IPC TM650实验方法手册.docx

《IPC TM650实验方法手册.docx》由会员分享,可在线阅读,更多相关《IPC TM650实验方法手册.docx(21页珍藏版)》请在冰豆网上搜索。

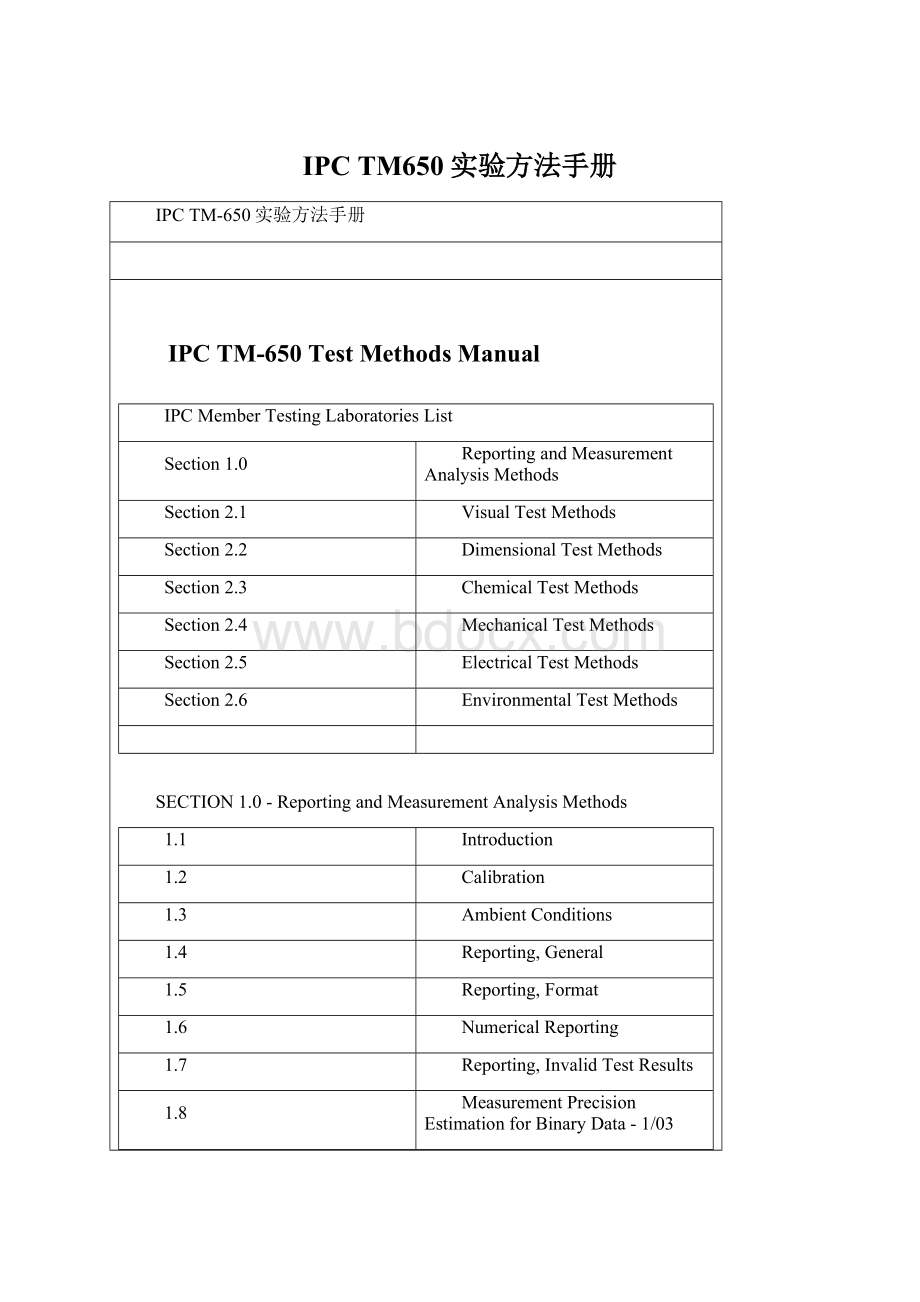

IPCTM650实验方法手册

IPCTM-650实验方法手册

IPCTM-650TestMethodsManual

IPCMemberTestingLaboratoriesList

Section1.0

ReportingandMeasurementAnalysisMethods

Section2.1

VisualTestMethods

Section2.2

DimensionalTestMethods

Section2.3

ChemicalTestMethods

Section2.4

MechanicalTestMethods

Section2.5

ElectricalTestMethods

Section2.6

EnvironmentalTestMethods

SECTION1.0-ReportingandMeasurementAnalysisMethods

1.1

Introduction

1.2

Calibration

1.3

AmbientConditions

1.4

Reporting,General

1.5

Reporting,Format

1.6

NumericalReporting

1.7

Reporting,InvalidTestResults

1.8

MeasurementPrecisionEstimationforBinaryData-1/03

MeasurementPrecisionCalculator-BinaryData

MeasurementPrecisionCalculatorUsersGuide

(forusewithtestmethod1.8)

1.9

MeasurementPrecisionEstimationforVariablesData-1/03

MeasurementPrecisionCalculator-VariableData

MeasurementPrecisionCalculatorUsersGuide

(forusewithtestmethod1.9)

SECTION2.1-VISUALTESTMETHODS

2.1.1D

Microsectioning-3/98

2.1.1.1

Microsectioning,CeramicSubstrate-12/87

2.1.1.2

Microsectioning-SemiorAutomaticTechniqueMicrosectionEquipment(Alternate)-7/93

2.1.2A

PinholeEvaluation,DyePenetrationMethod-3/76

2.1.3A

Plated-ThroughHoleStructureEvaluation-8/76

2.1.5A

SurfaceExamination,UncladandMetalCladMaterial-12/82

2.1.6B

ThicknessofGlassFabric-12/94

2.1.6.1

WeightofFabricReinforcements-12/94

2.1.7C

ThreadCountofGlassFabric-12/94

2.1.7.1

ThreadCount,OrganicFibers-12/87

2.1.8B

Workmanship-12/94

2.1.9

SurfaceScratchExaminationMetalCladFoil-5/86

2.1.10A

VisualInspectionforUndissolvedDicyandiamide-12/94

2.1.13A

InspectionforInclusionsandVoidsinFlexiblePrintedWiringMaterials-5/98

SECTION2.2-DIMENSIONALTESTMETHODS

2.2.1A

MechanicalDimensionalVerification-8/97

2.2.2B

OpticalDimensionalVerification-8/97

2.2.4C

DimensionalStability,FlexibleDielectricMaterials-5/98

2.2.5A

DimensionalInspectionsUsingMircosections-8/97

2.2.6A

HoleSizeMeasurement,Drilled-8/97

2.2.7A

HoleSizeMeasurement,Plated-5/86

2.2.8

LocationofHoles-4/73

2.2.10A

HoleLocationandConductorLocation-12/83

2.2.12A

ThicknessofCopperbyWeight-3/76

2.2.12.1

OverallThicknessandProfileFactorofCopperFoils

TreatedandUntreated-9/87

2.2.12.2

WeightandThicknessofCopperFoils

withReleasableCarriers-7/89

2.2.12.3

WeightandThicknessDeterminationofCopperFoils

WithEtchableCarriers-7/89

2.2.13.1A

Thickness,PlatinginHoles,MicrohmMethod-1/83

2.2.14

SolderPowderParticleSizeDistribution

-ScreenMethodforTypes1-4-1/95

2.2.14.1

SolderPowderParticleSizeDistribution

-MeasuringMicroscopeMethod-1/95

2.2.14.2

SolderPowderParticleSizeDistribution-OpticalImageAnalyzerMethod--1/95

2.2.14.3

DeterminationofMaximumSolderPowderParticleSize-1/95

2.2.15

CableDimensions(FlatCable)-6/79

2.2.16

ArtworkMasterEvaluationbyUseofaDrilledPanel-12/87

2.2.16.1

ArtworkMasterEvaluationbyOverlay-12/87

2.2.17

SurfaceRoughnessandProfileofMetallicFoils

(ContactingStylusTechnique)-3/90

2.2.17A

SurfaceRoughnessandProfileofMetallicFoils

(ContactingStylusTechnique)-2/01

2.2.18

DeterminationofThicknessofLaminatesby

MechanicalMeasurement-12/94

2.2.18.1

DeterminationofThicknessofMetallicCladLaminates,

Cross-sectional-12/94

2.2.19

MeasuringHolePatternLocation-12/87

2.2.19.1

Length,WidthandPerpendicularityofLaminateandPrepregPanels-12/94

