最全最好用的弹簧设计表(弹簧计算公式).xls

《最全最好用的弹簧设计表(弹簧计算公式).xls》由会员分享,可在线阅读,更多相关《最全最好用的弹簧设计表(弹簧计算公式).xls(78页珍藏版)》请在冰豆网上搜索。

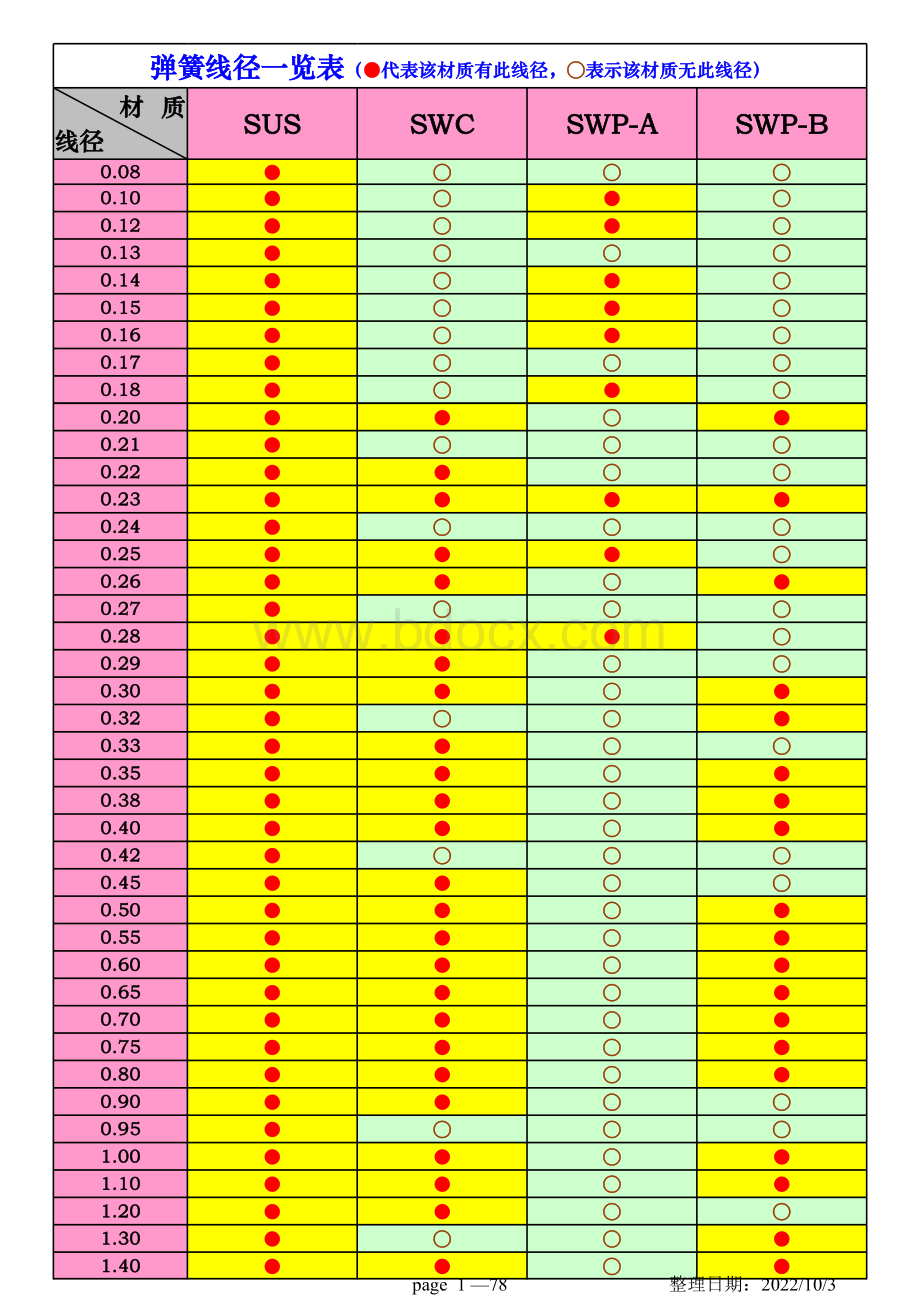

弹弹簧簧线线径径一一览览表表(代代表表该该材材质质有有此此线线径径,表表示示该该材材质质无无此此线线径径)材材质质线线径径SUSSUSSWCSWCSWP-ASWP-ASWP-BSWP-B0.080.080.100.100.120.120.130.130.140.140.150.150.160.160.170.170.180.180.200.200.210.210.220.220.230.230.240.240.250.250.260.260.270.270.280.280.290.290.300.300.320.320.330.330.350.350.380.380.400.400.420.420.450.450.500.500.550.550.600.600.650.650.700.700.750.750.800.800.900.900.950.951.001.001.101.101.201.201.301.301.401.40page178整理日期:

2022/10/31.501.501.601.601.801.802.002.002.302.302.602.602.902.903.003.003.203.20弹弹簧簧线线径径一一览览表表(代代表表该该材材质质有有此此线线径径,表表示示该该材材质质无无此此线线径径)材材质质线线径径SUSSUSSWCSWCSWP-ASWP-ASWP-BSWP-Bpage278整理日期:

2022/10/3适用产品线径d中径D0总圈数N1自由高度H0工作高度H1工作高度H2剪切模量G抗拉强度Bkg/mm2查表有效圈数N作用力F1作用力F2螺旋升角(59)绕旋比C12高径比b(1.3)K脉动疲劳极限0两端磨平两端不磨716002#0GSPA02040.453.567.53.52.87160048.5610.0588.5347.967.7782.1430.6381.20GSPA02060.53.57.5105.54.8716005.510.6712.3358.4658.000772.8570.6491.20GSPA02220.53.51014.57.56.871600811.4212.5578.7258.406774.1430.6821.20716002#0GSPA03140.812.54.511.57.55.3716002.53.0034.65485.7585.295715.630.920.4841.10GSPA03151164.513.59.56.8716002.53.4965.8565.2294.7763160.8440.4481.10GSPA03161.1214.518117.9716002.53.9625.71635.4725.093119.090.8570.521.10GSPA03231.4254.519.513.88.8716002.55.0179.4184.8614.455617.860.780.41.10GSPA03241.6314.525.517.911.4716002.55.98511.1045.2334.859619.380.8230.4041.10G10.32181410.51071600161.9822.26557.5927.42436.66770.6561.20G20.456.55.511.55.55716003.52.2912.48198.4368.082814.441.7690.6921.10G30.55.591510.76.77160072.0653.98656.6036.3687112.7270.3891.10切应力1(0)切应力2(0)压并高度最大压缩率(0.2)共振频率压并力压缩量f1压缩量f2脉动疲劳系数曲度系数K缸径活塞杆径工作面积最低工作压力适用产品下限应力系数两端不磨两端磨平两端不磨两端磨平两端不磨两端磨平两端不磨两端磨平有杆端无杆端单动常入单动常出#00#0053.33#00#DIV/0!

996.111703.152.71.080.9790.920.8333123.39.30910.2744.754.331.1900#DIV/0!

923.110674.253.750.9040.8320.7830.722523.913.6414.834.55.255.331.21300#DIV/0!

987.210865.550.8560.8110.7780.7371735.214.6815.4977.756.331.21300#DIV/0!

#00#0059.33#00#DIV/0!

203.63164.43.60.8730.7850.5630.506696.525.3315.93146.287.331.09100#DIV/0!

1552605.54.50.8380.7440.50.444531.46.9927.86646.788.331.08800#DIV/0!

170.92476.054.950.8450.7740.5860.536339.336.7637.386710.189.331.07400#DIV/0!

125.62367.76.30.9070.8110.4830.432304.7310.3911.625.710.790.331.07900#DIV/0!

123.72308.87.20.8440.770.4550.415226.513.1514.417.614.191.331.07300#DIV/0!

457.95235.75.40.4820.4650.4220.4071594.24.7014.8713.54126.331.22500#DIV/0!

457.14952.9252.480.7580.720.70.66510353.2743.44666.5127.331.09800#DIV/0!

261.750554.50.830.790.430.41803.064.8035.0434.38.3128.331.13100#DIV/0!

0000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000000上限应力系数上下限应力比#DIV/0!

#DIV/0!

#DIV/0!

#DIV/0!

#DIV/0!

#DIV/0!

#DIV/0!

#DIV/0!

#DIV/0!

#DIV/0!

#DIV/0!

#DIV/0!

#DIV/0!

#DIV/0!

#DIV/0!

#DIV/0!

#DIV/0!

#DIV/0!

#DIV/0!

#DIV/0!

#DIV/0!

#DIV/0!

#DIV/0!

#DIV/0!

#DIV/0!

#DIV/0!

圆锥螺旋压缩弹簧计算公式(等螺旋角)编号及适用产品d线径n1总圈数n有效圈数(圆整值)n有效圈数(计算值)D2最大直径D1最小直径H0自由高度H0有效圈数自由高度L展开长度Hb压并高度D2圈径增大D1圈径减小Nz两端各取支承圈FMAX最大工作载荷FZ有弹簧圈接触时的载荷载荷系数F刚度d压并后节距螺旋角0.70.777511.81010661414554.021762.8710.85.212.1761.850.850.3340.570.032GSPA00180.550.555533.018.958.957.457.4511.9611.962.972.9710.51291.479.037.3714.954.210.850.490.490.135GSPA00250.60.666449.49.47.67.610.4810.484.4134.4138.981602.229.527.4813.853.270.850.4670.560.0840.450.4555337.57.55512.612.64.5624.56211.198.20.517.64.914.53.830.850.4820.170.1880.40.444227.57.555#NUM!

#NUM!

#NUM!

#NUM!

#132.550.850.452#NUM!

0.8510.8514425.48141410.610.69.4989.4982.0542.05481550.0814.410.219.147.770.850.4520.040.1030.90.94426.85141410.610.69.5039.5032.5152.51581550.5914.410.2111.289.590.850.4520.30.104115.55.53.52.0223.823.818.818.822.522.55.7035.703213682.452418.615.14.340.850.4520.70.090.80.84.54.52.511119.29.24.0354.0353.2753.2752.541431.7911.68.59132.550.850.4520.710.032备备注注:

1.绿绿色色表表格格表表示示需需手手动动调调整整的的参参数数;2.红红色色数数字字表表示示作作图图时时所所需需表表出出数数据据压并前计算公式t节距G剪切模量Ri任意弹簧圈半径第i弹簧圈fi第i圈接触时变形量(R2-R1nd)Fi第i圈接触时弹簧力(R2-R1nd)R2-R1ndfi第i圈接触时变形量(R2-R1nd)Fi第i圈接触时弹簧力(R2-R1nd)Ki曲度系数Ci旋绕比f