PCB英语.docx

《PCB英语.docx》由会员分享,可在线阅读,更多相关《PCB英语.docx(25页珍藏版)》请在冰豆网上搜索。

PCB英语

AnembeddedsystemisundoubtedlythemostpopularoneofthemostpromisingfieldofITapplications.Embeddedsystemsusedincertainspecialequipment,thesedevicesusuallyhardwareresources(suchasCPU,memory,etc.)isverylimited,andthecostisverysensitive,sometimestothereal-timeresponserequirementsarehigher.Especiallytheintelligentasconsumerappliances,embeddedmoreimportant.Likeweusuallyseemobilephone,PDA,electronicdictionary,visualtelephone,VCD/DVD/MP3Player,digitalcamera(DC),digitalvideocamera(DV),UDisk,STB(SetTopBox),high-definitiontelevision(HDTV),gameconsoles,smarttoys,switches,routers,ncequipmentorinstrumentation,automotiveelectronics,homeappliances,medicalequipment,aerospaceequipment,controlsystemandsoon

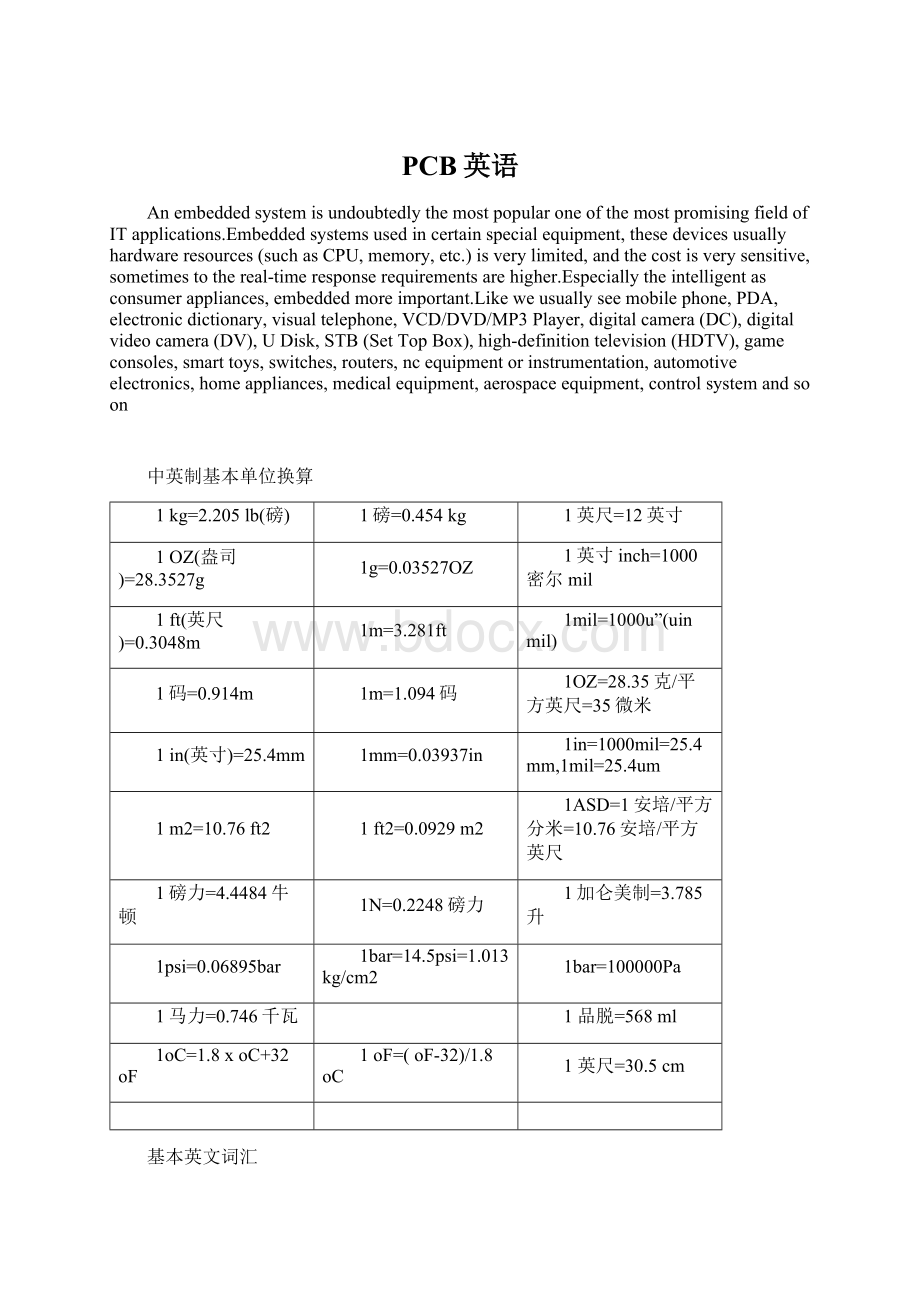

中英制基本单位换算

1kg=2.205lb(磅)

1磅=0.454kg

1英尺=12英寸

1OZ(盎司)=28.3527g

1g=0.03527OZ

1英寸inch=1000密尔mil

1ft(英尺)=0.3048m

1m=3.281ft

1mil=1000u”(uinmil)

