数控编程题文档格式.docx

《数控编程题文档格式.docx》由会员分享,可在线阅读,更多相关《数控编程题文档格式.docx(32页珍藏版)》请在冰豆网上搜索。

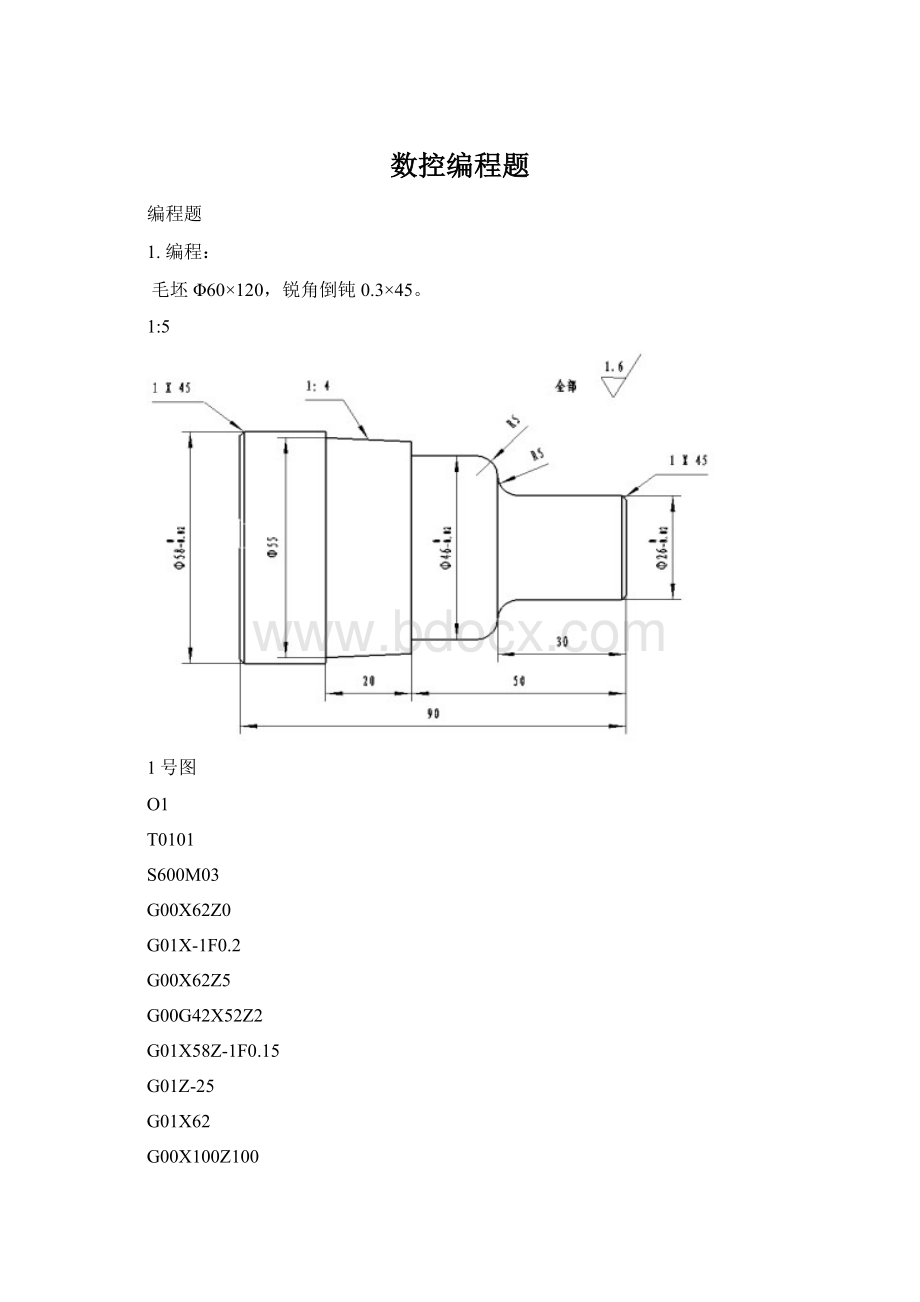

G02X46Z-30R10

G01Z-50

G01X51

3.

3号图

M03S800

M08

G00X47Z2

G71P1Q2U2F0.2

N1G00X0G42

G01Z0

G03X10Z-5R5

G01X20

G01W-10

G03X30W-5R5

G01X40W-12

G01W-18

N2G01X47G40

T0100

G70P1Q2G0.12

T0202

M03S400

G00X42Z-55

G75R0.3

G75X4Z-55P5000F0.1

G00X100

Z100

4.

