机械毕业设计英文外文翻译492无级变速器.docx

《机械毕业设计英文外文翻译492无级变速器.docx》由会员分享,可在线阅读,更多相关《机械毕业设计英文外文翻译492无级变速器.docx(15页珍藏版)》请在冰豆网上搜索。

机械毕业设计英文外文翻译492无级变速器

附录A

ABSTRACT

HighclampingforcelevelsreducetheefficiencyoftheContinuouslyVariableTransmission(CVT).However,highclampingforcelevelsarenecessarytopreventslipbetweenthebeltandthepulleys.Ifasmallamountofslipisallowed,theclampingforcelevelcanbereduced.Toachievethis,slipinaCVTisinvestigated.Frommeasurementsonanexperimentalsetup,Tractioncurvedataandefficiencymeasurementsarederived.AmodeldescribingslipinaCVTisverifiedusingmeasurementswithabeltwithincreasedplay.Itisfoundthatsmallamountsofslipcanbecontrolledinastablewayonthesetup.ThetractioncurvewasmostlydependentontheCVTratio.Efficiencyisfoundtobehighestfor1to2%slipdependingontheratio.Themodelisinreasonableagreementwiththemeasurements.

1.Introduction

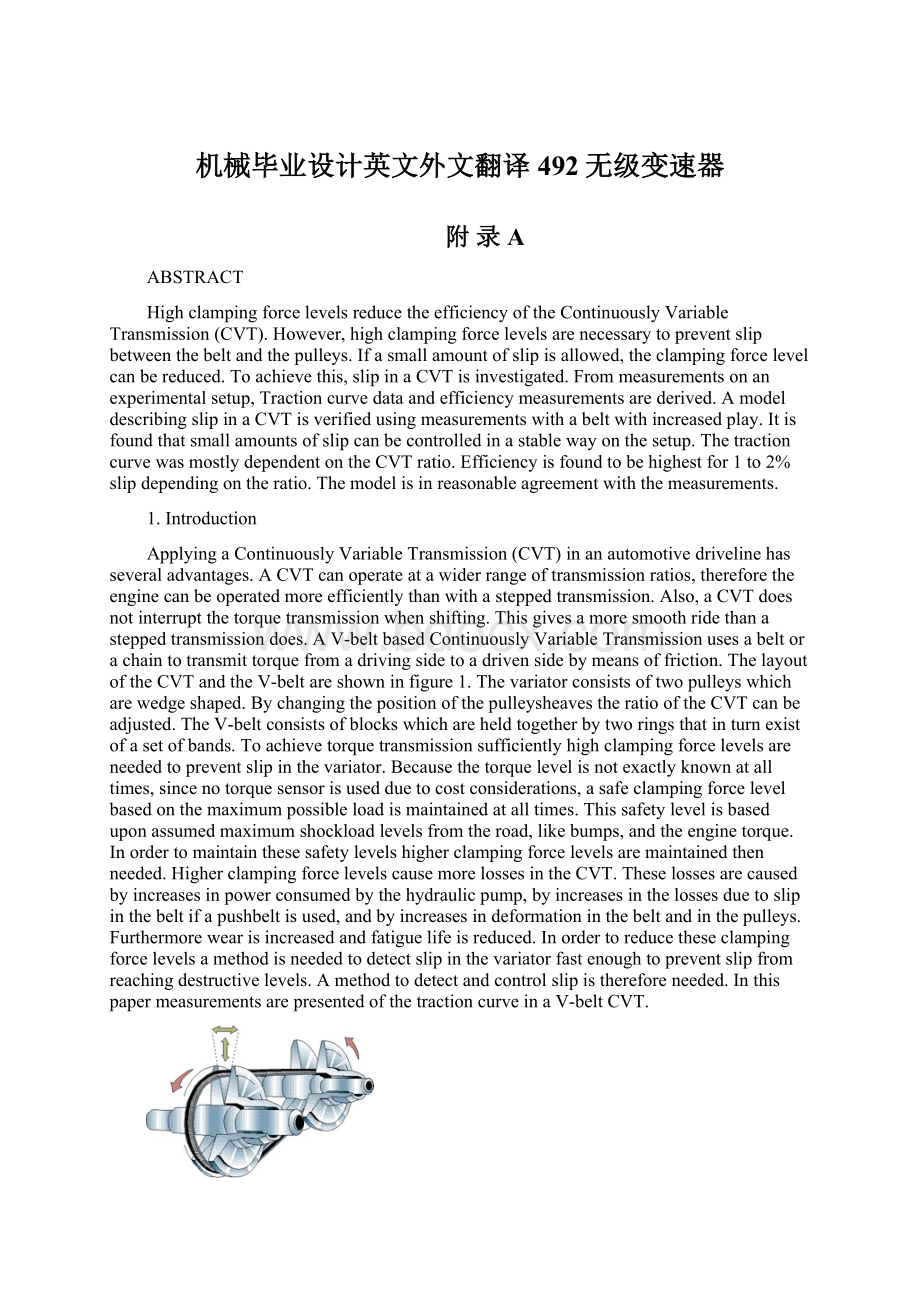

ApplyingaContinuouslyVariableTransmission(CVT)inanautomotivedrivelinehasseveraladvantages.ACVTcanoperateatawiderrangeoftransmissionratios,thereforetheenginecanbeoperatedmoreefficientlythanwithasteppedtransmission.Also,aCVTdoesnotinterruptthetorquetransmissionwhenshifting.Thisgivesamoresmoothridethanasteppedtransmissiondoes.AV-beltbasedContinuouslyVariableTransmissionusesabeltorachaintotransmittorquefromadrivingsidetoadrivensidebymeansoffriction.ThelayoutoftheCVTandtheV-beltareshowninfigure1.Thevariatorconsistsoftwopulleyswhicharewedgeshaped.BychangingthepositionofthepulleysheavestheratiooftheCVTcanbeadjusted.TheV-beltconsistsofblockswhichareheldtogetherbytworingsthatinturnexistofasetofbands.Toachievetorquetransmissionsufficientlyhighclampingforcelevelsareneededtopreventslipinthevariator.Becausethetorquelevelisnotexactlyknownatalltimes,sincenotorquesensorisusedduetocostconsiderations,asafeclampingforcelevelbasedonthemaximumpossibleloadismaintainedatalltimes.Thissafetylevelisbaseduponassumedmaximumshockloadlevelsfromtheroad,likebumps,andtheenginetorque.Inordertomaintainthesesafetylevelshigherclampingforcelevelsaremaintainedthenneeded.HigherclampingforcelevelscausemorelossesintheCVT.Theselossesarecausedbyincreasesinpowerconsumedbythehydraulicpump,byincreasesinthelossesduetoslipinthebeltifapushbeltisused,andbyincreasesindeformationinthebeltandinthepulleys.Furthermorewearisincreasedandfatiguelifeisreduced.Inordertoreducetheseclampingforcelevelsamethodisneededtodetectslipinthevariatorfastenoughtopreventslipfromreachingdestructivelevels.Amethodtodetectandcontrolslipisthereforeneeded.InthispapermeasurementsarepresentedofthetractioncurveinaV-beltCVT.