2.2.20

SolderPasteMetalContentbyWeight-1/95

2.2.21

PlanarityofDielectricsforHighDensityInterconnection(HDI)MicroviaTechnology-11-98

SECTION2.3-CHEMICALTESTMETHODS

2.3.1

ChemicalProcessing,SuitableProcessingMaterial-4/73

2.3.1.1B

ChemicalCleaningofMetalCladLaminates-5/86

2.3.2F

ChemicalResistanceOfFlexiblePrintedWiringMaterials-5/98

2.3.3A

ChemicalResistanceofInsulatingMaterials-2/78

2.3.4B

ChemicalResistance,MarkingPaintsandInks-8/97

2.3.4.2A

ChemicalResistanceofLaminates,PrepregandCoatedFoilProducts,bySolventExposure-12/94

2.3.4.3

ChemicalResistanceofCoreMaterialstoMethyleneChloride-5/86

2.3.5B

Density,InsulatingMaterial-8/97

2.3.6A

Etching,AmmoniumPersulfateMethod-7/75

2.3.7A

Etching,FerricChlorideMethod-7/75

2.3.7.1A

CupricChlorideEtchingMethod-12/94

2.3.7.2A

AlkalineEtchingMethod-12/94

2.3.8A

Flammability,FlexibleInsulatingMaterials-12/82

2.3.8.1

FlammabilityofFlexiblePrintedWiring-12/88

2.3.9D

FlammabilityofPrepregandThinLaminate-8/97

2.3.10B

FlammabilityofLaminate-12/94

2.3.10.1

FlammabilityofSoldermaskonPrintedWiringLaminate-8/98

2.3.11

GlassFabricConstruction-4/73

2.3.13

DeterminationofAcidValueofLiquidSolderFlux-PotentiometricandVisualTitrationMethods-1/95

2.3.14

Print,Etch,andPlateTest-4/73

2.3.15C

Purity,CopperFoilorPlating-8/97

2.3.16B

ResinContentofPrepreg,byBurn-off-12/94

2.3.16.1C

ResinContentofPrepeg,byTreatedWeight--12/94

2.3.16.2

TreatedWeightofPrepreg-12/94

2.3.17D

ResinFlowPercentofPrepreg-8/97

2.3.17.1B

ResinFlowofAdhesiveCoatedFilmsandUnsupportedAdhesiveFilms-5/98

2.3.17.2B

ResinFlowof"NoFlow"Prepreg-8/97

2.3.18A

GelTime,PrepregMaterials-4/86

2.3.19C

VolatileContentofPrepreg-12/94

2.3.21

PlatingQuality,HullCellMethod-8/97

2.3.22

CopperProtectiveCoatingQuality-2-78

2.3.23B

Cure(Permanency)ThermallyCuredSolderMask-2/88

2.3.23.1A

Cure(Permanency)UVInitiatedDryFilmSolderMask-2/88

2.3.24

PorosityofGoldPlating-2/78

2.3.24.1

PorosityTestingofGoldElectrodepositedonaNickelPlatedCopperSubstrateElectrographicMethod-10/85

2.3.24.2A

PorosityofMetallicCoatingsonCopper-BasedAlloysandNickel(NitricAcidVaporTest)-8/97

2.3.25B

DetectionandMeasurementofIonizableSurfaceContaminants-8/97---Supersedes2.3.26and2.3.26.1

2.3.25C

DetectionandMeasurementofIonizableSurfaceContaminantsbyResistivityofSolventExtract-2/01

