STPYZ105-00SW-CJ-2FD型净化工作台验证方案.doc

《STPYZ105-00SW-CJ-2FD型净化工作台验证方案.doc》由会员分享,可在线阅读,更多相关《STPYZ105-00SW-CJ-2FD型净化工作台验证方案.doc(7页珍藏版)》请在冰豆网上搜索。

大连昆阳制药有限公司 STP/YZ105-00 第7页共6页

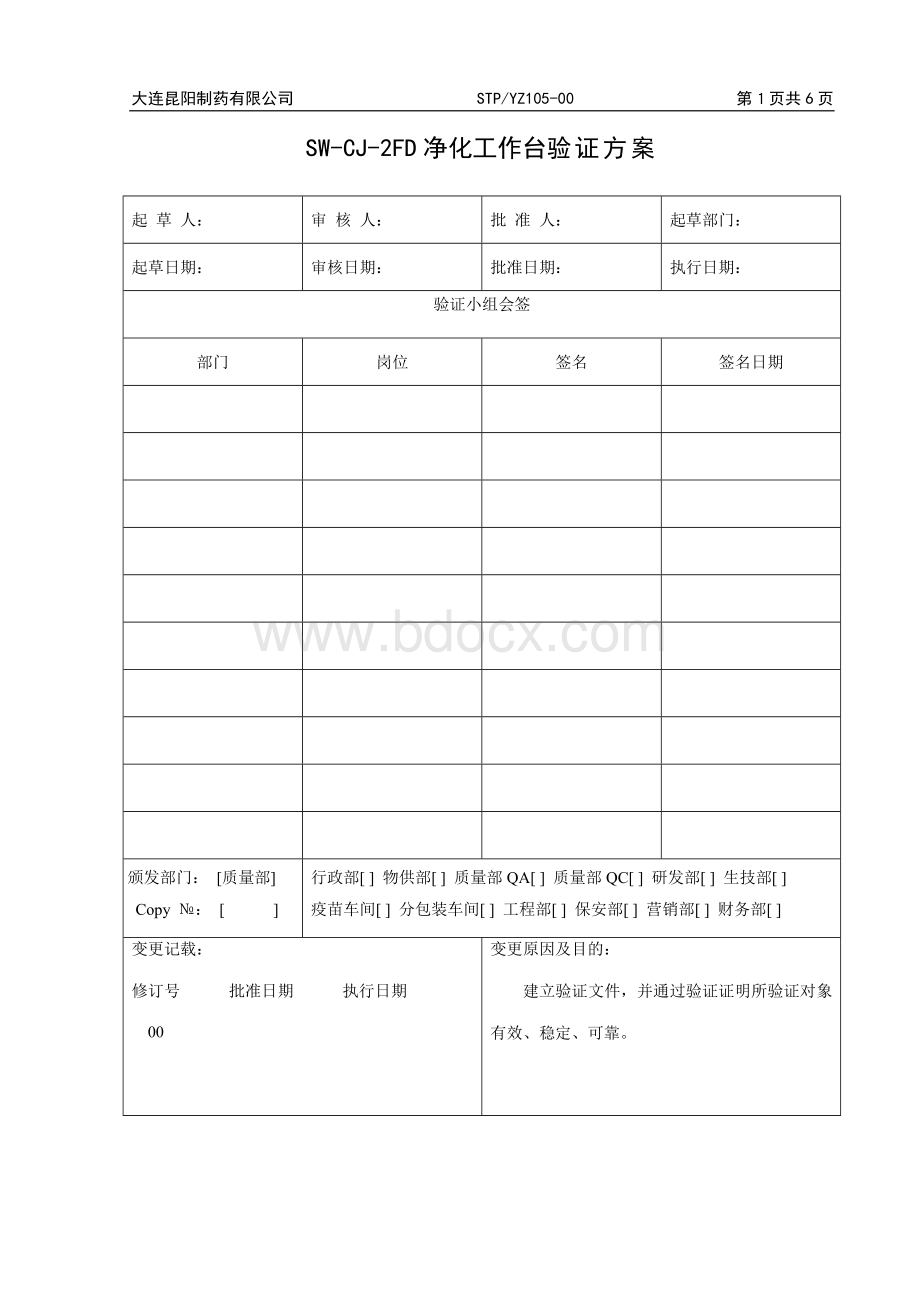

SW-CJ-2FD净化工作台验证方案

起草人:

审核人:

批准人:

起草部门:

起草日期:

审核日期:

批准日期:

执行日期:

验证小组会签

部门

岗位

签名

签名日期

颁发部门:

[质量部]

Copy№:

[]

行政部[]物供部[]质量部QA[]质量部QC[]研发部[]生技部[]

疫苗车间[]分包装车间[]工程部[]保安部[]营销部[]财务部[]

变更记载:

修订号批准日期执行日期

00

变更原因及目的:

建立验证文件,并通过验证证明所验证对象有效、稳定、可靠。

目录

验证方案·····································································································································3

1概述···································································································································3

2目的···································································································································3

3职责···································································································································3

4内容···································································································································3

4.1预确认·······················································································································3

4.2安装确认·······························································································3

4.3运行确认···················································································································3

4.4性能确认···················································································································3

4.4.1目的·······················································································································4

