手机品质检验规范英文版Word文件下载.docx

《手机品质检验规范英文版Word文件下载.docx》由会员分享,可在线阅读,更多相关《手机品质检验规范英文版Word文件下载.docx(41页珍藏版)》请在冰豆网上搜索。

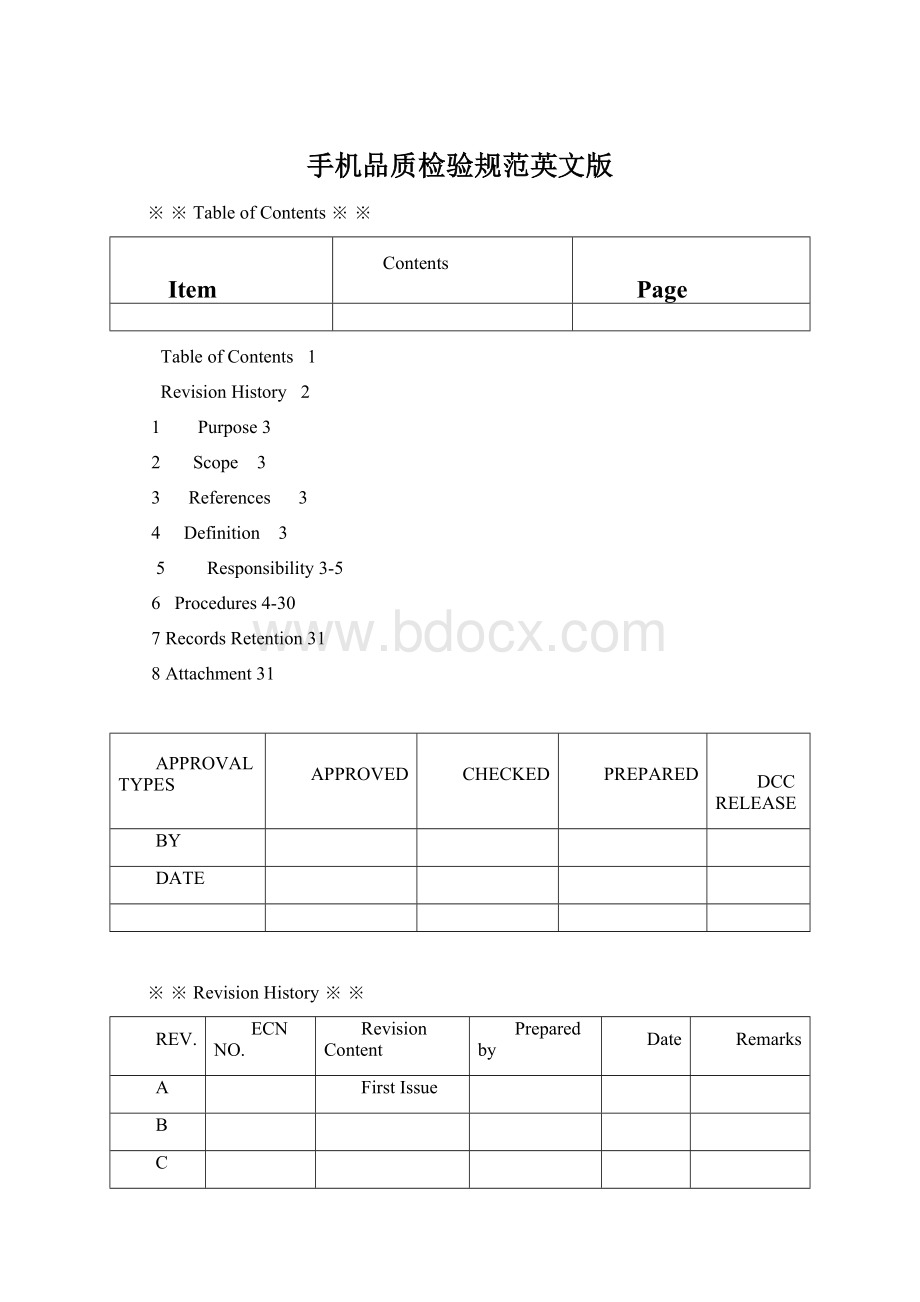

RevisionContent

Preparedby

Date

Remarks

A

FirstIssue

B

C

D

E

F

G

H

J

K

L

M

N

P

Q

R

S

T

U

V

W

Y

Z

1.Purpose

DefinecosmeticcriteriaofGioneemobilephoneproduct,DefinedefectdeterminingbaselineofGioneemobilephoneproductcosmeticinspection,letproducer,inspectorcanunderstandproductinspectioncriteriacorrectlyandquickly.Toensureproductquality,satisfycustomer’srequirement.

