w2cavityradiationia文档格式.docx

《w2cavityradiationia文档格式.docx》由会员分享,可在线阅读,更多相关《w2cavityradiationia文档格式.docx(12页珍藏版)》请在冰豆网上搜索。

∙Definecavityradiationproperties.

∙Plotandanimatecontoursofthetemperaturedistribution,andplotthetemperaturehistoryofselectedpointsinthefin.

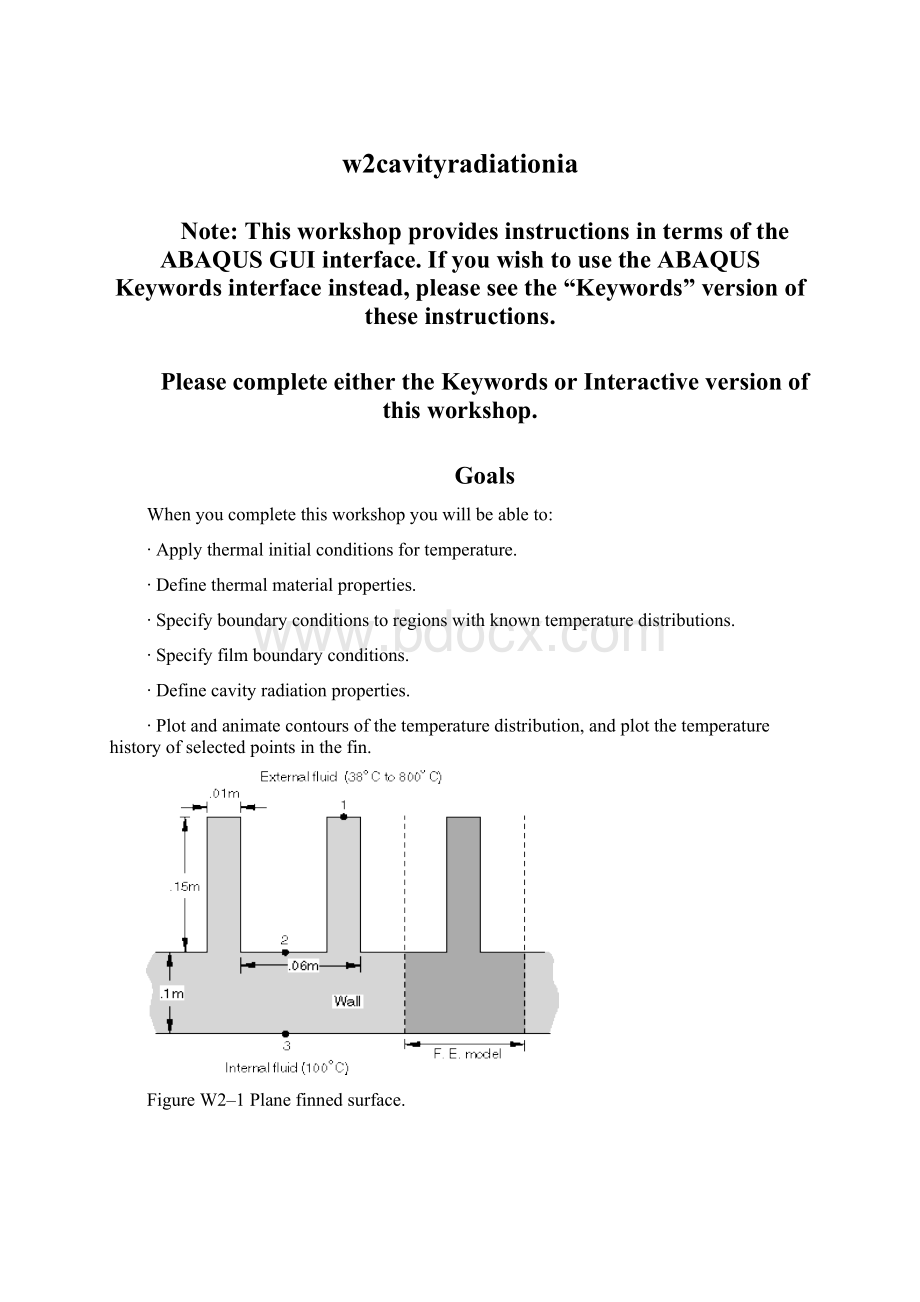

FigureW2–1Planefinnedsurface.

Introduction

ThisworkshopillustratestheABAQUScapabilitytosolveheattransferproblemsincludingcavityradiation.Wesimulatetheeffectsofafireconditiononaplanefinnedsurface.TheconfigurationshowninFigure

W2–1representsaplanewallwithauniformarrayofparallelrectangularfinsattached.