G00X65Z2

N1G00X46.785G42

G01X50Z-6

G01X56

G01X58

G01X60Z-21

G01Z-40

N2G01X65G40

G00X62Z-35

G75R0.2

G75X4Z-35P5000F0.1

5.

M3S800

G73U32R16

G73P1Q2F0.2

N1G00X30G42

G01Z-10

G01X28W-3

G01W-4

G01X30W-3

G01W-12

G02X36W-3R3

G01X40

G01X60

G01Z-70

G01X65

N2G00Z2

M03S1100

G70P1Q2G0.1

G00X62Z-65

G75X4Z-65P5000F0.1

6.用数控车床加工如图所示零件,材料为45号钢调质处理,毛坯的直径为40mm,长度为200mm。

按要求完成零件的加工程序编制。

(1)粗加工程序使用固定循环指令;

(2)对所选用的刀具规格、切削用量等作简要工艺说明;

加工程序单要字迹工整

6.1

(1.刀具选择

外圆尖刀Kr=93度刀尖角35度粗车S600ap2f0.15

精车S1200ap1f0.12

切断刀刀宽5mmS600ap4f0.12

螺纹刀S500)

O1(WAIYUAN)

G00X42Z2

G73U10W0R5

G73P1Q2U2W0F0.15

N1GOOX16G42

G01X24Z-2

G01Z-15

G01X20Z-20

G01W-7

G02X38W-7R10

G01X38W-8

G01X20W-20

G01W-6

G01X34

G01W-15

G01X42

S1200M03

T0202(QIECAO)

G00X28Z-20

G01X16F0.12

G04X1

G00Z100

TO3O3(LUOWEN)

M03S500

G00X26Z5

G92X23Z-17F3

X22.2

X21.4

X20.9

X20.5

X20.3

X20.1

T0202(QIEDUAN)

G00X42Z-83

G01X30F0.2

G00X36

G00W2

G01X32W-2

G01X0

螺纹刀刀尖角60度S500)

TO1O1(WAIYUAN)

G7U12W0R6

N1G00G42X10

G01X16Z-1

G01X24

G03X24W-25R15

G01X38W-30

G01Z-100

TO1O1

TO2O2(QIECAO)

G00X8Z-25

G01X12F0.12

T0303(LUOWEN)

G00X20Z5

G92X15.2Z-23F2

X14.8

X14.5

X14.3

X14.1

X14

S500M03

G00X42Z-100

G0062Z2

G90X57Z-40F0.2

G00Z0

G01X-1

G00G42X49Z2

G01X55Z-1F0.12

G01X100Z100G40

G73U13W0R6

G73P1Q2W0F0.15

N1G00X26G42

G01X34Z-2

G01Z-30

G01X38

G01X50W-25

G01W-25

G02X50Z-119R35

G01W-20

G00X40Z-30

G01X30F0.12

T0303

G0X36Z5

G92X33.2Z-28F2

X32.8

X32.5

X32.2

X32

切断刀刀宽5mmS600f0.18

螺纹刀刀尖角60度S500f3)

G01X-1Z0F0.2

N1G00G42X16

G01Z-35

G01X27Z-52.5

G02X32Z-55R2.5

G01X45

G03X50W-2.5R2.5

S1000M03

G00X26Z-35

G92X23Z-33F3

6.5

G00X62Z8

G73U18W0R9

G73P1Q2U2W0F0.2

N1G00G42X24

G01X30Z-16

G02X34W-10R10

G01X34W-12

G02X40W-3R3

G01X50

G03X56W-3R3

G01Z-67

N2G00G40Z8

G00X38Z-20

G01X26

G00X32Z8

G92X29Z-18R-6.5F1.5

G92X28.7Z-18R-6.5F1.5

G92X28.55Z-18R-6.5F1.5

7.编制立式加工中心加工零件外轮廓、凸台轮廓的加工程序,填写工序卡、刀具使用卡

加工中心1

O0001

G21

G0G17G40G49G80G90

T1M6

G0G90G54X-69.75Y20.S600M3

G43H1Z50.

Z10.

G1Z-19.F15.

G42D1X-49.75F60

G2X-29.75Y0.R20.

G3X29.75R29.75

X-29.75R29.75

G2X-49.75Y-20.R20.

G1G40X-69.75

Z-9.F15.

G0Z50.

X61.5Y20.S600M3

G1Z-19.F100.

G41D1X41.5F60.

G3X21.5Y0.R20.