Figure1.LayoutofaCVTandametalpushbelt

2.Tractioncurve

TheV-belttypeCVTutilizesfrictiontotransmitpowerfromtheprimarypulleytothesecondarypulley.Thetractioncurveisthedimensionlessrelationshipbetweentransmittedtorqueandtheslip.ThemaximuminputtorquethatcanbetransmittedbytheCVTisdependentontheappliedclampingforce.Thetractioncoefficientisthereforechosentobeadimensionlessvalue.Thetractioncoefficientμisdefinedas:

(1)

Inwhich

representstheinputtorque,

representsthesecondaryrunningradiusofthebeltonthepulley,

representsthesecondaryclampingforceand

isthepulleywedgeangle.

Figure2.CVTtorquetransmissionscheme

Thesecondvariableinthetractioncurveistheslipinthevariator.

Slipisdefinedas:

(2)

Where

istheangularspeedofthesecondaryaxle,

istheangularspeedoftheprimaryaxleand

isthegeometricalratio,whichisdefinedby:

(3)

istherunningradiusontheprimarypulley.

2.1Tangentialslip

Slipisdefinedinequation2.WhentheCVTtransmitspoweracertainamountofslipcanbemeasuredalmostlinearwiththeappliedtorque.ThisiscalledthemicroslipregimeoftheCVT,becausetractionisstillincreasinginthisregimewithincreasingslip.Themicroslipiscausedbygapsbetweentheblocksontheidlepartofthedrivingpulleyasshowninfigure3.Onthedrivingpulleyanidlearcexistswherenoslipoccurs.Alsoanactivearcexists(seefigure2),whereslipoccursrelativetothetotalplayinthebeltandtheactivearclength.However,whenthemaximumtorquecapacityoftheCVTisreachedslipwillincreasedramatically.Thissituation,macroslip,isnotstableduringnormaloperationoftheCVT,becausethetractioncoefficientdecreaseswithincreasedslipspeed.Itisassumedthatthetotalgapdtisevenlydistributedalongtheidlearcofthedrivingpulley.Thetraction

Figure3.Gapsinthebelt

curve(figure5)showsthattorquetransmissionincreasesalmostlinearlywithanincreaseinslip,untilacertainmaximumtorqueisreached.dtcanbeestimatedbyaddinganinitialgapdototheincreaseinbeltlengthduetotheinternalstressesinthebandsandadecreaseinlengthoftheblocksduetothecompressiveforces.