Theproblemrepresentsthreephasesinafiretest:

∙Thefirstisthepretest,asteady-stateconditionwhereheatistransferredbynaturalconvectionfromaninternalfluidatafixedtemperatureof100°

Ctotheplaneinsidewall.Heatisconductedthroughthewallanddissipatedbyradiationandnaturalconvectionfromtheoutsidewallandfinsurfacestothesurroundingmedium,whichisatatemperatureof38°

C.

∙Thesecondphaseisa30-minutefiretransient,whereheatissuppliedbyradiationandforcedconvectionfromahotexternalfluidat800°

C.Afterconductionthroughthefinsandwall,heatisrejectedbynaturalconvectiontotheinternalfluid.

∙Finally,thethirdphaseisa60-minutecooldownperiod,whereheatabsorbedduringthefiretransientisrejectedtothesurroundingsbythesameprocessasthatusedtoestablishtheinitialsteady-statecondition.

Theobjectiveofthisworkshopistodeterminethetemperaturedistributioninthewallandfin.WemakeuseoftheradiationperiodicsymmetrycapabilityinABAQUStorepresentthearrayoffinswhilemeshingonlyonefinandcorrespondingwallsection.Theoutsideambientismodeledwithasinglehorizontalrowofelementslocatedatadistanceabovethetopofthefin.

Preliminaries

1.Entertheworkingdirectoryforthisworkshop:

../heat_transfer/interactive/workshop2

Runthescriptws_ht_cavity.pyusingthefollowingcommand:

abaquscaestartup=ws_ht_cavity.py

TheabovecommandcreatesanABAQUS/CAEdatabasenamedcavity.caeinthecurrentdirectory.Themodelassemblyandsomenecessarysetandsurfacedefinitionsareprovided,asshowninFigure

W2–2.Themodelmesh,consistingof150two-dimensionalheattransferelements(DC2D4),hasalsobeenpredefined.Inthisworkshopyouwilladdthenecessarydatatocompletethemodel.

Outsideambient:

Setambient

Surfacebot

Surfacesrfs

Surfacesamb

FigureW2–2Predefinedsetsandsurfaces.

Materialpropertiesandphysicalconstants

Beginbydefiningthematerialpropertiesandphysicalconstantsforthismodel.

2.DefineamaterialnamedMSTRUCwiththefollowingproperties:

∙Thedensityis7800kg/m3.

∙Theconductivityis50W/m°

∙Thespecificheatis500J/kg°

3.CreateahomogeneoussolidsectionusingthematerialMSTRUC.

4.Assignthissectiontoboththeambientandfinparts.

5.Definethefollowingphysicalconstantsinthemodelattributeeditor(ModelTree:

double-clickCavityRad):

∙Thetemperatureofabsolutezerois-273°

∙TheStefan-Boltzmannradiationconstantis5.669710-8W/m2°

K4.

Analysishistorydefinition

Thedatarequiredtodefinetheanalysishistoryarethesteps,outputrequests,andboundaryconditions.TheheatflowthatwilloccurineachstepalongwiththeassociatedboundaryconditionsareillustratedinFigure

W2–3.

FigureW2–3Heatflowandstep-dependenceoftheboundaryconditions.

Stepdefinitionandoutputrequests

6.Createaheattransferstep.Setthestepresponsetypetosteadystate;

ABAQUSautomaticallychangesthedefaultloadvariationtoramploadslinearlyoverthestep.Acceptthedefaultvalueof1forboththetotaltimeperiodandtheinitialtimeincrementsize.

7.Createasecondheattransferstep.Accepttransientasthestepresponsetype.Specifyatotaltimeperiodof1800secondsandaninitialtimeincrementof10seconds.Setthemaximumallowabletemperaturechangeperincrementto100°

8.Createathirdandfinalheattransferstep.Accepttransientasthestepresponsetype.Specifyatotaltimeperiodof3600secondsandaninitialtimeincrementof10seconds.Setthemaximumallowabletemperaturechangeperincrementto100°

YoualsoneedtospecifytheappropriateoutputtobeabletocontourthetemperatureinthewallandfinsandtocreateX–Yplotsofthetemperaturehistoryofselectedpointsinthemodel.

MakeStep-1currentbyselectingitfromtheSteplistlocatedunderthetoolbar.ThisisnecessarysothatthefollowingoutputrequestmodificationswillbedefinedinStep-1andpropagatedthroughouttheanalysis.

9.Editthedefaultfieldoutputrequestsforthisstep,sothatonlyvariableNT,nodaltemperatures,willbewrittentotheoutputdatabasefileduringtheanalysis.

10.Deletethedefaulthistoryoutputrequest(ModelTree:

HistoryOutputRequests:

clickmousebutton3onH-Output-1:

Delete).