2.3.25.1

IonicCleanlinessTestingofBarePWBs

2.3.26A

SupersededbyTestMethod2.3.25

2.3.26.1

SupersededbyTestMethod2.3.25

2.3.26.2

MobileIonContentofPolymerFilms-7/95

2.3.27

CleanlinessTest-ResidualRosin-1/95

2.3.27.1

RosinFluxResidueAnalysis-HPLCMethod-1/95

2.3.28

IonicAnalysisofCircuitBoards,IonChromatographyMethod-1/95

2.3.29

Flammability,FlexibleFlatCable-11/88

2.3.30A

SolventpHDeterminationinAnhydrousFlourocarbonSolvents-11/81

2.3.31

RelativeDegreeofCureofU.V.CurableMaterial-2/88

2.3.32C

FluxInducedCorrosion(CopperMirrorMethod)-1/95

2.3.33C

PresenceofHalidesinFlux,SilverChromateMethod-1/95

2.3.34B

SolidsContent,Flux-1/95

2.3.34.1B

PercentageofFluxon/inFlux-Coatedand/orFlux-CoredSolder-1/95

2.3.35B

HalideContent,Quantitative(ChlorideandBromide)-1/95

2.3.35.1

FluoridesbySpotTest,Fluxes-Qualitative-1/95

2.3.35.2

FlourideConcentration,Fluxes-Quantitative--1/95

2.3.36

AcidAcceptanceofChlorinatedSolvents-10/85

2.3.37B

VolatileContentofAdhesiveCoatedDielectricFilms-5/98

2.3.38B

SurfaceOrganicContaminantDetectionTest-8/97

2.3.39B

SurfaceOrganicContaminantIdentificationTest(InfraredAnalyticalMethod)-8/97

2.3.40

ThermalStability-7/95

SECTION2.4-MECHANICALTESTMETHODS

2.4.1D

Adhesion,TapeTesting--8/97

2.4.1.1B

Adhesion,MarkingPaintsandInks--11/88

2.4.1.2

AdhesionofConductorsonHybridSubstrates--12/87

2.4.1.3

Adhesion,Resistors(HybridCircuits)--12/87

2.4.1.4

Adhesion,Overglaze(HybridCircuits)--12/87

2.4.1.5A

DeterminationofHeatTransfer--5/95

2.4.1.6

Adhesion,PolymerCoating--7/95

2.4.2A

DuctilityofCopperFoil--3/76

2.4.2.1D

FlexuralFatigueandDuctility,Foil--3/91

2.4.3D

FlexuralFatigue,FlexiblePrintedWiringMaterials--5/98

2.4.3.1C

FlexuralFatigueandDuctility,FlexiblePrintedWiring--3/91

2.4.3.2C

FlexuralFatigueandDuctility,FlexibleMetal-CladDielectrics--3/91

2.4.4B

FlexuralStrengthofLaminates(atAmbient Temperature)--12/94

2.4.4.1A

FlexuralStrengthofLaminates(atElevatedTemperature)--12/94

2.4.5

FoldingEndurance,FlexiblePrintedWiringMaterials--4/73

2.4.5.1

Flexibility-ConformalCoating

2.4.6

HotOil--4/73

2.4.7A

Machinability,PrintedWiringMaterials--7/75

2.4.8C

PeelStrengthofMetallicCladLaminates--12/94

2.4.8.1

PeelStrength,MetalFoil(KeyholeMethodforThinLaminates)--1/86

2.4.8.2A

PeelStrengthofMetallicCladLaminatesatElevatedTemperature(HotFluidMethod)--12/94

2.4.8.3A

PeelStrengthofMetallicCladLaminatesatElevatedTemperature(HotAirMethod)--12/94

2.4.8.4

CarrierRelease,ThinCopper--1/90

2.4.9D

PeelStrength,FlexibleDielectricMaterials--10/88

2.4.9.1

PeelStrengthofFlexibleCircuits-11/98

2.4.9.2

BondingProcess-11/98

2.4.10

PlatingAdhesion--4/73

2.4.11

ShearStrengthFlexibleDielectricMaterials--4/73

2.4.12A

Solderability,EdgeDipMethod--6/91

2.4.13F

SolderFloatResistanceFlexiblePrintedWiringMaterials--5/98

2.4.13.1

ThermalStressofLaminates--12/94

2.4.14

SolderabilityofMetallicSurfaces--4/73

2.4.14.1

Solderability,WaveSolderMethod--3/79

2.4.14.2

LiquidFluxActivity,WettingBalanceMethod--1/95

2.4.15A

SurfaceFinish,MetalFoil--3/76

2.4.16A

InitiationTearStrength,FlexibleInsulatingMaterials--12/82

2.4.17

TearStrength,Propagation--4/73

2.4.17.1A

Propagation,TearStrength,FlexibleInsulatingMaterials--12/82

2.4.18B

TensileStrengthandElongation,CopperFoil--8/80

2.4.18.1

TensileStrengthan