4.4.2可接受标准···········································································································4

4.4.3静态尘埃粒子检测·······························································································4

4.4.4静态沉降菌检测···································································································4

5日常监控···························································································································4

附件1:

确认内容及可接受标准

附件2:

资料档案确认表

附件3:

安装确认记录表

附件4:

运行确认记录表

附件5:

静态尘埃粒子确认记录表

附件6:

静态沉降菌确认记录表

验证方案

1概述

净化工作台主要用于为试验提供百级试验环境,减少试验过程中微生物污染的机率,为试验检测数据的准确性提供重要的保障。

因此必须对净化工作台进行验证,以确保该设备能提供一个长期稳定的洁净环境,确保检验数据的真实可靠。

本方案规定了净化工作台的验证方案及接受标准,依据是净化工作台的使用说明书和《SW-CJ-2FD型净化工作台使用、维护保养标准操作规程》

2目的

对该设备进行验证,以确保该设备能提供稳定的洁净环境,确保检验数据的真实可靠。

3职责

质量部QC室:

负责起草质量部QC室净化工作台的验证方案,报告及验证实施。

工程部:

协助质量部进行净化工作台的验证实施。

验证小组:

负责验证方案的实施、验证方案与验证报告的审核会签。

验证管理员:

负责对验证过程进行协调检查。

QC检验员:

负责验证中的取样检验,测试检验数据,并出具准确的检验报告。

4验证内容

4.1预确认:

见附件1

4.2安装确认

4.2.1资料档案:

确认内容见附件2。

。

4.2.2安装确认:

确认内容见附件3。

4.2.3仪表检验尘埃粒子计数器由生产厂家进行校验。

4.3运行确认

4.3.1目的

4.3.1.1对标准操作规程的适用性进行确认。

4.3.1.2检查确认系统运转是否正常,并符合技术参数要求。

对操作规程的适用性进行确认。

4.3.1.3测试记录见附件4。

4.4性能确认

4.4.1目的

4.4.1.1检查确认系统运转是否正常,并符合技术参数要求,满足工作需要。

4.4.1.2对操作规程的适用性进行确认。

4.4.2可接受标准:

操作各控制器时,应灵活有效,洁净度应符合技术参数要求。

4.4.3静态尘埃粒子检测

4.4.3.1目的

考察设备运行时能否达到百级环境内尘埃粒子数的要求

4.4.3.2测试与方法:

4.4.3.2.1按《SW-CJ-2F型净化工作台使用、维护保养标准操作规程》进行操作,开启净化工作台通风30分钟。

4.4.3.2.2按《CLJ-BM型尘埃粒子计数器使用、维护保养标准操作规程》进行操作,将仪器自净20分钟后进行检测。

4.4.3.2.3取净化工作台左、中、右三个点进行检测,每个点打印数据三次(见附件5)。

4.4.4静态沉降菌检测

4.4.4.1目的

考察设备运行时能否达到百级环境沉降菌数≤1/皿的要求

4.4.4.2测试与方法:

4.4.4.2.1按《SW-CJ-2F型净化工作台使用、维护保养标准操作规程》进行操作,开启净化工作台通风30分钟。

4.4.4.2.2将已预孵合格的φ90mm琼脂平皿五个分别放置在净化工作台上两个、中一个、下两个,打开平皿盖子,暴露30分钟后盖上盖子,将平皿放入35~37℃恒温培养箱中培养48小时,记录菌落数(见附件6)。

5日常监控

(1)在日常运行中要经常检查设备的运行状况。

(2)日常监控:

QC人员每个月监测。

(3)正常情况下系统每年做一次验证。

附件1:

确认内容及可接受标准

确认内容

可接受标准

确认结果

确认人

电源电压

220V50Hz

尘埃粒子数(0.5μm)

≤3500个/m3

尘埃粒子数(5μm)

≤0个/m3

沉降菌数

≤1

平均风速

0.35M/S±20%

结论:

实施人:

日期:

审核人:

日期:

附件2:

资料档案确认表

确认内容

存放处

确认结果

确认人

使用说明书

产品合格证

结论:

实施人:

日期:

审核人:

日期:

附件3:

安装确认记录表

确认内容

接受标准

确认结果

确认人

主机外观

无损伤,表面喷涂处理或为不锈钢材料

安装位置

SW-CJ-2FD无菌检查室

环境要求

万级洁净室内,地面应平整

结论:

实施人:

日期:

审核人:

日期:

附件4:

运行确认记录表(无菌检查室)

确认内容

接受标准

确认结果

确认人

标准操作规程适用性

适用

仪器运转情况

正常

结论:

实施人:

日期:

审核人:

日期:

附件5:

静态尘埃粒子确认记录表(无菌检查室)

确认内容

可接受标准

确认结果

确认人

左侧

≤3500个/m3(0.5μm)

≤0个/m3(5μm)

中部

≤3500个/m3(0.5μm)

≤0个/m3(5μm)

右侧

≤3500个/m3(0.5μm)

≤0个/m3(5μm)

结论:

实施人:

日期:

审核人:

日期:

附件6:

静态沉降菌确认记录表(无菌检查室)

确认内容

可接受标准

确认结果

确认人

1

≤

2

≤

3

≤

4

5

结论:

实施人:

日期:

审核人:

日期: