北美压铸压铸件公差标准NADCA Standard BriefWord格式文档下载.docx

《北美压铸压铸件公差标准NADCA Standard BriefWord格式文档下载.docx》由会员分享,可在线阅读,更多相关《北美压铸压铸件公差标准NADCA Standard BriefWord格式文档下载.docx(9页珍藏版)》请在冰豆网上搜索。

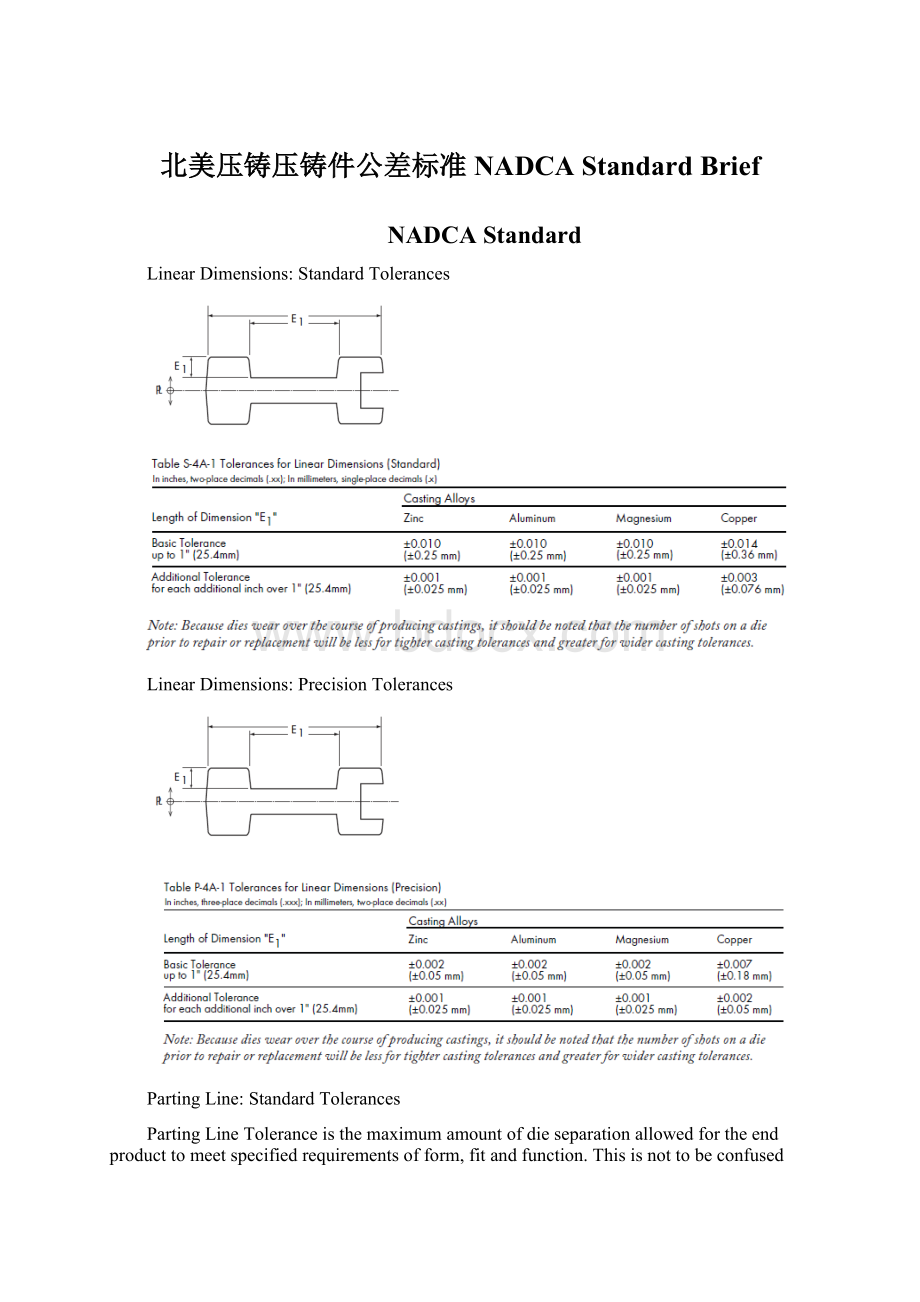

Thetotalpartthicknessincludingbothdiehalvesis5.00in.(127mm)whichismeasuredperpendiculartothepartingdieplane(dimension“E2E1”).FromtableS-4A-1,theLinearToleranceis±

0.010forthefirstinchand±

0.001foreachofthefouradditionalinches.TheLinearToleranceof±

0.014inchesiscombinedwiththeProjectedAreaToleranceof+0.012toyieldaStandardPartingLineToleranceof+0.026/-0.014in.orinmetricterms±

0.35mmfromLinearTolerancetableS-4A-1plus+0.30mmfromProjectedAreaTolerancetableS-4A-2=+0.65/-0.35mm.

