木门制作及刀具选择.docx

《木门制作及刀具选择.docx》由会员分享,可在线阅读,更多相关《木门制作及刀具选择.docx(11页珍藏版)》请在冰豆网上搜索。

木门制作及刀具选择

木门制作及刀具选择

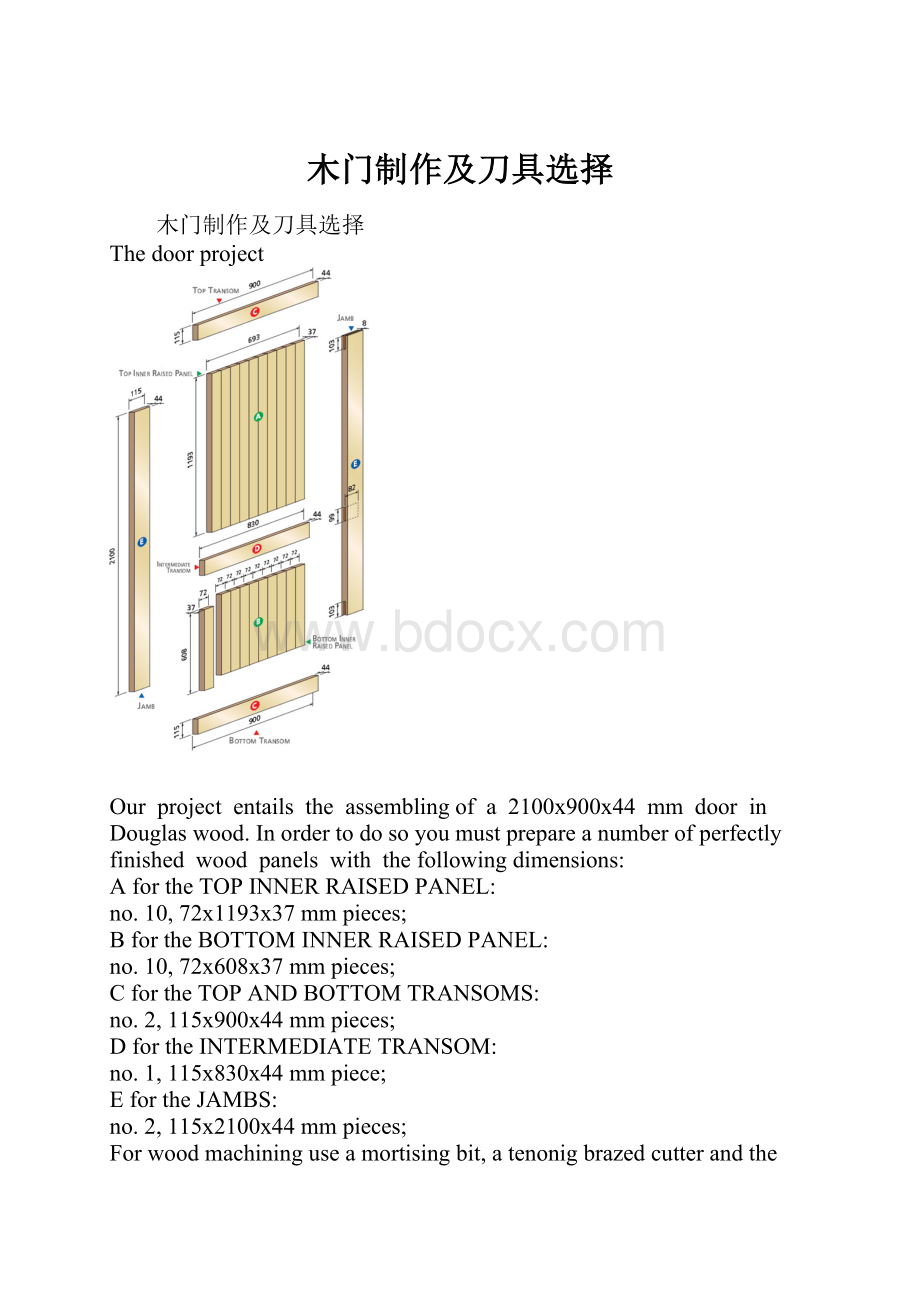

Thedoorproject

Our project entails the assemblingof a 2100x900x44 mm door in

Douglaswood.Inordertodosoyoumustprepareanumberofperfectly

finished wood panels with thefollowingdimensions:

AfortheTOPINNERRAISEDPANEL:

no.10,72x1193x37mmpieces;

BfortheBOTTOMINNERRAISEDPANEL:

no.10,72x608x37mmpieces;

CfortheTOPANDBOTTOMTRANSOMS:

no.2,115x900x44mmpieces;

DfortheINTERMEDIATETRANSOM:

no.1,115x830x44mmpiece;

EfortheJAMBS:

no.2,115x2100x44mmpieces;

Forwoodmachininguseamortisingbit,atenonigbrazedcutterandthe

following tools:

cod.TW23MBF3;

cod.TP42MAB3+CP42MCA3;

cod.TD52MHB3+CT52MTB3.

