Coulometric Thickness Tester DJHE.docx

《Coulometric Thickness Tester DJHE.docx》由会员分享,可在线阅读,更多相关《Coulometric Thickness Tester DJHE.docx(16页珍藏版)》请在冰豆网上搜索。

CoulometricThicknessTesterDJHE

CoulometricThicknessTester

DJH-E

Instruction

Pleasereadthismanualcarefullybeforeusingthetester

DECLARE:

1.Theinformationofthecopyright

©2000,COATTEST

Copyright:

don’tcopy,useortranslateuntilpermittedtoCOATTEST

2.Declaretotheinformationguarantee

Theinformationcontainedinthisinstructionmayberevisedtimely,andwillnotinformyouagain.

COATTESTisnotresponsibleforthemeasurementerrorsresultingfromoperations,whichdonotconformtothisinstruction.

3.ThemeasurabletypesoftheplatingforthemodelDJH-EElectrolysisthickness-tester:

Au,Ag,Sn,Zn,Cu,Ni,andCr

Iftheconsumerrequiresincreasingmeasurementtypesoftheplating,pleasecontactwithCOATTEST

4.Caution:

Foryoursafety,pleasedon’topenthecoverofthetesterbyyourselfinordertoavoidaccidents.

Controlledinformation

Theinstructionisonlyprovidedwithlegalconsumers;don’tplagiarize,copyorpropagatethefullorsomecontentsoftheinstructionwithoutourpermission.Wewillneverpardonanytorttothisinstruction,evenresorttothelaw.

Weexpecttheconsumertocarefullyoperatetoassureself-legalrightsandinterests.

CONTENTS

ØFeatures……………………………………………………………………………………1

ØPrecaution………………………………………………………………………………….2

ØNomenclatureofprincipalpartsandcontrols……………………………………...3

ØNomenclatureofMeasuringStand……………………………………………………4

ØPre-checkbeforemeasurement…………………………………………………………5

ØHowtoselecttheelectrolyticsolutions……………………………………………....6

ØHowtomeasuretheplatingmetalofsinglelayer……………………………….….7

ØHowtomeasurethehardchromiumplating………………………………………..8

ØHowtomeasurethemulti-layerplating…………………………………………9~10

ØSolutioncomponentsandmethod

ØTimesetandtroubleshooting………………………………………………………13

ØSpecificationandstatement……………………………………………………...14

ØMaintenanceandsupport……………………………………………………………….15

FEATURES

☑Abletomeasuresinglemetallayer

☑Abletomeasuremulti-metallayer

☑Abletomeasuremetalcoatingsonplastics

☑Measurementisnotinfluencedbythesubstrate

☑LEDdisplay;printreportsdirectly

1

PRECAUTION

1.Avoidtemperaturechange

Whenmovedsuddenlyfromcoldtowarmplace,thetesterwillcausemeasurementuncertainty

2.Moistanddust

Avoidusingthistesterwherethereismuchmoistanddust,otherwise,theinnerpartsmaybedamaged

3.Avoidtoohighortoolowtemperature

Thetesterandsolutionsshouldavoiddirectsunlightandheatradiator.

Thetemperatureshouldbebelow30centigrade.Thegasketsmay

becomesoftbecauseoflowtemperature

4.Keeptheelectrode,electrolysiscellandgasketclean

Thescrewsandclipscontaminationmayinfluenceperformance.Theelectrolysiscellandgasketsubjectedtocontaminationwillleadtomeasurementerrors.

5.Avoidusingtheelectrolyticsolutionswhentemperatureistoolow

Avoidusingtheelectrolyticsolutionslowerthan10℃,somesolutionslikeA4,E4,A10,A12maycrystallizeandneedtoheatbeforeuse

6.Howtocleanthetester

Wipewithcleanandsoftcloth;don’tusecleaningliquidorotherchemicals,sprayingcleaneretc.

7.Don’tpilethingsonthetester

Thistestershouldbeplacedinevenandstraightplace,don’tstackotherthingsonit.

8.Thenormaltemperature

Pleaseusethistesterwithin20±5℃ofroomtemperature.

