BRC食品标准第六版中文版本中文翻译参考.docx

《BRC食品标准第六版中文版本中文翻译参考.docx》由会员分享,可在线阅读,更多相关《BRC食品标准第六版中文版本中文翻译参考.docx(33页珍藏版)》请在冰豆网上搜索。

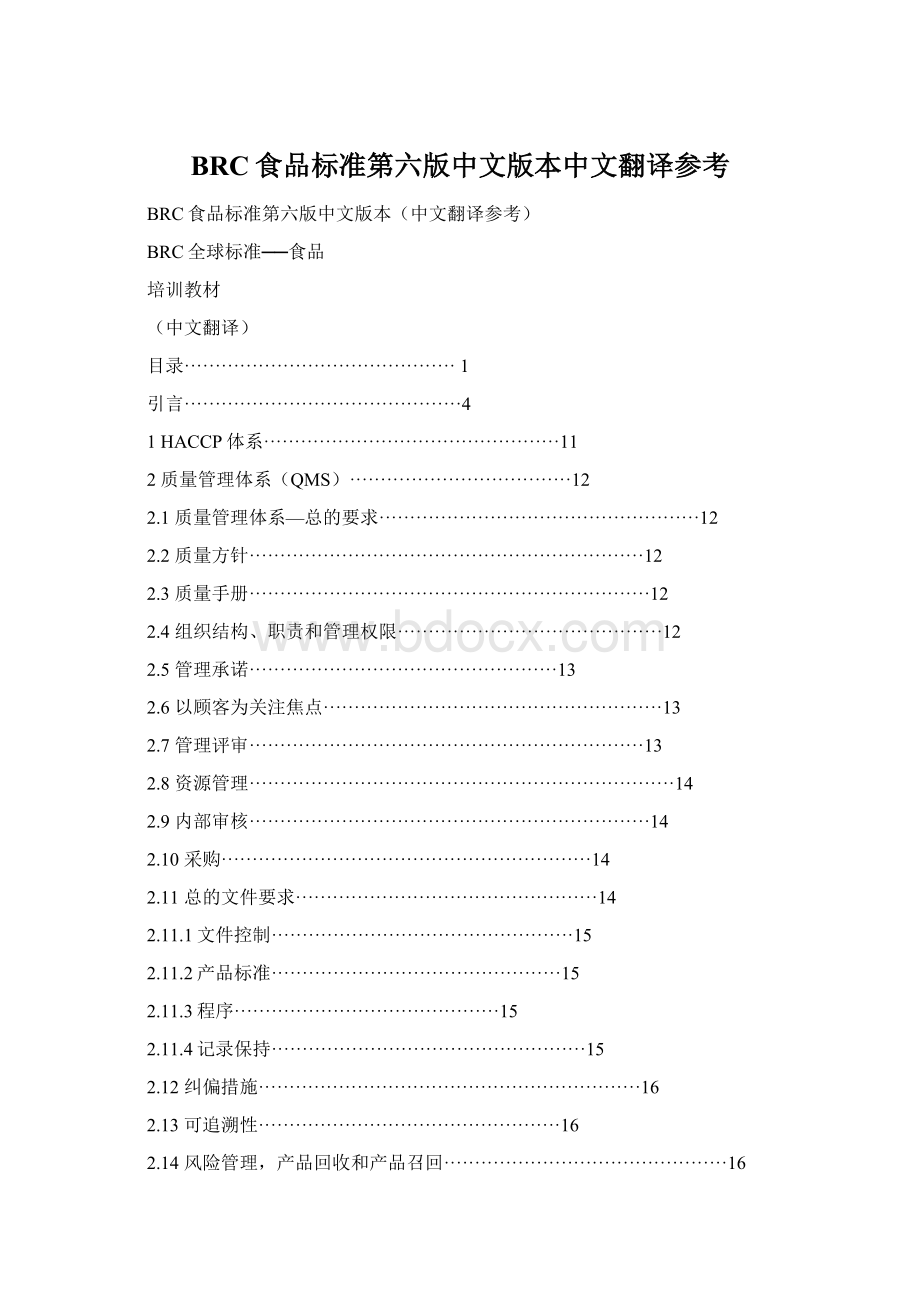

BRC食品标准第六版中文版本中文翻译参考

BRC食品标准第六版中文版本(中文翻译参考)

