Supplier Assessment Report供应商评估表.docx

《Supplier Assessment Report供应商评估表.docx》由会员分享,可在线阅读,更多相关《Supplier Assessment Report供应商评估表.docx(45页珍藏版)》请在冰豆网上搜索。

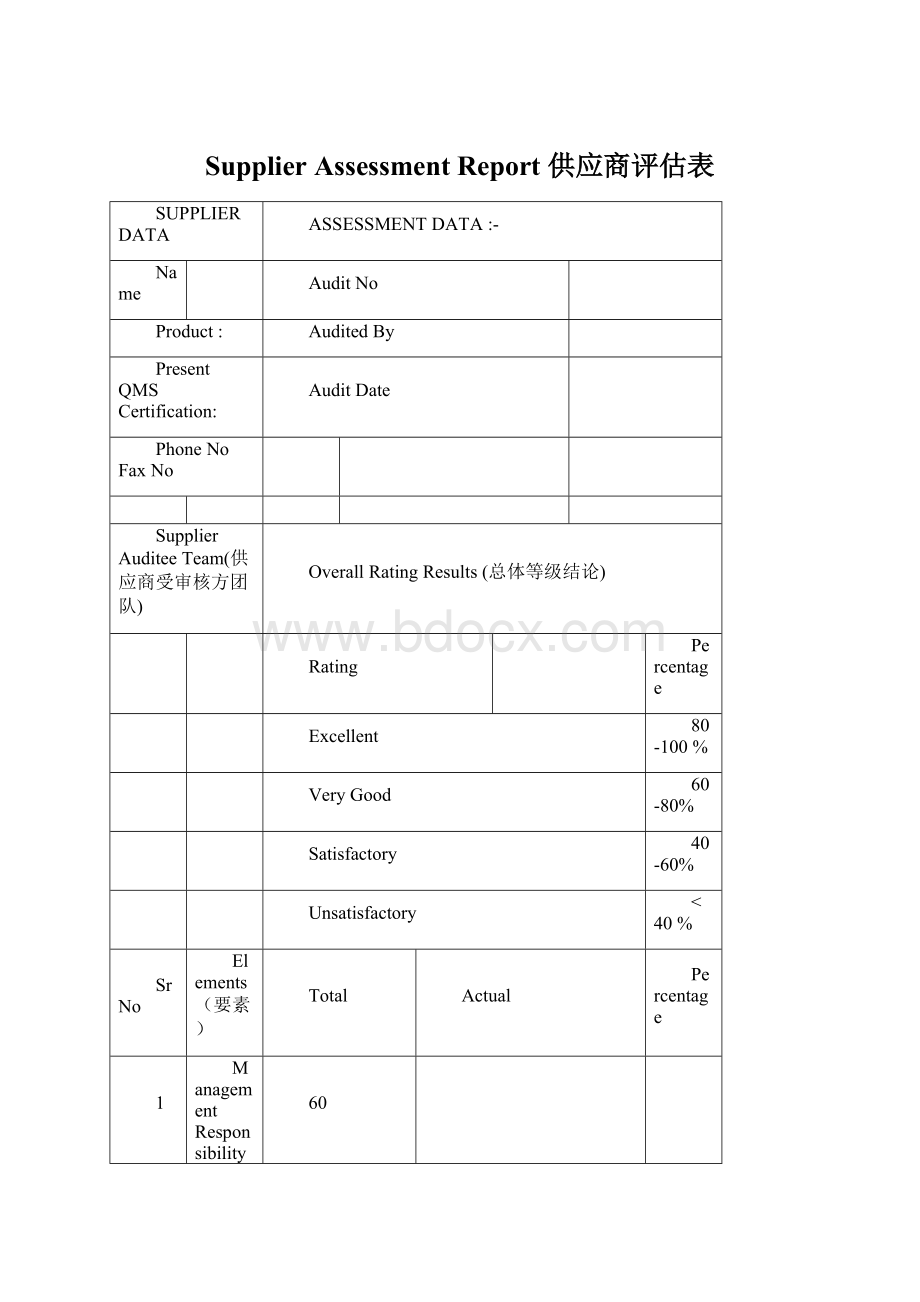

SupplierAssessmentReport供应商评估表

SUPPLIERDATA

ASSESSMENTDATA:

-

Name

AuditNo

Product:

AuditedBy

PresentQMSCertification:

AuditDate

PhoneNoFaxNo

SupplierAuditeeTeam(供应商受审核方团队)

OverallRatingResults(总体等级结论)

Rating

Percentage

Excellent

80-100%

VeryGood

60-80%

Satisfactory

40-60%

Unsatisfactory

<40%

SrNo

Elements(要素)

Total

Actual

Percentage

1

ManagementResponsibility(管理职责)

60

2

QualitySystem

120

3

ContractReview(合同评审)

20

4

DesignControl(设计控制)

60

5

Documents&DataControl(文件与数据控制)

20

6

Purchasing(采购)

40

7

ControlofCustomerSuppliedproduct(顾客提供产品的控制)

10

8

ProductIdentification&Traceability(产品标识与可追溯性)

10

9

ProcessControl(过程控制)

70

10

Inspection&testing(检验与测试)

90

11

Inspection,Measuring&TestEquipment(检验,测量&试验设备)

30

12

ControlofNon-conformingproduct(不合格品控制)

20

13

CorrectiveandPreventiveAction(纠正与预防行动)

50

14

Handling,Storage,Packaging,Preservation&Delivery(操作,贮存,包装,保护,交付)

60

15

ControlofQualityrecords(质量记录控制)

10

16

InternalQualityAudits(内部质量审核)

50

17

People,Training&competency(人员,培训,能力)

40

18

CustomerSpecificRequirements(顾客特殊要求)

20

19

Other

30

Total:

-

810

1.KEYTOASSESSMENTRATING

Thesubcontractorqualityassurancemeasuresareratedwithpointsfrom0to10onthebasisofthefollowing.Onlythoseareasofthesubcontractorthatbearrelevancetotheproduct/serviceofferedbythesubcontractorto‘TACO’needbeassured.(分供方质量保证方法被从0~10分进行分级。

NTACO分供方的与产品/服务相关的方面必须得到保证)

ElementsofsubcontractorQAsystem(分供方质量体系要素)AssessmentObservation(评估结论)

Result

(AssessmentPoints)

NonExistent(不存在)

0

Unsuitableapproaches(不适宜的做法)

1

Majorshortcomings(主要的不足)

3

Minorshortcomings(次要的不足)

5

Appropriate(合适的)

7

Verygood(很好的)

9

Excellent(优秀的)

10

ELEMENTSNOTAPPLICABLETOAPARTICULARSUBCONTRACTOR(不适合特殊分供方的条款)

Certainelementssuchas4.7(ControlofCustomerSuppliedProduct)and4.19(Servicing)willnotapplytoeverysupplier.Insuchcases,‘N/A’isenteredinplaceofthescore.

REPORTINGOFASSESSMENTFINDINGS(审核结果的报告)

Thesupplierassessmentreportshallbefiledalongwiththisassessmentformforreportingandrecommendationonsupplierselectionandapproval.(供应商评估报告应连同此评估表格作为报告、建议新供方的选择以及批准)

MINIMUMCRITERIAFORACCEPTANCE(新供方接受的最小准则)

Thesupplier(includingSpeciallydesignatedsmallsupplier(包括指定的特别小供方))shouldscoreminimum40-60%&scoreminimum5pointsonthefollowingelementsindividuallyforacceptanceasapprovedsupplier.(至少得分在40-60%以及至少分别在下面条款中得到5分,方可批准为供方)

1.Productidentificationandtraceability.(产品标识与可追溯性)

2.Controlplan.(控制计划)

3.Contractreview.(合同评审)

4.Controlofcustomersuppliedproducts.(顾客财产保护)

5.Processmonitoringoperationinstructions.(过程监控作业指导书)

6.Controlofnonconfirmingproducts.(不合格品控制)

7.Inspectionstatus.(检验状况)

8.Calibrationstatus.(校验状况)

9.Correctiveactiononcustomercomplaints.(客户抱怨纠正行动)

10.Compliancewithcustomer'sstandards/requirements.(遵守客户标准与要求)

11.Controlofqualityrecords(质量记录控制)

2.CHECKLISTS(检查清单)

Question(问题表)

AssessorNotes(评估记录)

Result(结果)

1.0ManagementResponsibility(管理职责)

1.1Hastheresponsibility,authority,interrelationshipofpersonnelwhomanage,perform,andverifywork,affectingqualitybeendefinedanddocumented?

(管理、运行、验证、影响质量的人的职责、权限、沟通是否被明确以及文件化)

1.2Doesthesupplier’smanagementwithexecutiveresponsibilityreviewallqualitysystemelementsatdefinedintervalstoinsureitscontinuingsuitabilityandeffectiveness?

(是否定期评审供应商管理体系的要求以保证其是适合与有效的)

1.3Doesthesupplierutilizeaformal,documented,comprehensivebusinessplanthatincludesshort-termandlonger-termgoalsandplans?

(供应商是否有正式文件化的并可理解的运营计划,其应包含短期与长期的目标与计划)

1.4Aretrendsindataandinformationcomparedwith:

(趋势是否于…比较在数据与信息方面)

-Competitors(竞争对手)

-Appropriatebenchmarks(适当的基准)

-Progresstowardbusinessobjectives,toleadtoappropriateactiontosupport(朝着运营目标的进展,引导适宜的活动支持)

▪Developingprioritiesforresolvingcustomerproblems(优先解决客户的问题)

▪Determinationofkeycustomer-relatedtrends?

(对主要客户有关的趋势的测定)

1.5AreManagementReviewconductedwithreviewon(管理评审是否依据…评审)

ProductRealisation(CoreProcesses)including,SupportProcesses,CustomerrequirementsandQualityObjectives.(产品实现(核心流程),支持过程,顾客要求与质量目标)

Note:

Canbeexcludedincaseofspeciallydesignatedsmallsupplier(可以被排除,除非特别指定的供应商)

1.6DoestheManagementreviewparticipateinResourceplanningandCommunicationtoensureeffectiveimplementationandadherencetoQualityManagementSystem.(管理评审是否有充分的资源策划/沟通以保证有效实施以及对质量管理体系的符合)

Note:

Canbeexcludedincaseofspeciallydesignatedsmallsupplier(可以被排除,除非特别指定的供应商)

2.0QualitySystem(质量体系)

2.1IstheDocumentedQualityManagementSysteminLinewithTS16949/QS9000/ISO9000.Arethereadequatesupportingprocedures(level2)foreachelementofthequalitymanual?

(文件化的质量管理体系是否根据TS16949/QS9000/ISO9000。

对于质量手册中的每一个要素是否有充分的支持程序)Note:

Canbeexcludedincaseofspeciallydesignatedsmallsupplier(可以被排除,除非特别指定的供应商)

2.2AreQualityPolicy,Objectives,Exclusions,Processes,Sequences&InteractionofprocessesaredefinedinQMS.(在质量管理体系中质量方针/目标,排除,过程,过程的顺序以及相互作用是否被明确)

2.3IsthereaDesignatedRepresentativeforMR,CustomerRepresentativeandQualityResponsibility.(针对管理者代表/客户代表质量责任/是否有一个指定的代表)

Note:

Canbeexcludedincaseofspeciallydesignatedsmallsupplier(可以被排除,除非特别指定的供应商)

2.4IstheorganisationContinuallyimprovingEffectivenessofQualityManagementSystemsindicatingimprovementtrends(MR,ORetc.).(组织是否持续地对质量管理体系的有效进行改善并显示改善趋势)Note:

Canbeexcludedincaseofspeciallydesignatedsmallsupplier(可以被排除,除非特别指定的供应商)

2.5Isthequalityplanningprocessconsistentwithallotherrequirementsofthequalitysystem,documentedinasuitableformat?

(质量策划过程是否与其它质量体系的要求保持一致,并以合适的表格进行记录)Note:

Canbeexcludedincaseofspeciallydesignatedsmallsupplier(可以被排除,除非特别指定的供应商)

2.6Ismanufacturingfeasibilityinvestigated,confirmed,anddocumented,priortocontractingproposedproducts?

(在签约意向的产品前,其制造可行性是否被调查,确认以及记录)

2.7Areerrorproofingtechniquesutilizedwhereappropriate,whichincludeplanningorprocess,facilities,equipmentandtooling,andinproblemresolution?

(防错技术是否被应用在合适的环节,其应针对策划或过程,设施,设备,模具以及问题解决)

2.8Docontrolplansdevelopedbymulti-disciplinaryapproachtosystem,componentand/ormateriallevel,andlistofallcontrolsusedforprocesscontrol?

(控制计划是否通过参照多学科系统方法,部件,材料等级以及被用于过程控制的控制手段清单被开发)

2.9Docontrolplanscoverthreephases:

prototype,pre-launch,andproduction,asrequiredbythecustomer?