G1Y-19.5

G2X19.5Y-21.5R2.

G1X-19.5

G2X-21.5Y-19.5R2.

G1Y19.5

G2X-19.5Y21.5R2.

G1X19.5

G2X21.5Y19.5R2.

G1Y0.

G3X41.5Y-20.R20.

G1G40X61.5

G49

M5

T2M6

G54G00G90G49G40X0Y0

G43H2Z50

S640M03

G83X0Y0Q5R3Z-38

G80

G00Z150

M09

T3M6

G81X0Y0R3Z-38

%

加工中心5

M6T1

G54G40G49G00G90X60Y0

G43H1z50

S300M03

Z-20

G01G42D1X21.5F30

Y19.5

G03X19.5Y21.5R2

G01X-19.5

G03Y19.5R2

G01Y-19.5

G03x-19.5Y-21.5R2

G01X19.5

G03x21.5Y-19.5R2

G01Y0

G00G40X60

G00Z100

Z-12

G42G01X16.5D1F30

G03I-16.5

G00Y-30

G00Z-8

G01G41D1Y-12.5

G01X-60

G00Y12.5

G01X60

G00G40Y0

M6T2

G54G40G49G00G90X0Y0

S700M03

G98G81X0Y0R3Z-40F30

G98G81X15.5Y15.5R3Z-26F30

G98G81X-15.5Y15.5R3Z-26F30

G98G81X-15.5Y-15.5R3Z-26F30

G98G81X15.5Y-15.5R3Z-26F30

G00Z150

M6T3

G43H3Z50

S100M03

G0G90G54X80.Y60.S300M3

G1Z-32.F1000.

G41D1X60.F30.

G3X40.Y40.R20.

X-40.

Y80.

X40.

Y40.

G3X60.Y20.R20.

G1G40X80.

Z-22.F2000.

%O2

G0G90G54G49X66.Y60.S300M3

G1Z-10.F1000.

G41D1X46.F40.

G3X26.Y40.R20.

G1Y14.

X-26.

Y66.

X26.

G3X46.Y20.R20.

G1G40X66.

Z0.F2000.

T2M6

G0G90G54X37.Y32.5S600M3

G43H2Z50.

G42D2X31.F100.

G2X25.Y38.5R6.

G1Y54.

G3X7.R9.

G2X-7.R7.

G3X-25.R9.

G1Y23.

G3X-17.Y15.R8.

G1X17.

G3X25.Y23.R8.

G1Y38.5

G2X31.Y44.5R6.

G1G40X37.

T3M6

G0G90G54X-5.Y35.S800M3

G43H3Z50.

G1Z-8.F1.8

G41D3Y30.F95.4

G3X0.Y25.R5.

G1X11.

G3Y37.R6.

G1X-11.

G3Y25.R6.

G1X0.

G3X5.Y30.R5.

G1G40Y35.

Z2.F1.8

T4M6

G0G90G54X-29.Y11.S640M3

G43H4Z10.

G98G81Z-13.004R10.F30.

X29.

Y69.

X-24.

G0G90G54X51.5Y34.5S600M3

G43H1Z50.M8

G1Z-10.F200.

G41D1X39.5F40.

G3X27.5Y22.5R12.

X15.

Y8.

G3X8.Y15.R7.

G1X-8.

G3X-15.Y8.R7.

X-27.5

Y45.

X-17.5Y55.

X17.5

X27.5Y45.

Y22.5

G3X39.5Y10.5R12.

G1G40X51.5

G0G90G54X10.Y40S600M3

G43H2Z50.M8

G1Z-5.F30.

G01G41Y34D1

G3Y46.R6.

G1X-10.

G3Y34.R6.

G1X10.

G01G40Y40

Z5.F2000.

M9

G0G90G54X72.Y16.S300M3

G1Z-5.F100.

G41D1X52.F30.

G3X32.Y-4.R20.

G1Y-16.

X16.Y-32.

X-16.

X-32.Y-16.

G2X-8.Y32.R24.

G1X8.

G2X32.Y8.R24.

G1Y-4.

G3X52.Y-24.R20.

G1G40X72.

G0G90G54X0.Y-2.S600M3

G42D2X20.

G1Y-6.

G2X14.Y-12.R6.

G1X-14.

G2X-20.Y-6.R6.

G1Y2.

G2X-14.Y8.R6.

Y17.

G2X-4.Y23.R6.

G1X4.

G2X10.Y17.R6.

G1Y8.

X14.

G2X20.Y2.R6.

G1Y-2.

G01G40X0.

G00Z5.F2000.