PartingLineShift:

StandardTolerance

PartingLineShiftTolerance

Thecavityareaatthepartinglineis75inchessquared.FromTableS-4A-6,theProjectedAreaPartingLineShiftToleranceis±

0.006(±

0,152mm).ThisisaddedtotheLinearTolerancefromtableS/P-4A-1.

DraftRequirements:

Inthecaseofaninsidesurfaceforanaluminumcastpart,forwhichtheconstant“C”is30(6mm),therecommendedStandardDraftatthreedepthsis:

CoredHolesforCutThreads:

Coredholesforcutthreadsarecastholesthatrequirethreadstobecut(tapped)intothemetal.Thetablebelowprovidesthedimensionaltolerancesfordiameter,depthanddraftforeachspecifiedthreadtype(UnifiedandMetricSeries).Whenrequired,coredholesinAl,Mg,ZnandZAmaybetappedwithoutremovingdraft.ThisStandardTolerancerecommendationisbasedonallowing85%offullthreaddepthatthebottomD2(smallend)ofthecoredholeand55%atthetopD1(largeend)ofthecoredhole.Acountersinkorradiusisalsorecommendedatthetopofthecoredhole.Thisprovidesreliefforanydisplacedmaterialandcanalsoservetostrengthenthecore.

ThreadsextendthroughthecoredholeasbyY.Xshowstheactualholedepth.Aswiththecountersinkatthetopofthehole,theextraholelengthprovidesrelieffordisplacedmaterialandallowsforfullthreadengagement.Tolerancesbelowapplytoallalloys.

TableS-4A-9:

CoredHolesforCutThreads(StandardTolerances)–UnifiedSeriesandMetricSeries

AdditionalConsiderationsforLargeCastings

1FilletRadii:

1.1:

Definition:

Wallthicknessisthedistancebetweentwoparallelornearlyparallelsurfaces.Wallthicknessmayvarydependingontheapplicationofdraft.Wallthicknessshouldbemaintainedasuniformaspossible.Ageneralguidelinewouldbetokeeptherangeofthicknesswithin2Xofthethinnestwall.Asecondguidelineistokeepthewallasthinaspossibletomeetthecastingsfunctionalrequirements.

1.2:

General:

0.14”(3.5mm(+/-0.5mm)1.2.1Deviations:

fromthenominalconditionarebaseduponproductfunctionandmanufacturingprocessrequirements.

2Radii:

2.1FilletRadii:

2.1.1General:

0.14”(+0.08/-0.04”)[3.5mm(+2.0mm/-1.0mm)]

2.1.1.1Deviations:

2.1.2Minimum:

0.060”(1.5mm)

2.2CornerRadii:

2.2.1General:

0.060”(+0.08/-0.04”)[1.5mm(+2mm/-1mm)]

2.2.1.1Deviations:

2.2.2Minimum:

0.020”(0.5mm)

3Cores:

3.1Guidelines:

Coresshouldbeusedtominimizemachiningstock,andshouldbepulledperpendiculartoeachother.Usesteppedcoreswherepossibletominimizefinishstock,reduceheavysections,andminimizeporosity.

3.2Minimum:

Coredholediametertobe0.25”(6.0mm)inandparalleltothedirectionofdiedraw.

3.3ForholesLessThan:

0.50”(12.5mm)diameterthecoreholelengthtodiameter(L/D)ratioshouldnotexceed4:

1.

3.4ForHolesGreaterThan:

0.50”(12.5mm)diameterthecorepinlengthtodiameter(L/D)ratioshouldnotexceed10:

1

EjectorPinBosses:

SurfaceGeometry:

6.2.1:

0.06”(1.5mm)raisedto0.03”(0.8mm)depressed.

7Trimming&

Cleaning:

7.1PartingLines:

7.1.1TrimRibs-GateandPartingLine:

0.12”maximum(1.5mm)7.1.2Gates&

Overflows:

0-0.059”(0-1.5mm)7.1.3Flash:

Asspecifiedinnormalstandard.

7.2CoredHoles:

0-0.02”(0-0.5mm)

7.3Openings:

7.3.1:

0-0.06”(0-1.5mm)atthefinishmachinedface7.3.2:

0-0.03”(0-0.8mm)onas-castsurfaces7.3.3:

0-0.01”(0-2.5mm)ofcornerradii

7.4Corners-Sharp:

Notremoved.

7.5EjectorPinFlash(Max.Projection):

7.5.1:

0-0.12”(0-3.0mm)onmachinedsurfaces.7.5.2:

0-0.04”(0-1.0mm)onas-castsurfaces.

7.6MachinedSurfaces:

0.12”(0-0.3mm)max.

7.7SeamLines:

7.8Negativetrim(shearing):

conditionisallowedwhenthenominalwallthicknessismaintained.

Engineering&

Design:

AdditionalSpecificationGuidelines

AcceptableEjectorPinMarks

Ejectorpinmarksonmostdiecastingsmayberaisedordepressed.015”(.381mm).Raisedejectorpinmarksarepreferredforoptimumproduction.Largercastingsmayrequireadditionalejectorpintolerancesforpropercastingejection.

EjectorPinFlash

Ejectorpinmarksaresurroundedbyaflashofmetal.Normally,ejectorpinflashwillnotberemoved,unlessitisobjectionabletotheenduseofthepart.

Alternatively,ejectorpinflashmaybespecifiedascrushedorflattened.

Inthecaseofeithernonremovalorcrushing/flattening,flashmayflakeoffinuse.

Completeremovalofejectorpinmarksandflashbymachiningorhandscrapingoperationsshouldbespecifiedonlywhenrequirementsjustifytheaddedexpense.

Witheachdiecastingcycle,thedieopensandtheejectorplateintheejectorhalfofthedie(Fig.A)automaticallymovesallejectorpinsforward(Fig.B),releasingthecastingfromthedie.Then,thediecastingisremovedfromthediemanuallyormechanically.

5MetalExtension(Flash)Removal

GuidelinestoExtentofRemoval

Thetablebelowprovidesaguidetothetypesofdiecastingmetalextension(flash)whichoccursintypicaldiecastingsandtheamountofmetalextensionmaterialwhichremainsafter

(1)degating(removalofanygatesandrunnersfromthecasting),and

(2)commercialtrimmingofdiecastingmetalextension.

Notethatinsomeinstances,wherespecialsurfacefinishcharacteristicsarenotinvolved,themosteconomicmethodofdegatingandmetalextension(flash)removalmayincludeatumblingorvibratorydeburringoperation.

SurfaceFinish,As-Cast

GeneralGuidelinesforAsCastSurfaceFinishonDieCastParts

Thespecificationofexternalsurfacefinishrequirementsisdesirableforselecteddiecastingapplicationsand,inthecaseofsomedecorativeparts,essential.

Thepurposeoftheguidelinespresentedhereistoclassifyas-castsurfacefinishfordiecastingsintoaseriesofgradessothatthetypeofas-castfinishrequiredmaybeaddressedanddefinedinadvanceofdiedesign.

Theseguidelinesshouldbeusedforgeneraltypeclassificationonly,withfinalsurfacefinishqualityrequirementsspecificallyagreeduponbetweenthediecasterandthecustomer.

Thefirstfourclasseslistedrelatetocosmeticsurfaces.Classfiverelatestoselectedsurfaceareaswherespecifiedsurfacefinishlimitationsarerequired.

7DieCastLetteringandOrnamentation

Lettering,medallions,logotypes,trademarksandarangeofidentificationsymbolsmaybereproducedonthesurfacesofdiecastparts.

Suchas-castornamentationmayberaisedordepressed,butnotethatraisedletteringwillresultinlowerdieconstructioncostsandreduceddiemaintenanceoverthelifeofthedie.

Raisedletteringonadepressedpanelcanbeaneconomicalsubstitutefordepressedletters,asshownintheillustrationbelow.

Cast-inLettering/OrnamentationGuidelines

Inadditiontotheavoidanceofdepressedletteringorsymbolsinthecastingsurface,thefollowingguidelineswillachievethemostsatisfactoryresults.Thetermsusedrefertotheillustrationsbelow.

1.TheLineThickness(or“face”)ofanylettertobeclearlycastshouldbe0.010in.(0.254mm)orgreater.

2.TheHeight(orraiseddimension)ofacastletterorsymbolshouldbeequaltoorlessthanthelinethickness.

3.TheDraftAngleshouldbegreaterthan10°

.

4.Lettersorsymbolscontainingfineserifsordelicatelinescannotbeexpectedtodiecastcleanly.