Eagle60 维修保养培训手册.docx

《Eagle60 维修保养培训手册.docx》由会员分享,可在线阅读,更多相关《Eagle60 维修保养培训手册.docx(17页珍藏版)》请在冰豆网上搜索。

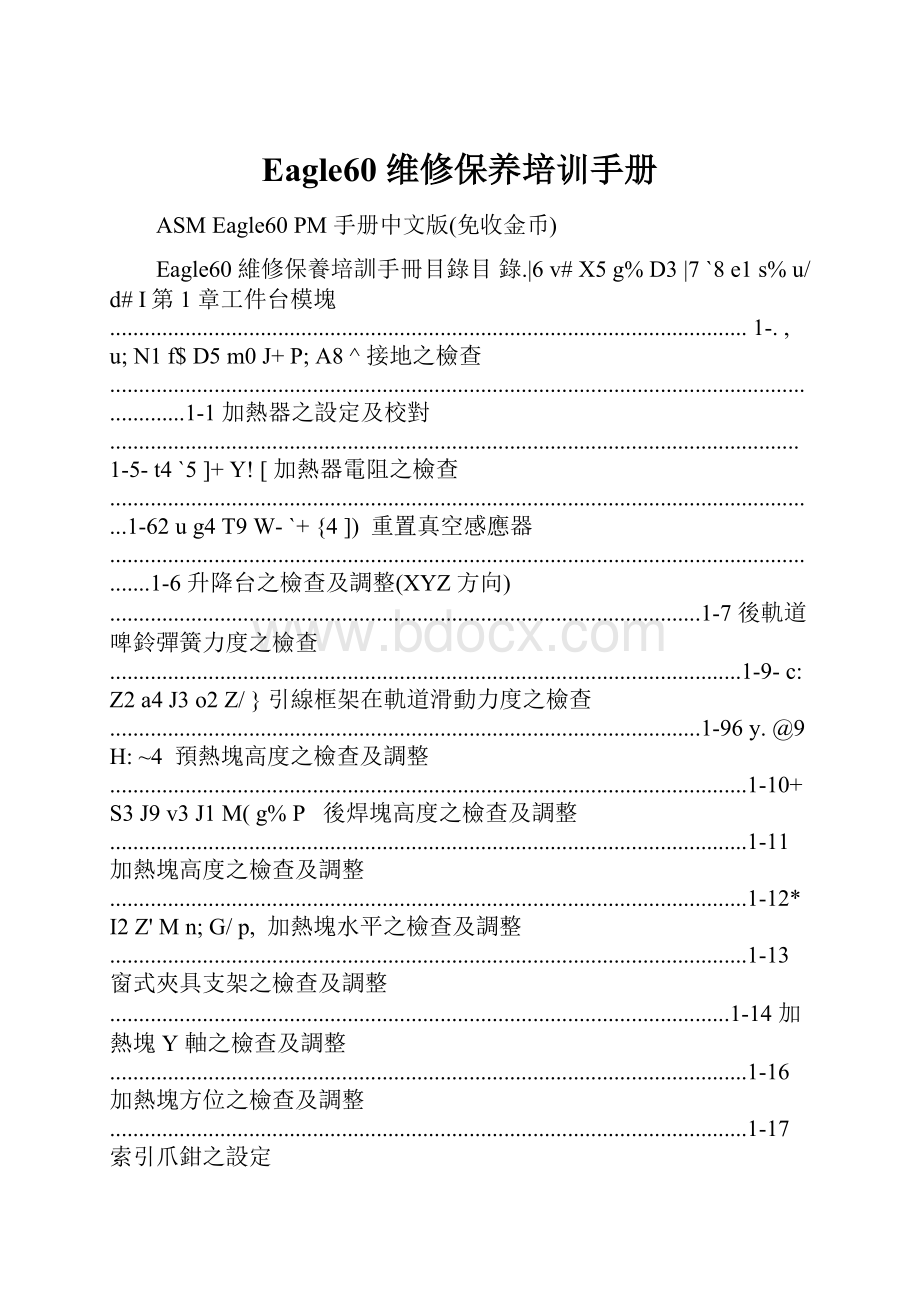

Eagle60维修保养培训手册

ASMEagle60PM手册中文版(免收金币)

Eagle60維修保養培訓手冊目錄目錄.|6v#X5g%D3|7`8e1s%u/d#I第1章工件台模塊..............................................................................................................1-.,u;N1f$D5m0J+P;A8^接地之檢查.....................................................................................................................................1-1加熱器之設定及校對.......................................................................................................................1-5-t4`5]+Y!

[加熱器電阻之檢查...........................................................................................................................1-62ug4T9W-`+{4])重置真空感應器...............................................................................................................................1-6升降台之檢查及調整(XYZ方向)......................................................................................................1-7後軌道啤鈴彈簧力度之檢查.............................................................................................................1-9-c:

Z2a4J3o2Z/}引線框架在軌道滑動力度之檢查......................................................................................................1-96y.@9H:

~4預熱塊高度之檢查及調整..............................................................................................................1-10+S3J9v3J1M(g%P 後焊塊高度之檢查及調整..............................................................................................................1-11加熱塊高度之檢查及調整..............................................................................................................1-12*I2Z'Mn;G/p,加熱塊水平之檢查及調整..............................................................................................................1-13窗式夾具支架之檢查及調整...........................................................................................................1-14加熱塊Y軸之檢查及調整..............................................................................................................1-16加熱塊方位之檢查及調整..............................................................................................................1-17索引爪鉗之設定.............................................................................................................................1-18+A.L:

Y;B4T*{8H:

M,T2工件台線圈之更換.........................................................................................................................1-19-E/H-z4r4H8{第2章調整及校對..............................................................................................................2-."J4V-M0^g6_/d"M"N$Z7T#G5g+線夾位置之檢查...............................................................................................................................2-1線夾縫隙之檢查...............................................................................................................................2-26x$u8[(i(m:

f4線夾力度之校對...............................................................................................................................2-3,g$e*E#y7H:

a*u2焊頭位置之校對...............................................................................................................................2-6焊頭起始彈簧力度之檢查................................................................................................................2-81Y v3A)K+w2d D0F:

NW*焊接力度之校對(感應器).................................................................................................................2-9FORCERATIOADJUSTMENT.............................................................................................................2-127o)P%@%\3E.d"u,N-線拉緊器之清潔.............................................................................................................................2-14'i.w8D~/a1g0O8g2打火杆裝備之拆除及重新裝配.......................................................................................................2-15"g5L4L;e,u.x8W.光学之設定...................................................................................................................................2-17,Ml9m!

E2R6F5{3X#換能器阻力之檢查.........................................................................................................................2-209v0k#Q z-C+l6線盤之設定...................................................................................................................................2-21-E$q5@:

l9m!

L:

FV,~:

n+線盤裝備之清潔.............................................................................................................................2-22添加器之更換及設定.....................................................................................................................2-23:

`2r)\4o2g)F s9m1v:

V"[92S3T%{3J"^Eagle60維修保養培訓手冊9g5N,f"K*B5m3r;\0p0@目錄5G$r.y5~8h8j第3章X.工件台模塊.........................................................................................................3-.1n*E+h2K/O+u X及Y軸線圈之更換及調整.............................................................................................................3-12K4}!

S8f(L0e4T$X及Y軸加油及磨擦力測試之檢查..................................................................................................3-5!

f#g-J'H1G+P7e%X及Y線性馬達之更換及調整.........................................................................................................3-6X及Y馬達歸位及平行度之檢查及調整...........................................................................................3-7第4章線性編碼器之鑑定...................................................................................................4-.X及Y線性編碼器之檢查及鑑定......................................................................................................4-16U.k9m;\m([(O第5章機器之設定..............................................................................................................5-.光学系統基準點(攝像機偏距)..........................................................................................................5-1!

q9e/M3v:

T:

焊尖偏距........................................................................................................................................5-2焊點中心........................................................................................................................................5-3焦距偏離中心.................................................................................................................................5-3接觸搜索........................................................................................................................................5-49x'a1z.V9圖像識別系統設定...........................................................................................................................5-4%S)s7b,@#K9L/w7-N:

T*`Eagle60維修保養培訓手冊"jy,Q(j$j1X#y.m第1章.工件台模塊!

Z'z0T(M+N$Z6M$W6K1n2M第1章.工件台模塊接地之檢查.量測步驟.圖示.78t+c*n:

j;[}3d:

m#n#D$Z3O7e/\以下

(1)~(7)需將焊機的電源關掉、拔掉0g*z$H-z{/@:

~Monitor電源線及拔掉SG(SparkGenerator)前4m"+k3R-v!

C6h(T面的白線(WireClamp):

-E:

@3C0;K.]2{"P

(1)邏輯接地與基座接地.OPEN(j2V)x#P I"s/R1g7h*h2y-_3g.i7\2u*[8Y4s3u&WEagle60維修保養培訓手冊2^&v%U;`"%o第1章.工件台模塊:

e-^1N n.e,L量測步驟.圖示.2f#~&],@+b%S"o

(2)WindowClamp接地與Wire(3)WindowClamp接地與WireClamp電容值5X2x2U+6s'V0c)s<200pF,9m)J%V1X$f/~(4)將SG前面的白線(WireSpool)與SG後面的黑線(Ref)電容值<200pF7w;H4H1r2E;j(5)WireClamp的螺絲與Wire'c-c0O"^#})j9W4V(p(6)WindowClamp接地與SG的接地.SHORT,y!

m"T(G*p%BEagle60維修保養培訓手冊第1章.工件台模塊$n8N%_9n9f8]1I0r%L._7P/|量測步驟.圖示.+I'a-@4q1C3D4D&}1T!

