdeviceforeachlot,aswellastheoverallbatchaveragebioburden

Calculatetheoverallaveragebioburden.Ifaspike(asinglevalueatleast2Xtheoverallaverage)occurs,thespikevaluemaybeusedratherthantheaverageforthedoseselection.

vDeterminetheVerificationDose:

Doseverificationcanbedonebymethod1,method2orVDmaxmethod.Refertotheappendix1fordescriptionofthismethod.

Ifanysinglebatchaverageis2timesgreaterthantheoverallbioburdenaverage,useittodeterminetheverificationdose.Ifnot,usetheoverallaverage.

Randomlyselectpackageddevicesfromasinglebatchofproducts.Thesecanbeselectedfromanyofthebatchesusedforbioburdenorfromafourthbatchrecentlymanufacturedinasimilarmanner.

Sterilitytestingmustbeperformedonthesterilisedsamples.Bacteriostasisandfungistasistestingmustbeperformedonthisproduct.

vEvaluationofsterilitytestresults:

Theverificationdoseisacceptableiftwo

(2)orlesssamplesshowgrowth.Ifmorethantwo

(2)samplesshowgrowth,theverificationtestisrejected.Aninvestigationshallbeperformedtoevaluateifthefailurecouldbeduetoincorrecthandlingofproduct,incorrectperformanceofthetest,orincorrectdosing.Ifsodetermined,theverificationdoseexperimentcanberepeated.

vSterilisationdoseselection:

Iftheverificationdoseisfoundacceptable,thenasterilizationdoseisdetermined.

vProductdosemapping:

Dosemappingofproductinanestablishedloadingpatternshouldbeconductedtodeterminetheminimumandmaximumdosezonesanddoseuniformity.

Prepareeachproductsamplesandplaceinfinalpackaging.

Sendthesamplesforproductfunctionality,packageandshippingevaluation.Theeffectofshippingandhandlingonthepackageshallbeevaluatedusingap