11.CreateahistoryoutputrequesttorecordnodaltemperaturesatthethreepointshighlightedinFigureW2–4.Thedetailedprocedureisgivenbelow.

a.IntheModelTree,expandtheAssemblyanddouble-clickSets.

b.NamethesetoutputandclickContinue.

c.Intheviewport,use[Shift]+clicktoselectthethreepointsshowninFigureW2–4.Then,clickDoneinthepromptarea.

d.IntheModelTree,double-clickHistoryOutputRequests.

e.AcceptH-Output-1astherequestnameandStep-1astherequestdefinitionstep.

f.IntheEditHistoryOutputRequestdialogbox,selectSetintheDomainfieldandselectoutputfromthelistofsetsthatappears.

g.Fromthelistofavailableoutputvariables,clickthearrownexttoThermaltoexpandthevariablelist.ToggleonNT,NodaltemperatureandclickOK.

Setoutput

FigureW2–4Locationsforhistoryoutput.

Filmconditions(forsurfaceconvection)

12.DefinetheStep-1filmconditions(i.e.,surfaceconvectionconditions)ontheinnerandoutersurfacesofthewall.Usetheappropriatevaluesforthesinktemperature(θf)andfilmcoefficient(h)showninFigure

W2–3.Surfacesbotandsrfs,representingtheinnerandoutersurfacesofthewall,respectively,havebeendefinedforyourconvenience.Detailedinstructionsareprovidedbelow:

a.IntheModelTree,double-clickInteractions.

b.Nametheinteractionbot,selectSurfacefilmconditionastheinteractiontype,andacceptStep-1asthedefinitionstep.

c.Whenyouarepromptedtoselectthesurface,clickSurfacesinthepromptarea.IntheRegionSelectiondialogbox,selectbotandclickContinue.

d.IntheEditInteractiondialogbox,enter2500asthefilmcoefficientand100asthesinktemperature.

e.Repeatthestepsabovetodefinethefilmconditionsrfsonthesurfacesrfswithafilmcoefficientof10andasinktemperatureof38.

13.Modifythefilmconditionappliedtotheoutersurfaceofthewallandfin(surfacesrfs)inStep-2usingtheappropriatevaluesforthesinktemperatureandheattransfercoefficientshowninFigure

a.IntheModelTree,clickmousebutton3onInteractionsandselectMangerinthemenuthatappears.

b.Inthemanger,selectthecelllabeledPropagatedintherowforthesrfsfilmconditionandthecolumnforStep-2.ClickEdit.

c.IntheEditInteractiondialogbox,changethesinktemperatureto800.

14.Modifythefilmconditionappliedtotheoutersurfaceofthewallandfin(surfacesrfs)inStep-3usingtheappropriatevaluesforthesinktemperatureandheattransfercoefficientshowninFigure

Boundaryconditions

15.ApplyatemperatureboundaryconditioninStep-1totheregionrepresentingtheoutsideambient(setambient).Setthetemperatureto38°

C.

16.ForStep-2modifythetemperatureprescribedtothesetambientto800°

C.(UsetheBoundaryConditionManager:

intheModelTree,clickmousebutton3onBCsandselectMangerinthemenuthatappears.)

17.ForStep-3changethetemperatureprescribedtothesetambientbackto38°

Initialconditions

Theinitialtemperatureofallcomponentsofthemodelis77°

1.Createatemperaturefieldintheinitialsteptoassignaninitialtemperatureof77tothesetall.

Cavitydefinitionandradiationsurfaceproperties

Thecavityinwhichradiationoccursiscomposedoftheoutsideofthewallandfinandtheoutsideambient.Todefinethecavity,youwillusetwopredefinedsurfaces,SRFSandSAMB,whichrepresenttheoutsideofthewallandfinandtheoutsideambient,respectively(seeFigureW2–2).Theemissivitiesofthewall,fin,andoutsideambientmustbespecified.Youmustalsodefinetheradiationviewfactorandtheappropriateradiationsymmetryconditionsforthecavity.CurrentlythesefeaturesarenotsupportedinABAQUS/CAE.Usethekeywordseditortodefinethecavityanditsrelatedproperties,asdescribedbelow:

1.IntheModelTree,clickmousebutton3onthemodelnamedcavityRadandselectEditKeywordsinthemenuthatappears.

2.IntheEditkeywords,Model:

cavityRaddialogbox,selectthe*InitialconditionsoptionblockandclickAddAftertwicetoaddtwoemptytextblocks.

3.Inthefirstnewtextblock,usethe*SURFACEPROPERTYoptiontocreateasurfacepropertynamedREFLforthewallandfins.Inthesecondone,usethe*EMISSIVITYsuboptiontodefineane