(依据客户的要求,控制计划是否包含三个阶段:

样件、试生产、生产)

2.10Arecontrolplansreviewedandupdatedasappropriatewhenanyofthefollowingoccurs:

(当有以下情形发生时,控制计划是否被适时地评审与更新)

Productandprocesschanges(产品与过程变更)

Processesarefoundtobeunstableornon-capable(过程被发现不适合或者没有能力)

Inspectionmethod,frequency,etc.isrevised?

(检验方法,频率等等被修改)

-

2.11Isthereevidenceofcontinualimprovementinquality,serviceandpricethatbenefitthecustomer?

(是否有证据表明在质量、服务、价格方面的持续改进使客户受益)

2.12Isamulti-disciplinaryapproachusedfordevelopingfacilities,equipment,andprocessplanninginconjunctionwiththeadvancedqualityplanningprocess?

(针对设备,过程计划的开发是否有多学科方法被使用并结合先期质量策划过程)

Note:

Canbeexcludedincaseofspeciallydesignatedsmallsupplier(可以被排除,除非特别指定的供应商)

3.0ContractReview(合同评审)

3.1Arerecordsofcontractreviewsmaintained?

(合同评审的记录是否被保持)

Note:

Canbeexcludedincaseofspeciallydesignatedsmallsupplier(可以被排除,除非特别指定的供应商)

3.2IsFeasibilityandRiskanalysisbeingcoveredpreliminarytoContractreview.(在合同评审中,可行性与风险分析是否初步被总结)

Note:

Canbeexcludedincaseofspeciallydesignatedsmallsupplier(可以被排除,除非特别指定的供应商)

4.0DesignControl(Product&ProcessDesign)(产品&过程设计)

4.1DOthefollowingexist:

-AppropriateresourcesandfacilitiesavailabletouseCAD,CAEandAnalysis?

(是否有适当的可利用资源与设备用于CAD,CAE及其分析的使用)

-AreCAD/CAEsystemscapableoftwo-wayinterfacewithcustomersystems?

(CAD/CAE系统是否有双向接口用于对客户的系统对接)

-Note:

Canbeexcludedincaseofspeciallydesignatedsmallsupplier(可以被排除,除非特别指定的供应商)

4.2Aretherecordsofformaldocumenteddesignreviewsbytheappropriatefunctionsconductedatappropriatestagesofdesignasperthedesignplan?

(按照设计策划,正式的文件化的设计评审记录是否依据适宜的设计平台)

Note:

Canbeexcludedincaseofspeciallydesignatedsmallsupplier(可以被排除,除非特别指定的供应商)

4.3Whenrequiredbythecustomer,doesthesupplierhaveacomprehensiveprototypeprogram?

(当客户提出需求时,供应商是否有全面的样件管理程序)

Note:

Canbeexcludedincaseofspeciallydesignatedsmallsupplier(可以被排除,除非特别指定的供应商)

4.4Istheperformancetestingtrackedfortimelycompletionandconformance?

(性能测试的完成与符合是否被及时跟踪)

4.5TimelyReview,Distribution&CompletionofallCustomerSpecification/Standard.(Reviewwithin2WeeksforcustomerspecificationsandChangerequests))(及时评审,分布&完成客户的所有规范/标准。

在两周内完成对客户的规范以及变更要求的评审)

4.6EffectiveChangeimplementationdateandverification,ValidationandcommunicationofChanges(Product&Process)tocustomer.(针对客户,进行有效的变更实施,验证,批准以及变更沟通)

5.0DocumentandDataControl(文件与数据控制)

5.1Aredocumentsanddatareviewedandapprovedbyauthorizedpersonnelpriortoissue?

(文件与数据在发行前,是否由有权力人员进行评审与批准)

5.2Isthereamasterlistidentifyingdocumentrevisionstatusreadilyavailable?

(是否有一个主清单便利地用于标识文件的版本状态)

6.0Purchasing(采购)

6.1Aresubcontractorsevaluatedandselectedbasedonheirabilitytomeetqualitysystemandqualityassurancerequirements?

(分供方是否在其满足质量体系以及质量保证要求的基础上被评估,选择)

6.2Doesthesupplierdefinetheappropriatetypeandextentofcontroloversubcontractors?

(供应商是否对分供方的控制类型与范围进行定义)

6.3Arequalityrecordsofacceptablesubcontractor