英文定义.docx

《英文定义.docx》由会员分享,可在线阅读,更多相关《英文定义.docx(41页珍藏版)》请在冰豆网上搜索。

英文定义

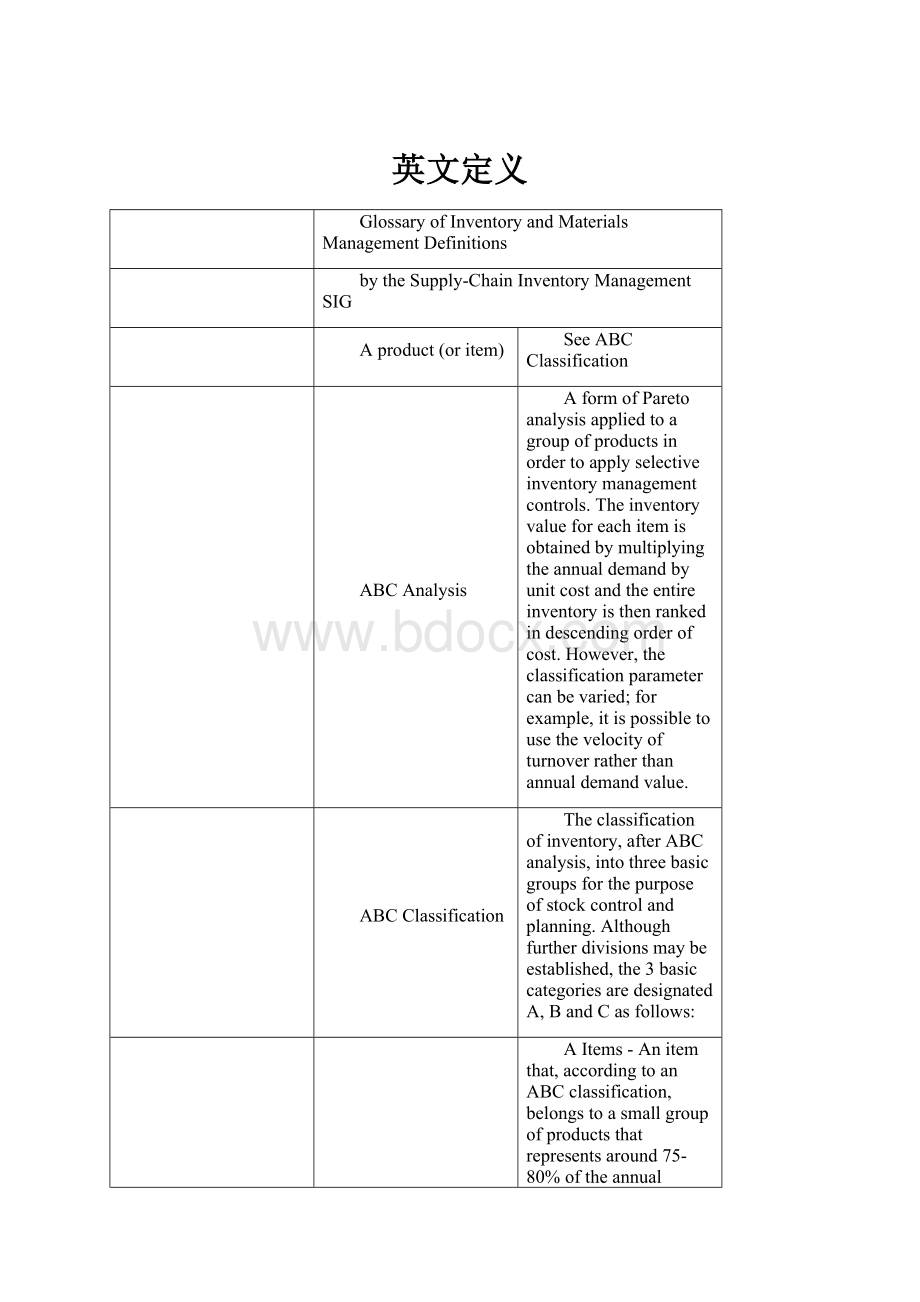

GlossaryofInventoryandMaterialsManagementDefinitions

bytheSupply-ChainInventoryManagementSIG

Aproduct(oritem)

SeeABCClassification

ABCAnalysis

AformofParetoanalysisappliedtoagroupofproductsinordertoapplyselectiveinventorymanagementcontrols.Theinventoryvalueforeachitemisobtainedbymultiplyingtheannualdemandbyunitcostandtheentireinventoryisthenrankedindescendingorderofcost.However,theclassificationparametercanbevaried;forexample,itispossibletousethevelocityofturnoverratherthanannualdemandvalue.