2.Application

ApplytocosmeticFunctioninspectionforGionee;

3.Inspectionrequirements

3.1Inspectionqualification:

Beforetheinspectorschecktheproducts,theywouldbeofferedon-the-jobtrainingandgotthecertificationoftheirinspectionskills.

3.2illuminationrequirement:

l.1000±

200Lux,preventinterferedbyotherilluminant.

3.3Inspectiondistance:

Forallthestandarddistance(fromoureyestoproducts)fromthesurface(anysurfacelevel)observationis30-35cm.

3.4Inspectionangle

Inspectionangle:

Testedsurfaceandthelineofsightwithin45degreesofrotation,inordertomakethepartstotestinallpossibleilluminationconditions,inspectorsshouldrotateinalldirectionsfromtheproductsothatalldefectsarevisible.

3.5Inspectionenvironment

Inordertoreduceinspectortodeterminethecolorerrorweneedtocreateanenvironmentthatisneutralcolor,sothecomponentsandassembliesshouldbeinfrontofagraybackground.

3.6Inspectioninstrument

Inspectorsneedtousepointgaugetodeterminetheflawsofappearance,thepictureofpointgaugeseechart:

3.7DefectDefinition

Seriousdefect:

Productdefectjeopardizeuserorproducer’slife&

security

Majordefect:

Defectreducesproductfunctionorusedeffect,cannotmeetexpectedobjective.

MinorDefect:

Defectdoesn’tinfluenceproductfunctionorusedeffect,justablemish.

3.8Samplingstandard

ThesamplingstandardshouldfollowMIL-STD-105EAQL=0.65II

1)20pcsmakeupaLot.

Normalinspection:

5outof20sampled.

Strictinspection:

8outof20sampled.

Reducedinspection:

3outof20sampled

2)Inthebeginning,usenormalinspectiongenerally

a.NormalinspectionStrictinspection:

Continuouscheck5batches,thereare2batchesrejected.

b.Continuous5batcheswhichwereallowedthenstopcheck.

c.Normalinspection---Reducedinspection:

Continuous10batcheswhichwasallowed.

3.9Returnsstandard

Cosmeticdefects:

FoundtheunqualifiedproductsthatexceedAQL,thenthecurrentbatchandbefore

&

afterthecurrentbatchwillberejected.Totalreturn3batches

Functiondefects:

FoundtheunqualifiedproductsthatexceedAQL,thenthecurrent2batchesandtheformer2batches&

afterthe2batcheswillberejected.Totalreturn5batches

ReturntoMFGandarrangeforsorting,theninformtheENGandQAtoanalysisandimprovement.

MIL-STD105E

Samplequantityindex

Batch

Specialinspectionlevel

Generalinspectionlevel

Range

S-1

S-2

S-3

S-4

Ⅰ

Ⅱ

Ⅲ

2--8

9--15

16--25

26--50

51--90

91--150

151--280

281--500

501--1200

1201--3200

3201--10000

10001--35000

35001--150000

150001--500000

500001--above

4.Definitionofproductdefects:

Color&

gloss:

Usethesignedstandardsampleorthecolorlimitsampleasthestandard

Spotdefect:

Takethelargestareaasthesizeofthespotdefect

Colormottle:

Thereisaspot,whichhascolordifferencefromtheotherareaofproduct.

Shrinkage:

Itishardtomaintainthehighmoldingpressuretoinjectionmoldingtheunevenproductthickness,whichwillcausethesinkmarkonthethickercrosssectionarea.

Weldline:

Duringtheinjectionmoldingprocess,theplasticflowencountersmanytoolstructuresandplasticflowcannotmeltandintegratewell,whichleavesanobviouslineonthesurfaceofplasticparts.

Cracking:

Theinternalstressorthedamageleadstothecrackingonplasticpartssurface.

OilStain:

Thereisoilmarkleftonplasticpartsurface.

Warp&

deformation:

Thestressortheunevenforceduringmoldingprocesswillcausethewarpand

Deformationofplasticpart.

Flash:

Duetoinjectionmoldingtechniqueorthetool,itmaycausetheflashonthepartingarea.

Scratchmark:

Thefrictionorscratchleadstospot,lineorflakedamage.

Bubble:

Iftheplasticpellethasbeenfullydriedbeforemolding,thewaterinthehigh-temperature

Plasticwillvaporizeandleastobubbleontheplasticpart.

Streak:

Therearegrowth-ringlinesaroundthegate.

Fatedge:

Thepaintisunevenandstacksuponcertainareaofpaintedpartsduetotheimproperleveling.