G1y&z(7)BondHead與基座.SHORT以下(8)~(11)先將SG前的WireClamp、Wire#^,J.O1|"c+P+U;j5`Spool的線插回。

(I$O%o!

o-\4Z'Q"{'T2]/j%W7f-w#Y(8)WireSpool接地與WindowClamp接地.3J5t2h'y9t0n#@*H-p&X/_SHORT+u-@'z(\2\%\4k1m(9)Pre-HeaterBlock與WindowClamp接地電阻值<4.(10)HeaterBlock與WindowClamp接地電阻值<4.1O6i4`9N!

B+v!

P:

h8r:

i&p(11)Post-HeaterBlock與WindowClamp接地電阻值<4.Eagle60維修保養培訓手冊第1章.工件台模塊5N#U9u1y,N!

L,o-` m&u;G$e2@,i:

{)N#s*I"k!

N%B%4h6z量測步驟.圖示..N-L5H5Y'V9h以下(12)~(14)須將電源開啟(O:

Z4Q/z*`1O(12)溫度控制器的接地(藍色)與基座電壓<(13)將金線從WireSpool到WireClamp接 }#F7s&k8z,C'L好,測量SG前面WireClamp與WireSpool的電阻值<100.4^8V)E(W:

j9T$J;p(14)測量金線與WireClamp..兩側的電阻值Eagle60維修保養培訓手冊第1章.工件台模塊#U7H#u*_+V5x9E&l S)m+S-|0V,b!

z*a*"加熱器之設定及校對.)n5L2D"L&V3`8D1J9n/VEagle60校正方式:

!

w%h5n-{:

E-e E6H5I/b:

B.Z4I步驟.說明.圖示.1確認溫控器開關是否開啟路徑:

路徑:

O/X-c;A;V1w7}6P&A2選擇預校正之溫控器(Heater、Preheater或Postheater),以下採Heater為例路徑:

Fun15(2002)!

HeaterSetup!

SelectHeater3路徑:

Fun15(2002)!

HeaterSetup!

SetTemperature設定Heater溫度(A)8E2k(r"C&q0{"D%[HeaterPreheaterHeater6j8h$R"x,m,|5J0ZPostheaterHea;`5g/K"S:

]"l1Gter$e0h"{+[ d)p8x4量測Heater實際溫度得數值(B),e6F7h \(r)[:

t5計算預補償之溫度)},P @7c E1\.S1K)b"q(A.B)x=C,G#Y(X,L/j!

Z4U9]0]設定補償溫度:

SetTempOffset(*.C=D:

q7Z/s(F6z,O6進入SetTempOffset(*輸入D值7進入HeaterAutoTune,自動校正即5@'w,F-F/k!

K,Y1V可1W:

t)C7\6B;W;B4F2o8重覆步驟2至步驟6直到實際溫度與量測溫度相同即可(s$~-}+]5@({3t!

Z-m1yEagle60維修保養培訓手冊第1章.工件台模塊加熱器電阻之檢查.流程:

3B;i#h0P:

d&O7~用multi-meter量度pre-heater,heater&postbondheater的電阻:

'\3E$@;G"A4j"F$mPreHeater加熱電阻30~40.0q)l4J "|1k6|5~PostBond加熱電阻60~80.2Q+Q+A!

W"x-I6X"b%r8kHeaterBlock上的加熱器電阻35~45.5P:

W1z!

3f.f!

D:

}0重置真空感應器.Eagle60VacuumSensor設定流程.j)e(P-~1u/r+U步驟.說明.圖示.1準確送導線架進入打線位置,目的在於封住真空孔+{8A3M)^;(X2打開真空開關,並記錄vacuumsensor顯示之數值A3k5u+Q&G+T7J/`路徑:

&n!

B"V%N%K*q-f0^3退出導線架,目的在於釋放真空4打開真空開關,並記錄vacuumsensor顯示之數值B2{7J$s.w1E U6@+@&I l'j4D路徑:

4按鈕1,3同時按,設定為HHD模式5按3使畫面顯示P1使用上下鍵調整數值為.Q0d8L.{#[9h!

S(A+B)/2出機時P1!

設定為3951Q$Z,I'b&Q5t6~!

Z:

6按