1码=0.914m

1m=1.094码

1OZ=28.35克/平方英尺=35微米

1in(英寸)=25.4mm

1mm=0.03937in

1in=1000mil=25.4mm,1mil=25.4um

1m2=10.76ft2

1ft2=0.0929m2

1ASD=1安培/平方分米=10.76安培/平方英尺

1磅力=4.4484牛顿

1N=0.2248磅力

1加仑美制=3.785升

1psi=0.06895bar

1bar=14.5psi=1.013kg/cm2

1bar=100000Pa

1马力=0.746千瓦

1品脱=568ml

1oC=1.8xoC+32oF

1oF=(oF-32)/1.8oC

1英尺=30.5cm

基本英文词汇

流程

Boardcut开料Carbonprinting碳油印刷

Innerdryfilm内层干膜Peelablebluemask蓝胶

Inneretching内层蚀刻

ENIG(Electrolessnickelimmersiongold)沉镍金

Innerdryfilmstripping内层干膜退膜HAL(hotairleveling)喷锡

AOI(AutomaticOpticalInspection)自动光学检测

OSP(Organicsolderabilitypreservative)有机保焊

Pressing压板Punching啤板

Drilling钻孔Profiling外形加工

Desmear除胶渣,去钻污E-Test电性测试

PTH镀通孔,沉铜FQC(finalqualitycontrol)最终品质控制

Panelplating整板电镀FQA(Finalqualityaudit)最终品质保证

Outerdryfilm外层干膜Packing包装

Etching蚀刻IPQA(In-processqualityaudit)流程QA

Tinstripping退锡IPQC(In-processqualitycontrol)流程QC

EQC(QCafteretching)蚀检QC

IQC(Incomingqualitycontrol)来料检查

Soldermask感阻MRB(materialreviewboard)材料评审委员会

Componentmark字符QA(Qualityassurance)品质保证

PhysicalLaboratory物理实验室QC(Qualitycontrol)品质控制

ChemistryLaboratory化学实验室Documentcontrolcenter文件控制中心

2ndDrilling二钻Routing锣板,铣板

Brownoxidation棕化Wastewatertreatment污水处理

V-cutV坑WIP(workinprocess)半成品

Store/stock仓库F.G(Finishedgoods)成品

概述

PrintedCircuitBoard印制电路板FlexiblePrintedCircuit,FPC 软板

Double-SidePrintedBoard双面板

IPC(TheInstituteforInterconnectingandPackingElectronicCircuits)电子电路互连与封装协会

CPAR(Corrective&PreventiveActionRequest)要求纠正预防措施

FlammabilityRate燃性等级Characteristicimpedance特性阻抗

BUM(Build-upmultilayer)积层多层板DateCode周期代码

CCL(Copper-cladlaminate)覆铜板Ioniccontamination 离子性污染

AcceptanceQualityLevel(AQL)允收水平

HDI(Highdensityinterconnecting)高密度互连板

BaseMaterial基材Radius半径

Capacity生产能力Diameter直径

Capability工艺能力PPM(PartsPerMillion)百万分之几

CAM(computer-aidedmanufacturing)计算机辅助制造

UnderwritersLaboratoriesInc.美国保险商实验所

CAD(computer-aideddesign)计算机辅助设计

StatisticalProcessControl统计过程控制

Specification规格,规范Via导通孔

Dimension尺寸Buried/blindvia埋/盲孔

Tolerance公差Toolinghole定位孔

Oven焗炉Output/throughput产量

湿流程

PTH(platedthroughhole)镀通孔(俗称沉铜)Acidcleaning酸性除油

PP(PanelPlating)板电Aciddip酸洗

Patternplating图电Pre-dip预浸

Linewidth线宽Alkalinecleaning碱性除油

Spacing线隙Flux松香

Deburring去毛刺(沉铜前磨板)Hotairleveling喷锡

Carbontreatment碳处理Skipplating跳镀,漏镀

Track/conductor导线Undercut侧蚀

Aspectratio深径比Waterrinsing水洗

EtchFactor蚀刻因子Transportation行车

BackLightTest背光测试Rack挂架

Pinkring粉红圈Maintenance保养

干流程

Holelocation孔位Annularring孔环

ImageTransfer图象转移ComponentSide(C/S)元件面

Artwork底片SolderSide(S/S)焊接面

Mylar胶片MatteSolderMask哑绿油

Silkscreen/legend/ComponentMark文字Holebreakout 破孔

Fiducialmark基点,对光点Scrubbing磨板

Expose曝光Developing显影

内层制作

Corematerial内层芯板Thermalpad散热PAD

Pre-pregPP片Resincontent树脂含量

KraftPaper牛皮纸Brownoxidation棕化

Layup排版BlackOxidation黑化

Registration对位Basematerial板材

Delamination分层

其它

Wicking灯芯效应Holesize孔径(尺寸)

Yield良品率TouchUp修理

WarpandTwist板曲度SolventTest溶剂测试

Peeloff剥离CompanyLogo公司标识

TapeTest胶纸试验ULMarkUL标记

Cosmetic外观Function功能

Tin/LeadRatio锡/铅比例ReliabilityTests可靠性试验

HoleWallRoughness孔壁粗糙度BaseCopperThickness底铜厚度

PCB专业英语(PCBSPECIALENGLISH)

1.PCB=PrintedCircuitBoard电路板

2.CAM=Computeraidedmanufacture计算机辅助

3.Pad焊盘

4.Annularring焊环

5.AOI=automaticopticalinspection自动光学检测

6.Chargeoffree免费

7.WIP=workinprocess在线板

8.DCC=documentcontrolcenter文控中心

9.Legend字符

10.CS=ComponentSide=TopSide(顶层)元件面

11.SS=SolderSide=BottomSide(底层)焊锡面

12.GoldPlated电金,镀金

13.NickelPlated电镍,镀镍

14.ImmersionGold沉金=沉镍金

15.CarbonInkPrint印碳油

16.MicrosectionReport切片报告,横切面报告

17.X-out=Cross-out打"X"报告

18.Panel(客户称)拼板,(生产线称)工作板

19.Marking标记,UL标记

20.Datecode生产周期

21.Unit单元,单位

2