Orangepeel:

Thereisorangepeel-likewinkleonthepaintedpartsurface.

Particle:

Therearetinyparticlesonthepaintingpartsurface.

Fabric:

Therearesometinyfursonthepaintinglayer.

Colordifference:

Thepaintingcolorisdifferentfromthestandardcolorboardorgoldensample.

Glossdifference:

Theglossofpaintinglayerisbeyondglossdifferenceofthestandardsample.

Roughness:

Thepaintingsurfaceisunevenandrough.

Stain:

Thereisblemishorblotonthepaintingsurface.

5.SurfaceoftheproductGrade

Producthasfourlevels:

Front、Back、Flank、Inside.

Front:

Thefrontofvisualarea,includethedisplayareaofLCD,thefrontcameraarea、Sensation、touchkey

Back:

Thebackofvisualarea,includebatterycover、rearcamera、flashlightarea

Inside:

Openthebatterycover;

includethebackofthebatterycover&

insidethebatterycover,thebatterycompartment&

theantennaarea

Flank:

Thefourflankofphone,includethebutton&

USB&

headset&

speaker&

MIC

ClassC

ClassB

ClassA

6.Inspectionandjudgmentprinciple

6.1Colorandluster,accordingtothepartsofthecontractstandardsampleorcolorlimitsamples;

6.2Inspectorsmustteststrictlyonthebasisofstandard,andjudgethequalifiedofbatchesobjectively;

6.3Whenthenumberofallthedefectsgeneratedbytestingmorethantheacceptancenumberofallowabledefects,determinethewholebatchesofproductsunqualified.Ifthesameproductwasfoundtwokindsofdefectsatthesametime,discriminatedaccordingtoitsheaviestdefect.

6.4Whentheroutineinspection,QAshouldcheckwhethertheinspectionsheetismatchedwiththeinspectionoftheproductandthebatches(especiallytheexternalpackaginglogoshouldbefullinspection),otherwisedonotacceptproductinspection,andallreturn;

6.5Forcosmeticdefects,thedistancerequiredbetweenthetwodefectsisDS≧20mm.

Inthe20mm*20mmcanbeacceptabledefectquantity

1defect

7.Cosmeticinspection

7.1CosmeticInspectionstandards

Surface

type

Inspectionstandards

SideA

TPscreen、receiver、thefrontcamera、thetouchbutton

1.AffirmtheTPScreenwithoutscratchandwhitepoint

2.Frontandrearcamera:

Makesurethecameraassembledinplace,deviation、dirtandhairetc.shoulddefinereferringtoacceptable

3.Receivermesh:

deviation、deformation、brokenarenotallowed;

4.Otherareas:

Definereferringtoacceptablestandard;

SideB

Button、USB、thejackofheadset、ThejackofMIC

1.TheUSBwithoutscratch

2.Checkthebuttonwithoutscratch&

paintbelloff&

break&

falloff&

Elastic

3.checktheflankwithoutpaintoff&

leaning&

blockage&

TheUSBwithoutfalloff&

stratification&

clipforeignbody

Batterylip、GIONEELogo、Rearcamera、flashlightarea

1.Logo:

Thelogoisnotallowedtohavedeviation、deformation、excessiveglue、brokenetc.

2.Therearcamera:

Makesurethecameraassembledinplace,deviation、dirtandhairetc.shoulddefinereferringtoacceptablestandard;

3.Flasharea:

Don'

tallowthesubsidence,deviation、dirtandhairetc.shoulddefinereferringtoacceptablestandard;

SideC

Surfacecanbeseenafteropenthebatterycover(includebackcover、batterycompartment、antenna、screw、thebatteryconnector、speaker、Simslot、SDslot)

1.Backcover:

MakesureB-coverandA-coverarebuckledinplace,cosmeticsreferringtoacceptablestandard;

2.Batterycompartments:

Deformationisnotallowed,cosmeticsreferringtoacceptablestandard;

3.Antenna:

Makesuretheantennagluesinplace,excessiveglue、deformation、rakeangleandleakageofcopperetc.defectsarenotallowed.

4.Screw:

Thescrewwhichisnotreachthedesignatedposition、shortshipped,destroyed,isnotallowed,offthepaintreferringtoacceptablestandard;

5.BatteryconnectorandSIMtray:

Shrapnelcan’tbeoxygenation/bending;

6.Speaker:

Checkwhetherthespeakerisassembledinplace,foamcan'

tbedamaged.

7.2GiONEE5615SpecialappearanceInspectionstandards

No.

InspectionContent

DefectItem

InspectionSurface

Standard

Tools

DefectDefinition

Serious

Major

Minor

1

LCD/L