(4)

Tocalculatetheslipcausedbythesegapswecanusethefollowingequations:

(5)

(6)

Inequation5,aistheidlearc,disthewidthofabeltelementanddtisthetotalgapbetweentheelementsinthebelt.Tocalculatetheamountofslipthetotalgapdthastobeknown.Thiseffecthasaninfluenceonthetractioncoefficientinthemacroslipregime.Whenmacroslipoccursthetractionwilldecreasewithincreasingslip.TheStribeckeffectismodelledusingequation9.

(7)

(8)

(9)

Equation7givesavalueforthefrictioncausedbyviscousfrictioncomponent.Equation8givesavalueforthecoulombfrictioncomponent.a0,1,c0andv1arecoefficientswhichcanbechosentomatchthemeasuredvalues.Withtheseequationswecanderiveslipandtractionfrommeasureddataasshowninsection4.WithAsayama[1995]wecanobtainthetensionandcompressionforcedistributionneededtocalculatethelengtheningofthebelt.Also,wecancalculatetheidlearcfromthismodel.Fromtheidlearc,thelengthofthebeltandtheinitialgapwecancalculateanestimateforslipinthebeltforagivenload.

2.2Radialslip

Notonlyslipintangentialdirectionoccurs,butalsoslipinradialdirection.Thefirstreasonforradialslipisspiralrunning.Whenthebeltrunsalongthearcofcontacttheradiusatwhichitrunsisnotconstant.Thiseffectiscausedbypulleydeformation.Onetypeofdeformationisthebendingoftheaxlebetweenbothpulleysheaves.Thebeltisnotfullywrappedaroundthepulley,thereforetheresultingnormalforceoftheblocksonthepulleyisnotaxial.Thiscausesabendingmomentintheaxle.

Asecondeffectisthebendingofthepulleyitself.Thiseffectismostlydependentonthelocalnormalforceexertedonthepulleybytheblocks.Thiseffectissmallwhenthebeltisrunningonasmallrunningradius,butonalargerunningradiusthiseffectissignificant.Thesecondreasonforslipinradialdirectionisduetoshifting.WhentheCVTisshiftedtoadifferenttransmissionratio,radialslipisforced.Thisisdonebychangingtheclampingforceratio.Theamountofradialslipthatisforceddependsontheshiftingspeedandthe(primary)angularspeed.

3.Experimentalsetup

Intheexperimentsthegeometriccvtratioisfixedandtheclampingforcesareconstant,thetractioncoefficientthendependsonlyontheslipinthesystem.Thetractioncurvecanbeconstructedfromoutputtorqueandslipmeasurements.Thetestrigmotorsdeliveramaximumtorqueof298Nmwithamaximumspeedof525rad/s.BothmotorsareequippedwithaHeidenhainERN1381incrementalrotaryencoderwith2048pulses/rev.ThetorqueatbothsidesismeasuredusingaHBMT20WNtorquesensor.Themaximumallowabletorqueis200Nmwithspeedsupto1050rad/s.Aseparatehydraulicunitisusedtoprovidetherequiredflowandpressurefortheclampingforces.Figure4givesaschematicoverviewoftheexperimentalsetup.

4.Experimentalresults

ThegeometricratiooftheCVTwasfixedduringtheexperimentsusingaso-calledratioringandthelimitsoftheprimarypulley.Thisratioringlimitthemovementofthepulley.Primaryandsecondarypressurewasheldconstant(clampingforceswereheldconstant)duringtheexperiments.

Figure4.Experimentalsetup

4.1Tractioncoefficient

Thetractioncoefficientwasmeasuredatdifferentratios,atdifferentprimaryspeedsandatdifferentpressures.Infigure6and7canbeseenthatthetractioncoefficientdependslittleonprimaryspeedorsecondaryclampingpressure,butmostlyonthetransmissionratio,ascanbeseeninfigure5.Anincreaseinclampingforcecausesmoreslip(seefigure8).Thisiscausedbyanincreaseintensioninthebandsandthereforeinanincreaseinlengthofthebelt.Thiscausestheplaytoincrease.

Figure5.Tractioncoefficientat300rad/s,ratiolow(0.4),Medium(1.1)andoverdrive(2.26)

4.2Efficiency

Theefficiencydependsonpressureandonratio.Fromfigure12canbeseenthatanincreaseinpressurecausesadecreaseinefficiency.Thiseffectiscausedbytheinternalfrictioninthebelt.Slipbetweentheblocksandthebandsalsocausesastrongdependencyonratio(seefigure9).Efficiencyisclearlyhigherinmediumthaninoverdriveorlow.Inmediumnoslipoccursbetweentheblocksandthebands,butinoverdriveorlowthebandsslipovertheblocks.Athighclampinglevelsthiseffectisgreater,becausethenormalforcesactingbetweentheblocksandthebandsincreaselinearlywithanincreaseinclampinglevel.Fromfigure10and11canbeseenthatinputspeedalsohasaninfluenceon