BRC全球标准──食品

培训教材

(中文翻译)

目录············································1

引言·············································4

1HACCP体系················································11

2质量管理体系(QMS)····································12

2.1质量管理体系—总的要求····················································12

2.2质量方针································································12

2.3质量手册·································································12

2.4组织结构、职责和管理权限···········································12

2.5管理承诺··················································13

2.6以顾客为关注焦点·······················································13

2.7管理评审································································13

2.8资源管理·····································································14

2.9内部审核·································································14

2.10采购····························································14

2.11总的文件要求·················································14

2.11.1文件控制·················································15

2.11.2产品标准···············································15

2.11.3程序···········································15

2.11.4记录保持···················································15

2.12纠偏措施······························································16

2.13可追溯性·················································16

2.14风险管理,产品回收和产品召回··············································16

2.15客户投诉的处理··················································17

3工厂环境标准·································································17

3.1外部环境标准··························································17

3.1.1选址························································17

3.1.2厂房和场地·····················································17

3.2内部环境标准················································17

3.2.1布局/生产流程/区域分隔···········································17

3.2.2设施结构──原料接收,准备,加工,包装和存贮区域·······························17

3.2.2.1墙面························································18

3.2.2.2地面······················································18

3.2.2.3天花板及顶部装置·················································18

3.2.2.4窗户·····················································19

3.2.2.5门·····································································19

3.2.2.6照明····························································19

3.2.2.7空气调节/通风系统·············································19

3.3设施····································································19

3.4设备······················································20

3.5维护保养····························································20

3.6员工设施····························································20

3.7产品的物理性及化学性污染的风险····································21

3.8设施管理和卫生·····················································21

3.9废弃物及废弃物处理·················································21

3.10害虫控制····································································22

3.11运输·································································22

4产品控制·············································23

4.1产品设计与开发·····················································23

4.2特殊处理的要求···········································23

4.3金属探测与异物探测··············································23

4.4产品包装························································24

4.5成品的检测及分析·············································24

4.6库存、周转·········································25

4.7产品放行····················································25

4.8不合格品的控制············································25

5生产过程控制·······················································25

5.1操作控制·················································25

5.2设备和加工确认··········································26

5.3测量及监控设备的的校准和控制·······························26

6人员···················································27

6.1培训──原料接收,准备,加工,包装和贮存区域··························27

6.2个人卫生──原料接收,准备,加工,包装和贮存区域···························27

6.3健康审查··················································28

6.4工作服──食品操作人员及其他食品加工区域的工作人员或参观人员················28

7专业术语··································································28

引言

|背景

根据“1990年英国食品安全法案”规定,与涉及到食品供应的所有部门相同,零售商有责任采取一切合理的预防措施,并克尽职责,避免在研发、制造、配送、广告宣传或销售食品的过程中出现的任何偏差。

零售商对其自有品牌食品的责任包括很多方面,在食品加工场地的技术表现的审核就是其中之一。

长期以来,每个英国零售商根据自己制定的内部标准,独自对食品的加工场地进行审核。

大多数审核工作由零售商内部的技术人员执行,其他则交由独立的检验机构执行。

1998年,英国零售商协会(BritishRetailConsortium/BRC)编写并引入“针对零售商自有品牌食品的供应商的BRC技术标准和规程”(BRC食品技术标准)。

本标准最初是用于零售商自有品牌食品的供货标准,但近年来BRC食品技术标准被广泛地应用到食品工业的其他部门,例如:

食品服务业和食品配料的生产。

有很多具体事例表明BRC食品技术标准不仅在英国本土之外被采用,

而且已经成为一些公司编写供应商评估程序的基础架构。

“BRC食品技术标准”首版于1998年发行,现已进行了三次修订。

“标准”的第四版已于20XX年发行。

每次的审议和修订,英国零售商协会都会广泛地征求建议,以确保可接受性和公正性,更重要的是促进形成最有操作性的标准。

20XX年1月,为了反映“BRC食品技术标准”在使用过程中的一些变更,英国零售商协会认

识到其名称和范围需要改变,并更名为“BRC全球标准──食品”。

BRC相信通过这种变更,能确保