运营管理课后习题答案供参考.docx

《运营管理课后习题答案供参考.docx》由会员分享,可在线阅读,更多相关《运营管理课后习题答案供参考.docx(33页珍藏版)》请在冰豆网上搜索。

运营管理课后习题答案供参考

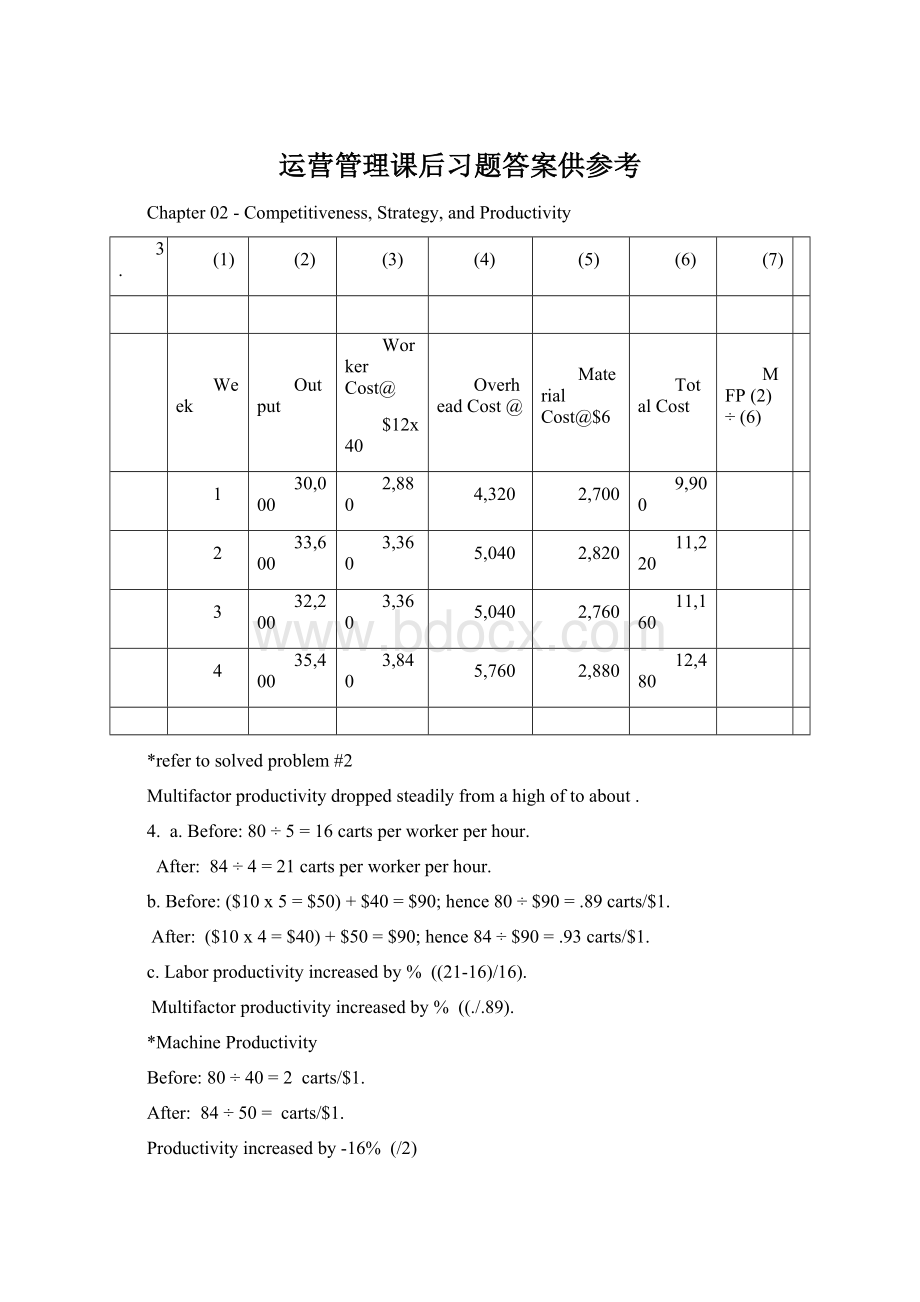

Chapter02-Competitiveness,Strategy,andProductivity

3.

(1)

(2)

(3)

(4)

(5)

(6)

(7)

Week

Output

WorkerCost@

$12x40

OverheadCost@

MaterialCost@$6

TotalCost

MFP

(2)÷(6)

1

30,000

2,880

4,320

2,700

9,900

2

33,600

3,360

5,040

2,820

11,220

3

32,200

3,360

5,040

2,760

11,160

4

35,400

3,840

5,760

2,880

12,480

*refertosolvedproblem#2

Multifactorproductivitydroppedsteadilyfromahighoftoabout.

4.a.Before:

80÷5=16cartsperworkerperhour.

After:

84÷4=21cartsperworkerperhour.

b.Before:

($10x5=$50)+$40=$90;hence80÷$90=.89carts/$1.

After:

($10x4=$40)+$50=$90;hence84÷$90=.93carts/$1.

c.Laborproductivityincreasedby%((21-16)/16).

Multifactorproductivityincreasedby%((./.89).

*MachineProductivity

Before:

80÷40=2carts/$1.

After:

84÷50=carts/$1.

Productivityincreasedby-16%(/2)

Chapter03-ProductandServiceDesign

6.StepsforMakingCashWithdrawalfromanATM

1.InsertCard:

MagneticStripShouldbeFacingDown

2.WatchScreenforInstructions

3.SelectTransactionOptions:

1)Deposit

2)Withdrawal

3)Transfer

4)Other

4.EnterInformation:

1)PINNumber

2)SelectaTransactionandAccount

3)EnterAmountofTransaction

5.Deposit/Withdrawal:

1)Deposit—placeinanenvelope(whichyou’llfindnearorintheATM)andinsertitintothedepositslot

2)Withdrawal—liftthe“WithdrawalDoor,”beingcarefultoremoveallcash

6.Removecardandreceipt(whichservesasthetransactionrecord)

8.

Technical

Requirements

Ingredients

Handling

Preparation

CustomerRequirements

Taste

√

√

Appearance

√

√

√

Texture/consistency

√

√

Chapter04-StrategicCapacityPlanningforProductsandServices

2.

Actualoutput=.8(Effectivecapacity)

Effectivecapacity=.5(Designcapacity)

Actualoutput=(.5)(.8)(Effectivecapacity)

Actualoutput=(.4)(Designcapacity)

Actualoutput=8jobs

Utilization=.4

10.a.Given:

10hrs.or600min.ofoperatingtimeperday.

250daysx600min.=150,000min.peryearoperatingtime.

Totalprocessingtimebymachine

Product

A

B

C

1

48,000

64,000

32,000

2

48,000

48,000

36,000

3

30,000

36,000

24,000

4

60,000

60,000

30,000

Total

186,000

208,000

122,000

Youwouldhavetobuytwo“A”machinesatatotalcostof$80,000,ortwo“B”machinesatatotalcostof$60,000,orone“C”machineat$80,000.

b.Totalcostforeachtypeofmachine:

A

(2):

186,000min÷60=3,100hrs.x$10=$31,000+$80,000=$111,000

B

(2):

208,000÷60=3,hrs.x$11=$38,133+$60,000=$98,133

C

(1):

122,000÷60=2,hrs.x$12=$24,400+$80,000=$104,400

Buy2Bs—thesehavethelowesttotalcost.

Chapter05-ProcessSelectionandFacilityLayout

3.

Desiredoutput=4

Operatingtime=56minutes

Task

#ofFollowingtasks

PositionalWeight

A

4

23

B

3

20

C

2

18

D

3

25

E

2

18

F

4

29

G

3

24

H

1

14

I

0

5

a.Firstrule:

mostfollowers.Secondrule:

largestpositionalweight.

AssemblyLineBalancingTable(CT=14)

WorkStation

Task

TaskTime

TimeRemaining

FeasibletasksRemaining

I

F

5

9

A,D,G

A

3

6

B,G

G

6

–

–

II

D

7

7

B,E

B

2

5

C

C

4

1

–

III

E

4

10

H

H

9

1

–

IV

I

5

9

–

b.Firstrule:

Largestpositionalweight.

AssemblyLineBalancingTable(CT=14)

WorkStation

Task

TaskTime

TimeRemaining

FeasibletasksRemaining

I

F

5

9

A,D,G

D

7

2

–

II

G

6

8

A,E

A

3

5

B,E

B

2

3

–

III

C

4

10

E

E

4

6

–

IV

H

9

5

I

I

5

–

c.

4.

a.l.

2.MinimumCt=minutes

Task

Followingtasks

a

4

b

3

c

3

d

2

e

3

f

2

g

1

h

0

WorkStation

Eligible

Assign

TimeRemaining

IdleTime

I

a

A

b,c,e,(tie)

B

C

E

II

d

D

III

f,g

F

G

IV

h

H

3.

4.

b.1.

2.Assigna,b,c,d,andetostation1:

minutes[noidletime]

Assignf,g,andhtostation2:

minutes

3.

4.

7.

1

5

4

3

8

7

6

2

Chapter06-WorkDesignandMeasurement

3.

Element

PR

OT

NT

AFjob

ST

1

.90

.46

.414

.476

2

.85

3

.83

.913

4

Total

8.

A=24+10+14=48minutesper4hours

9.

a.

Element

PR

OT

NT

A

ST

1

2

.83

.955

3

.56

.588

.676

b.

c.e=.01minutes

Chapter07-LocationPlanningandAnalysis

1.

Factor

Localbank

Steelmill

Foodwarehouse

Publicschool

1.

Convenienceforcustomers

H

L

M–H

M–H

2.

Attractivenessofbuilding

H

L

M

M–H

3.

Nearnesstorawmaterials

L

H

L

M

4.

Largeamountsofpower

L

H

L

L

5.

Pollutioncontrols

L

H

L

L

6.

Laborcostandavailability

L

M

L

L

7.

Transportationcosts

L

M–H

M–H

M

8.

Constructioncosts

M

H

M

M–H

Location(a)

Location(b)

4.

Factor

A

B

C

Weight

A

B

C

1.

BusinessServices

9

5

5

2/9

18/9

10/9

10/9

2.

CommunityServices

7

6

7

1/9

7/9

6/9

7/9

3.

RealEstateCost

3

8

7

1/9

3/9

8/9

7/9

4.

ConstructionCosts

5

6

5

2/9

10/9

12/9

10/9

5.

CostofLiving

4

7

8

1/9

4/9

7/9

8/9

6.

Taxes

5

5

5

1/9

5/9

5/9

4/9

7.

Transportation

6

7

8

1/9

6/9

7/9

8/9

Total

39

44

45

53/9

55/9

54/9

Eachfactorhasaweightof1/7.

a.

CompositeScores

39

44

45

7

7

7

BorCisthebestandAisleastdesirable.

b.

BusinessServicesandConstructionCostsbothhaveaweightof2/9;theotherfactorseachhaveaweightof1/9.

5x+2x+2x=1⇒x=1/9

c.

CompositeScores

A

B

C

53/9

55/9

54/9

BisthebestfollowedbyCandthenA.

5.

Location

x

y

A

3

7

B

8

2

C

4

6

D

4

1

E

6

4

Totals

25

20

=

∑xi

=

25

=

=

∑yi

=

20

=

n

5

n

5

Hence,thecenterofgravityisat(5,4)andthereforetheoptimallocation.

Chapter08-ManagementofQuality

1.

Checksheet

WorkType

Frequency

LubeandOil

12

Brakes

7

Tires

6

Battery

4

Transmission

1

Total

30

Pareto

2

.

Therunchartsseemstoshowapatternoferrorspossiblylinkedtobreaktimesortheendoftheshift.Perhapsworkersarebecomingfatigued.Ifso,perhapstwo10minutebreaksinthemorningandagainintheafternooninsteadofone20minutebreakcouldreducesomeerrors.Also,errorsareoccurringduringthelastfewminutesbeforenoonandtheendoftheshift,andthoseperiodsshouldalsobegivenmanagement’sattention.

4

Chapter9-QualityControl

4.

Sample

Mean

Range

1

MeanChart:

±A2

=±

2

=±

3

UCL=,LCL=

4

RangeChart:

UCL=D4

==

5

LCL=D3

=0=0

6

[Bothchartssuggesttheprocessisincontrol:

Neitherhasanypointsoutsidethelimits.]

6.n=200ControlLimits=

Thus,UCLis.0234andLCLbecomes0.

Sincen=200,thefractionrepresentedbyeachdatapointishalftheamountshown..,1defective=.005,2defectives=.01,etc.

Sample10istoolarge.

7.

Controllimits:

UCLis,LCLbecomes0.

Allvaluesarewithinthelimits.

14.LetUSL=UpperSpecificationLimit,LSL=LowerSpecificationLimit,

=Processmean,σ=Processstandarddeviation

ForprocessH:

ForprocessK:

Assumingtheminimumacceptable

is,since<,theprocessisnotcapable.

ForprocessT:

Since=,theprocessiscapable.

Chapter10-AggregatePlanningandMasterScheduling

7.a.Nobacklogsareallowed

Period

Mar.

Apr.

May

Jun.

July

Aug.

Sep.

Total

Forecast

50

44

55

60

50

40

51

350

Output

Regular

40

40

40

40

40

40

40

280

Overtime

8

8

8

8

8

3

8

51

Subcontract

2

0

3

12

2

0

0

19

Output-Forecast

0

4

–4

0

0

3

–3

Inventory

Beginning

0

0

4

0

0

0

3

Ending

0

4

0

0

0

3

0

Average

0

2

2

0

0

7

Backlog

0

0

0

0

0

0

0

0

Costs:

Regular

3,200

3,200

3,200

3,200

3,200

3,200

3,200

22,400

Overtime

960

960

960

960

960

360

960

6,120

Subcontract

280

0

420

1,680

280

0

0

2,660

Inventory

0

20

20

0

0

15

15

70

Total

4,440

4,180

4,600

5,840

4,440

3,575

4,175

31,250

b.Levelstrategy

Period

Mar.

Apr.

May

Jun.

July

Aug.

Sep.

Total

Forecast

50

44

55

60

50

40

51

350

Output

Regular

40

40

40

40

40

40

40

280

Overtime

8

8

8

8

8

8

8

56

Subcontract

2

2

2

2

2

2

2

14

Output-Forecast

0

6

–5

–10

0

10

–1

Inventory

Beginning

0

0

6

1

0

0

1

Ending

0

6

1

0

0

1

0

Average

0

3

.5

0

.5

.5

8

Ba