ABCClassification

Theclassificationofinventory,afterABCanalysis,intothreebasicgroupsforthepurposeofstockcontrolandplanning.Althoughfurtherdivisionsmaybeestablished,the3basiccategoriesaredesignatedA,BandCasfollows:

AItems-Anitemthat,accordingtoanABCclassification,belongstoasmallgroupofproductsthatrepresentsaround75-80%oftheannualdemand,usageorproductionvolume,inmonetaryterms,butonlysome15-20%oftheinventoryitems.Forthepurposeofstockcontrolandplanning,thegreatestattentionispaidtothiscategoryofA-products.Aitemsmayalsobeofstrategicimportancetothebusinessconcerned.

BItems-Anintermediategroup,representingaround5-10%oftheannualdemand,usageorproductionvaluebutsome20-25%ofthetotal,thatispaidlessmanagementattention.

CItems-AproductwhichaccordingtoanABCclassificationbelongstothe60-65%ofinventorythatrepresentsonlyaround10-15%theannualdemand,usageorproductionvalue.Leastattentionispaidtothiscategoryforthepurposeofstockcontrolandplanningandprocurementdecisionsforsuchitemsmaybeautomated.

ActiveInventory

Anyitemorelementofinventorywhichhasbeenusedorsoldwithinagivenperiod

AggregateInventoryManagement

Thesizeofmanyinventoriesrequiresthattheybebrokendownintogroupingsforthepurposeofcontrol.Aggregatedinventoryisthefurthercollectionofthesegroupingsintoasingleentitytoenabletheestablishmentofoperatingpolicies,keyperformanceindicators,targetsandreports.AggregateInventoryManagementenablessuchthingsastheoveralllevelofinventorydesiredtobeestablishedandthenappropriatecontrolsimplementedtoensurethatindividualoperatingdecisionsachievethatgoal,atoptimumcost.

AllocatedStock

Apartthathasbeenreserved,butnotyetwithdrawnorissuedfromstock,andisthusnotavailableforotherpurposes

All-TimeOrder

Thelastorderforaparticularproductinthelastphaseofitslifecycle.Thisorderisofsuchasizethatthestockprovidedwillsatisfyallexpectedfuturedemand(seealltimerequirementbelow)fortheproductconcerned.Sometimesknownasalifeoftypeorder.

All-TimeRequirement

Thetotalrequirementforaparticularproducttobeexpectedinthefuture.Normallyusedforproductsinthelastphaseoftheirlifecycles,whenproductionis(nearly)stopped.

All-TimeStock

Thestockresultingfromtheassessmentofanall-timerequirementanddeliveryofanall-timeorder.Ifnecessary,controlscanbesetforsuchstocktoavoidconsumptionofitemsforreasonsoverandabovethoseforwhichusagewaspredicted.

AnticipationStock

Inventoryheldinordertobeableto:

Satisfyademandwithseasonalfluctuationswithaproductionlevelthatdoesnotfluctuateatallorthatvariestoalesserextentthanthedemand

Copewitherraticproductionordeficienciesinproductioncapacity

Availability

Theprimarymeasureofsystemperformancerelatingtotheexpectedpercentageofthesupportedsystemthatwillbeavailableatarandompointintimeandnotoutofserviceforlackofspares.

AvailableStock

Thestockavailabletoserviceimmediatedemand

AvailabletoPromise(ATP)

Theuncommittedportionofacompany’sinventoryandplannedproduction,maintainedinthemasterscheduletosupportcustomerorderpromising.TheATPquantityistheuncommittedinventorybalanceinthefirstperiodandisnormallycalculatedforeachperiodinwhichanMPSreceiptisscheduled.Inthefirstperiod,ATPincludeson-handinventorylesscustomerordersthataredueandoverdue.

BProduct(oritem)

SeeABCClassification

Backflushing

Thedeductionfrominventory,aftermanufacture,ofthecomponentpartsusedinaparentbyexplodingthebillofmaterialsbytheproductiontotalofparentsproduced

Backorder

Acustomerdemandforwhichnostockisavailableandwherethecustomerispreparedtowaitfortheitemtoarriveinstock

BeyondEconomicRepair(BER)

Wheretheprojectedcostofrepair,normallyforarepairableorrotableitem,exceedsamanagementsetpercentageofthereplacementvalueoftheitemconcerned

BarCode

SeeLinearBarCode

BatchNumber

Acodeusedtoidentifythespecificproductionpoint,foraproductoranassembly,inamanufacturingorassemblyprocess

BillofMaterial

Alistingofcomponents,parts,andotheritemsneededtomanufactureaproduct,showingthequantityofeachrequiredtoproduceeachenditem.Abillofmaterialissimilartoapartslistexceptthatitusuallyshowshowtheproductisfabricatedandassembled.Alsocalledaproductstructurerecord,formula,recipe,oringredientslist.

