焊接工艺说明样例.docx

《焊接工艺说明样例.docx》由会员分享,可在线阅读,更多相关《焊接工艺说明样例.docx(102页珍藏版)》请在冰豆网上搜索。

焊接工艺说明样例

WeldingProcedureSpecification

焊接工艺说明书

CompanyName(公司名称)__________HuoDaPipeFittingsManufactureCO.,LTD

WeldingProcedureSpecificationNo.(焊接工艺说明书编号)___________RevisionNo.:

_________________________

SupportingPQRNo.(s)(焊接工艺评定记录编号)____________________________________________________

WeldingProcess(es)(焊接方法)____WS/D_______________Type(s)(机械化程度)______Manual(手工)______________________

[Automatic(自动),Manual(手工),Machine(机械),orSemi-Auto(或半自动)]

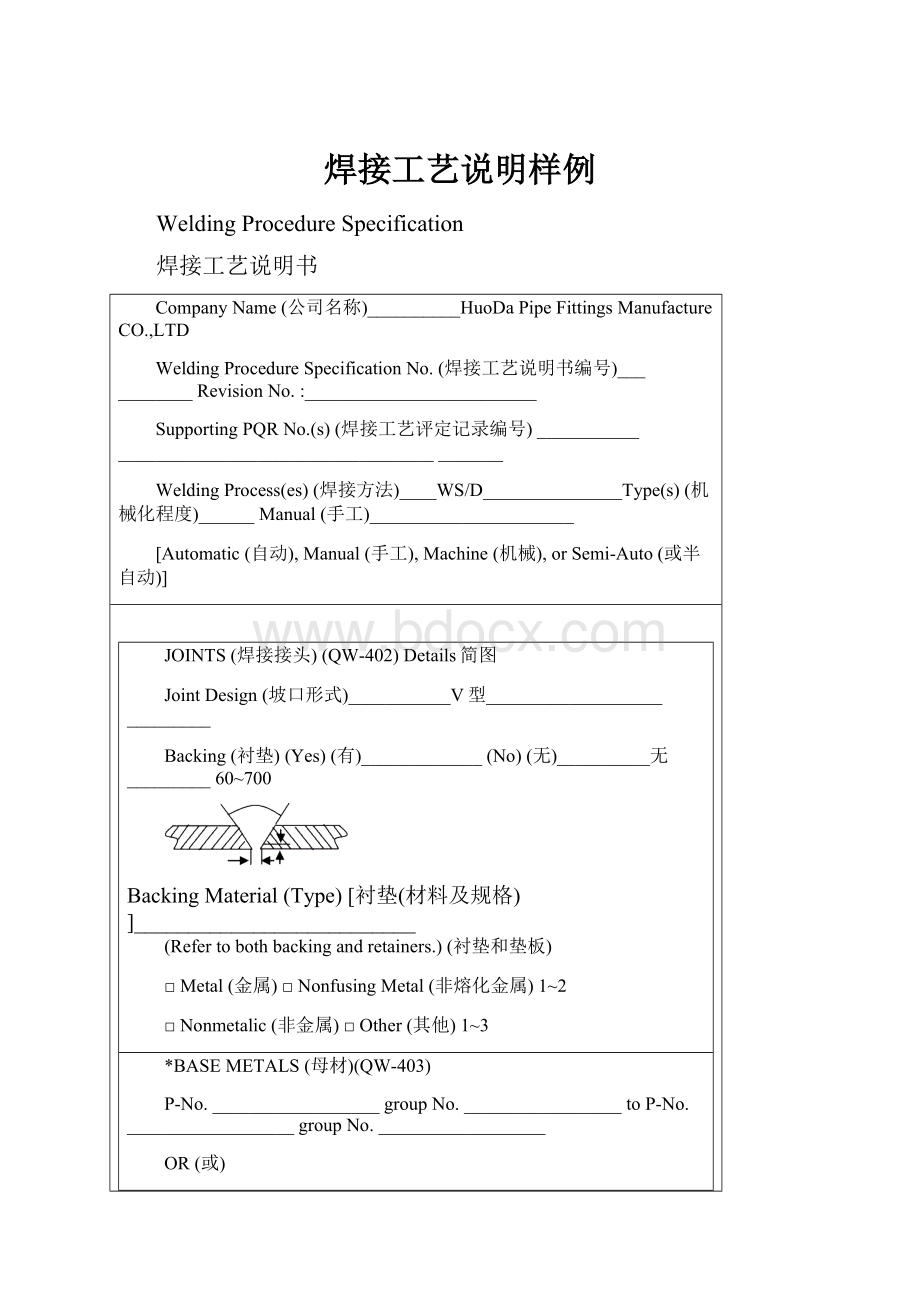

JOINTS(焊接接头)(QW-402)Details简图

JointDesign(坡口形式)___________V型____________________________

Backing(衬垫)(Yes)(有)_____________(No)(无)__________无_________60~700

BackingMaterial(Type)[衬垫(材料及规格)]__________________________

(Refertobothbackingandretainers.)(衬垫和垫板)

□Metal(金属)□NonfusingMetal(非熔化金属)1~2

□Nonmetalic(非金属)□Other(其他)1~3

*BASEMETALS(母材)(QW-403)

P-No.__________________groupNo._________________toP-No.__________________groupNo.__________________

OR(或)

Specificationtypeandgrade(材料形式和级别)__________SA387Gr.91*8__________________________

toSpecificationtypeandgrade(与材料形式和级别)____________________________________________________________

OR(或)

Chem.AnalysisandMech.Prop.(化学分析和力学性能)_________________________________________________________

toChem.AnalysisandMech.Prop.(化学分析和力学性能)______________________________________________________

ThicknessRange(厚度范围):

BaseMetal(母材):

Groove(对接焊缝)______Groove(对接焊缝)_________Fillet(角焊缝)____________

Other(其他)___________________________________________________________________________________________

*FILLERMETALS(焊接材料)(QW-404)

Spec.No.(SFA)(标准号)_________ER90S-B9/E9015-B9______

AWSNo.(Class)(AWS标准号、等级)____________________

F-No._________________________________________________

A-No.

SizeofFillerMetals(焊材规格)____¢2.4/¢3.2__

WeldMetal(焊缝金属)

ThicknessRange(厚度范围):

Groove(对接焊缝)___________6~12_______________

Fillet(角焊缝)_____________________________________

Electrode-Flux(Class)(焊丝-焊剂、等级)_____________________

FluxTradeName(焊剂商标名称)__________________________

ConsumableInsert(可熔性嵌条)___________________________

Other(其他)___

___________________________

_________________

_________________

_________________

_________________

_________________

_________________

_________________

_________________

_________________

_________________

_________________

_________________

*Eachbasemetal-fillermetalcombinationshouldberecordedindividually.对每一种母材与焊接材料的组合均需分别填表

WPSNo.___________________Rev.___________________

POSITION位置(QW-405)

Position(s)ofGroove对接焊缝的位置____全位置_________

WeldingProgression焊接方向(向上、向下):

Up___向上__________Down_____________

Position(s)ofFillet(角焊缝位置)______________________

POSTWELDHEATTREATMENT(焊后热处理)(QW-407)

TemperatureRange(温度范围)____750~770__________

TimeRange(保温时间)___________不小于1小时____

_______________________________________________________

GAS(气体)(QW-408)

PercentComposition(组分百分比)

Gas(es)(Mixture)FlowRate

气体种类混合比流量

__________________________________

Shielding(保护气)_______氩气____________________

Trailing(尾部保护气)_______氩气___________________

Backing(背部保护气)氩气

PREHEAT(预热)(QW-406)

PreheatTemp.Min.(允许最低预热温度)____200________

InterpassTemp.Max.(允许最高层间温度)___低于350___

PreheatMaintenance(保持预热时间)________不小于2小时

(Continuousorspecialheating,whereapplicable,shouldberecorded)(如适用,并应记录连续或特殊加热数据)

ELECTICALCHARACTERISTICS(电特性)(QW-409)

CurrentACorDC(电流种类(交流或直流))___直流_______Polarity(极性)___正接/反接________

Amps(Range)(焊接电流范围)____80~110/90~130________Volts(range)(电弧电压)_10~15/20~30____

(Ampsandvoltsrangeshouldberecordedforeachelectrodesize,position,andthickness,etc.Thisinformationmaybelistedinatabularformsimilartothatshownbelow.)(针对每种焊丝规格、位置和材料厚度等,应记录电流和电压范围,可按以下方式列表记录数据)

TungstenElectrodeSizeandType(钨极类型及直径)_______Wce-20¢2.4_____________________________________

(PureTungsten,2%Thoriated,etc.)

ModeofMetalTransferforGMAW(熔滴过渡形式)_______熔接______________________________________________________

(Sprayarc,shortcircuitingarc,etc.)(PureTungsten,2%Thoriated,etc.)

ElectrodeWirefeedspeedrange(焊丝送进速度)_________________________________________________________________

Weld

Layer(s)焊道/焊层

Process焊接方法

FillerMetal

填充材料

Current

焊接电流

Volt

Range

电弧电压

Travel

Speed

Range

焊接速度

Other(e.g.,Remarks,Comments,HotWireAddition,technique,TorchAngle,etc.)

其它

Class

牌号

Dia.

直径

TypePolar.

极性

Amp

Range

电流

1~2层

3~6层

WS

D

ER90S-B9

E9015-B9

¢2.4

¢2.4

直流正接

直流反接

80~110

90~130

10~15

20~30

焊层厚度不大于4mm,焊条摆动幅度不超过焊条直径4倍

Preparedby:

Approvedby:

acceptedby:

Date:

Date:

Date:

WeldingProcedureSpecification

焊接工艺说明书

CompanyName(公司名称)__HuoDaPipeFittingsManufactureCO.,LTD__

WeldingProcedureSpecificationNo.(焊接工艺说明书编号)___WD-RR-11-2________RevisionNo.:

_________________________

SupportingPQRNo.(s)(焊接工艺评定记录编号)___________HGP92/HGP93__________________________________________

WeldingProcess(es)(焊接方法)____WS/D_______________Type(s)(机械化程度)______Manual(手工)______________________

[Automatic(自动),Manual(手工),Machine(机械),orSemi-Auto(或半自动)]

JOINTS(焊接接头)(QW-402)Details简图

JointDesign(坡口形式)___________对接双V型____________________________

Backing(衬垫)(Yes)(有)_____________(No)(无)__________无_________8~120

BackingMaterial(Type)[衬垫(材料及规格)]__________________________

(Refertobothbackingandretainers.)(衬垫和垫板)

□Metal(金属)□NonfusingMetal(非熔化金属)350

□Nonmetalic(非金属)□Other(其他)

10

0.5~1.5

4~6

*BASEMETALS(母材)(QW-403)

P-No.__________________groupNo._________________toP-No.__________________groupNo.__________________

OR(或)

Specificationtypeandgrade(材料形式和级别)__________SA387Gr.91*24_______________________________

toSpecificationtypeandgrade(与材料形式和级别)____________________________________________________________

OR(或)

Chem.AnalysisandMech.Prop.(化学分析和力学性能)_________________________________________________________

toChem.AnalysisandMech.Prop.(化学分析和力学性能)______________________________________________________

ThicknessRange(厚度范围):

BaseMetal(母材):

Groove(对接焊缝)______Groove(对接焊缝)_________Fillet(角焊缝)____________

Other(其他)___________________________________________________________________________________________

*FILLERMETALS(焊接材料)(QW-404)

Spec.No.(SFA)(标准号)_________ER90S-B9/E9015-B9______

AWSNo.(Class)(AWS标准号、等级)____________________

F-No._________________________________________________

A-No.

SizeofFillerMetals(焊材规格)____¢2.4/¢3.2/¢4_

WeldMetal(焊缝金属)

ThicknessRange(厚度范围):

Groove(对接焊缝)___________14.3~28.6_______________

Fillet(角焊缝)_____________________________________

Electrode-Flux(Class)(焊丝-焊剂、等级)_____________________

FluxTradeName(焊剂商标名称)__________________________

ConsumableInsert(可熔性嵌条)___________________________

Other(其他)___

___________________________

_________________

_________________

_________________

_________________

_________________

_________________

_________________

_________________

_________________

_________________

_________________

_________________

*Eachbasemetal-fillermetalcombinationshouldberecordedindividually.对每一种母材与焊接材料的组合均需分别填表

WPSNo.___________________Rev.___________________

POSITION位置(QW-405)

Position(s)ofGroove对接焊缝的位置____全位置_________

WeldingProgression焊接方向(向上、向下):

Up___向上__________Down_____________

Position(s)ofFillet(角焊缝位置)______________________

POSTWELDHEATTREATMENT(焊后热处理)(QW-407)

TemperatureRange(温度范围)____750~770__________

TimeRange(保温时间)___________不小于2小时____

_______________________________________________________

GAS(气体)(QW-408)

PercentComposition(组分百分比)

Gas(es)(Mixture)FlowRate

气体种类混合比流量

__________________________________

Shielding(保护气)_______氩气____________________

Trailing(尾部保护气)_______氩气___________________

Backing(背部保护气)氩气

PREHEAT(预热)(QW-406)

PreheatTemp.Min.(允许最低预热温度)____200________

InterpassTemp.Max.(允许最高层间温度)___低于350___

PreheatMaintenance(保持预热时间)________不小于5小时

(Continuousorspecialheating,whereapplicable,shouldberecorded)(如适用,并应记录连续或特殊加热数据)

ELECTICALCHARACTERISTICS(电特性)(QW-409)

CurrentACorDC(电流种类(交流或直流))___直流_______Polarity(极性)___正接/反接________

Amps(Range)(焊接电流范围)____80~110/90~130/110~140_Volts(range)(电弧电压)_10~15/20~30____

(Ampsandvoltsrangeshouldberecordedforeachelectrodesize,position,andthickness,etc.Thisinformationmaybelistedinatabularformsimilartothatshownbelow.)(针对每种焊丝规格、位置和材料厚度等,应记录电流和电压范围,可按以下方式列表记录数据)

TungstenElectrodeSizeandType(钨极类型及直径)_______Wce-20¢2.4_____________________________________

(PureTungsten,2%Thoriated,etc.)

ModeofMetalTransferforGMAW(熔滴过渡形式)_______熔接______________________________________________________

(Sprayarc,shortcircuitingarc,etc.)(PureTungsten,2%Thoriated,etc.)

ElectrodeWirefeedspeedrange(焊丝送进速度)_________________________________________________________________

Weld

Layer(s)焊道/焊层

Process焊接方法

FillerMetal

填充材料

Current

焊接电流

Volt

Range

电弧电压

Travel

Speed

Range

焊接速度

Other(e.g.,Remarks,Comments,HotWireAddition,technique,TorchAngle,etc.)

其它

Class

牌号

Dia.

直径

TypePolar.

极性

Amp

Range

电流

1~2层

3~6层

6层以上

WS

D

D

ER90S-B9

E9015-B9

E9015-B9

¢2.4

¢3.2

¢4

直流正接

直流反接

直流反接

80~110

90~130

110~140

10~15

20~30

20~30

焊层厚度不大于4mm,焊条摆动幅度不超过焊条直径4倍

Preparedby:

Approvedby:

acceptedby:

Date:

Date:

Date:

WeldingProcedureSpecification

焊接工艺说明书

CompanyName(公司名称)________HuoDaPipeFittingsManufactureCO.,LTD_____