Firstofallpreparethetop(A)andbottom(B)innerraiseddoorpanels.Mountthefingerjointcutterhead item codeTW23M BF3 on thespindlemoulder.

A.TOPINNERRAISEDPANELWork 9 of the 10,72x1193x37 mm piecesononesideonly.

B.BOTTOMINNERRAISEDPANELWork 9 of the 10,72x608x37 mm piecesononesideonly.

Position the 2,5 mmspacer, supplied withcutterhead item codeTW23MBF3.

A.TOPINNERRAISEDPANELTake8ofthe9previously

machined 72x1193x37mmpieces,plustheonlynonworkedoneandcarry

outthesecondmouldingontheoppositeside.

B.BOTTOMINNERRAISEDPANELTake8ofthe9previously machined72x608x37mmpiecesandtheonlynonworkedoneandcarryoutthe second moulding ontheoppositeside.

Assemble and gluetogetherallthemachinedpieces, holding themtightlytogetherwithaclamp.Whenjoiningthepieces together, makesureyoulaythemoutsoastheyshowoppositeand alternate woodgrains(Fig.3).

Position the tenonigbrazedcutterontothespindlemoulder.

E.JAMBSGROOVINGTENONS

Take2,115x2100x44mmpieces.

Now groove each endofthetopandbottom

jambs. Working depthmust be103mmand8mmthick.

Fixtheknivesontothemultiprofilecutterheadfor doors (item codeTP42MAB3)andcorrectlyposition it onto thespindlemoulder.

C. TOPANDBOTTOMTRANSOMS

Take.2,115x900x44mmpieces.

-FIRSTPHASE-

TENONING

Workoneside,crossgrainofthetwopieces.

C.TOPANDBOTTOMTRANSOMS

-SECONDPHASE-

TENONING

Turn the pieces upsidedownandworkthesamesidecrossgrainagain,aspreviouslydone.

C.TOPANDBOTTOMTRANSOMS

- THIRDANDFOURTHPHASES-

TENONING

Take the two previouslymoulded pieces andrepeat the sameoperationcrossgrain,ontheopposite sideofeachone,asdescribedinsteps5-6.

D.INTERMEDIATETRANSOM

Take1,115x830x44mmpiece.

TENONING

On both sides crossgrain,performthesameoperationsasdescribedinsteps5-6-7.

This photo shows the three transoms, withscribeandtenononbothends.

C.TOPANDBOTTOMTRANSOMS

-SECONDPHASE-

PROFILING

Adjust the tool height.Takethetopandbottomtransoms and profile ononeside,alongthegrain.

C.TOPANDBOTTOMTRANSOMS

-SECONDPHASE-

PROFILING

Turn the two transomsupside down and profilethesamesideaspreviouslyworkedinstep10.

D.INTERMEDIATETRANSOMPROFILING

Take the intermediatetransom and repeat the same operations,workingbothsidesalongthe grain, as in steps 10and11.

E.JAMBS

Now take the two115x2100x44 mm piecesalready machined atboth ends (see Fig. 4).Withan8mmmortisingbit make a slot whichwill allow the fixingof the jamb onto theintermediate transomwhen assembling thedoor.

E.JAMBSPROFILNG

-FIRSTPHASE-

With multiprofilecutterhead TP42M AB3,profile the same piecesas worked in step 13.Machine one side ofeachpiecelenghtways,alongthegrain.

E.JAMBSPROFILNG

-SECONDPHASE-

Turn the previouslymachined pieces upsidedownandcarryoutthesame operationon thesame side length ways,alongthegrain.

Thispicturehighlightsthe jambs slots andthe intermediateandbottomtransomstenons.

Position item codeTD52M HB3 on thespindlemoulder.

A.TOPANDBOTTOM

B.INNERRAISEDPANELS

-FIRSTPHASE-

PROFILING

Workthetwopreviouslyprepared panels on allsides (steps 1-2-3),making sure that youfirst machine the twosidesalongthegrain.

A.TOPANDBOTTOM

B.INNERRAISEDPANELS

-SECONDPHASE-

PROFILING

Turn the panels upsidedownandcarryoutthesameoperationsasthose

describedinstep17.