BufferStock

SeeSafetyStock

BuildStock

SeeAnticipationStock

BuildtoOrder

SeeMaketoOrder

C-Product(oritem)

SeeABCClassification

CategoryManagement

Themanagementofgroupsofproductsthatareinterchangeable,orsubstitutable,inmeetingconsumerneedsasopposedtothetraditionalconcentrationonindividualproductsandbrands

Co-ManagedInventory

AsupportarrangementsimilartoVendorManagedInventorybutwherereplacementordersforthevendor-ownedstockareagreedbytheuserpriortodelivery

Component

Apart,ingredient,orsubassemblythatisbothacomponenttoahigherlevelpart,andaparentparttoothercomponents

ComponentPart

Rawmaterial,ingredient,part,orsubassemblythatgoesintoahigherlevelassembly,compound,orotherpart

ConsignmentStock

Thestockofgoodsheldbyanexternalcustomerwhichisstillthepropertyofthesupplierbutforwhichpaymentisonlymadewhenstockissoldorusedbythecustomer

Consumable

Aclassificationofstockusedtodescribeitemsorproductsthataretotallyconsumedinuseegpaper,oil,greaseetc

ContingencyStock

Stockheldtocoverpotentialsystemfailuresituationswhichcanbemathematicallymodeled

ContinuousImprovement(CI)

Atermthatdescribesthemanymanagementpracticesandtechniquesusedtofindandeliminatewasteandtogeneralimprovementsinbusinessprocesses,qualityorcosts

"ControlGroup"CycleCounting

Therepeatedphysicalinventorytakingofasmall"controlgroup"ofparts,inthesamelocations,withinaveryshorttimeframetoverifythedesignofanewinventoryprocess.Itistheonlyformofcyclecountingnottrulyusedtomeasureinventoryrecordaccuracy.

CycleCounting

Cyclecountingisthephysicalcountingofstockonaperpetualbasis,ratherthancountingstockperiodically.Acycleisthetimerequiredtocountallitemsintheinventoryatleastonce.Thefrequencyofcyclecountingcanbevariedtofocusmanagementattentiononthemorevaluableorimportantitemsortomatchworkprocesses.Someofthesystemsusedare:

ABCsystemwiththehighestcountfrequencyforitemswiththehighestannualusagevalue

Reordersystemwhenstocksarecountedatthetimeoforder

Receiversystemwithcountingwhengoodsarereceived

Zerobalancesystemtocountitemswhenabackordersituationisreachedtoconfirmthatnostockisheld

Transactionsystemwherestocksarecountedafteraspecifiednumberoftransactions

CycleStock

SeeWorkingStock

De-CouplingStock

Inventoryaccumulatedbetweendependentactivitiesinthegoodsflowtoreducetheneedforcompletelysynchronisedoperations

DeductPoint

Thepointintheproductionprocessuptowhichallthepartsassumedtohavebeenused(asdefinedinthebillofmaterial)are"backflushed",(automaticallydeducted)fromtheinventoryrecords.AlsoseeBackflushing.

DemandForecast

SeeForecastDemand

DemandSatisfactionRate

SeeFillRate

DenominationofQuantity

SeeUnitofMeasure

DependentDemand

Aclassificationusedininventorycontrolwherethedemandforoneitemhasadirectmathematicalrelationshipwiththedemandforanotherhigherlevelorparentcomponentandwherethedemandforthatitemisultimatelydependentonthedemandforthehigherlevelorparentitem

DeterministicInventoryControlModels

Aninventorycontrolsystemwhereallthevariablesandparametersusedareknown,orcanbecalculatedwithcertainty.Therateofdemandforitems,andtheassociatedinventorycosts,areassumedtobeknownwithassuranceandthereplenishmentleadtimeisassumedtobeconstantandindependentofdemand.

DistributionRequirementPlanningDRPI

Thefunctionofdeterminingtheneedtoreplenishinventoryatbranchwarehousesoveraforwardtimeperiod.Atime-phasedorderpointapproachisusedwhereplannedordersatbranchwarehouselevelareexplodedviaMRPlogictobecomegrossrequirementsonthesupplyingsourceenablingthetranslationofinventoryplansintomaterialflows.Inthecaseofmulti-leveldistributionnetworks,thisexplosionprocesscancontinuedownthroughthevariouslevelsofregionalwarehouses,masterwarehouse,factorywarehouseetcandbecomeinputtothemasterproductionschedule.

DistributionResourcePlanningDRPII

TheextensionofMRPintotheplanningofthekeyresourcescontainedinadistributionsystem

E