2

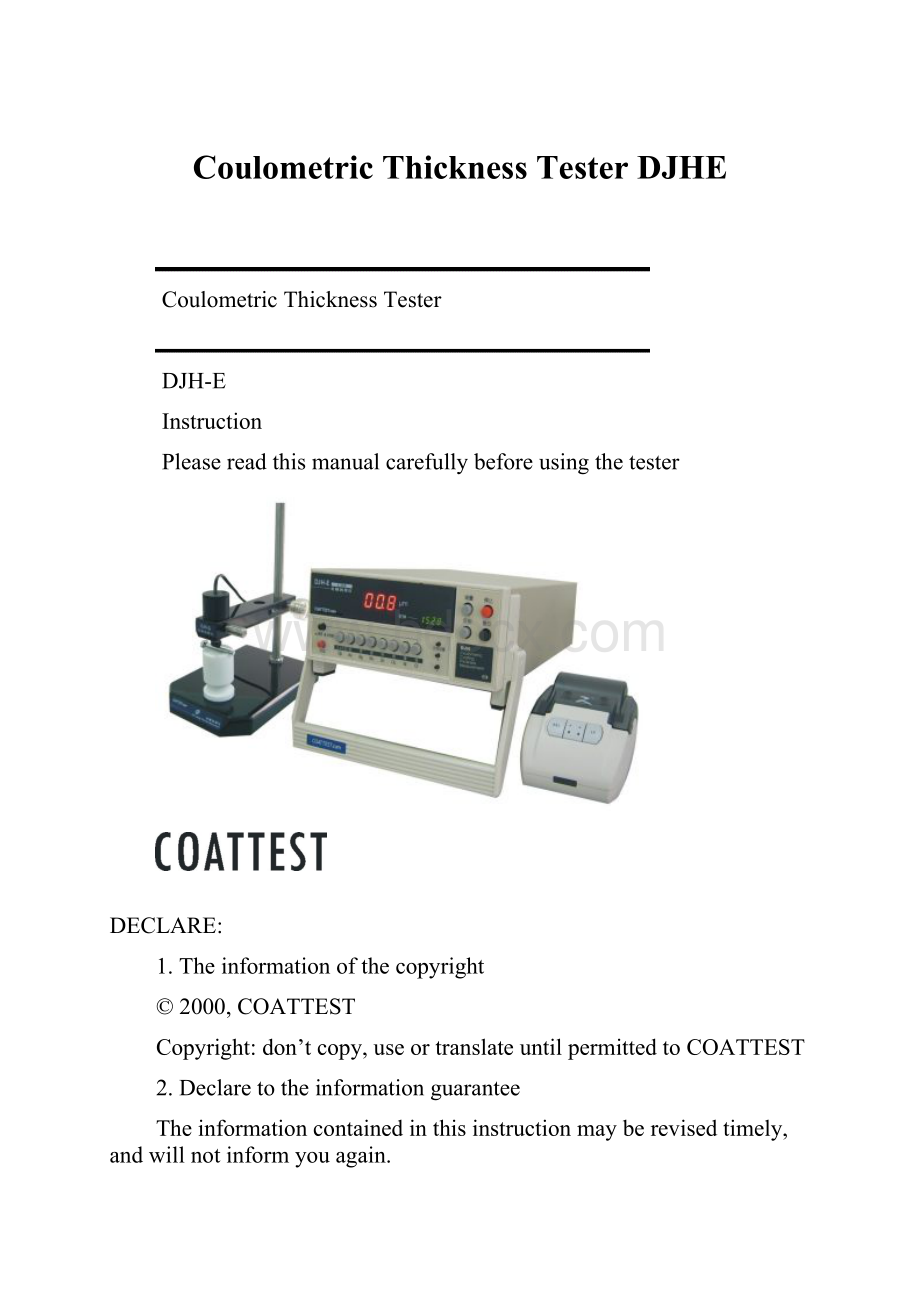

NOMENCLATUREOFPRINCIPALPARTSANDCONTROLS

Thicknessindicator

Measurementbutton

Useless

Useless

ACinputsocketandfuse

LED

Powerswitch

Cell

Stirringspeed-

adjustingknob

Outletofprintpaper

Clocksetbutton

Lidofpaperbox

SEL

LF

Printerinput

Powerswitch

Printeroutput

PlatingofCrselect

button

Printbutton

Decreasingbutton

Increasingbutton

Resetbutton

Reversebutton

Stopbutton

Metalselectbuttons

Bracket

3

NOMENCLATUREOFMEASURINGSTAND

4

pre-checkbeforemeasurement

1.Placethetester,testingstandandthestandofthechemicalsontheworkingdeskinevenandstraight.

2.BesurethatthepowersupplyisAC220V.

3.connectthetesterwithteststandandprinterbycables

4.Pressanyselectplatingbutton,shortoutthesignalcliptotheterminalofsignalplug,turnonthepowerswitchandthenpressthemeasurementbutton,thestirrershouldrotateandthedisplayedbegintocount.Disconnecttheconnectinglinebetweenthesignalclipandtheterminalofsignalplug,thetestershouldimmediatelystoptocountandalarm.Theconditionofthetestercanbeconsideredasnormal.

5.Iftheprinterison,aftertheprocedure4,pressPRINTbutton,andCOAT,THICK,andTIMEwilldisplay

5

Howtoselecttheelectrolyticsolutions

Designationofelectrolyticsolutionsanddepositedmetalandbasecombinations

Plating

metals

Base

Steel

Copperanditsalloys

Aluminum

Nickel

Multi-layer

nickel

NdFeB

Gold(Au)

A1

A1

Silver(Ag)

A6

A7

A6

Tin(Sn)

A3

A3

A3

Zinc(Zn)

A8

A8

A8

A8

A8

A8

Copper

(Cu)

A4

A4

A4

A4

Nickel(Ni)

A5

A5

A10

Chromium

(Cr)

A2

A3

A2

A2

A2

6

Howtomeasuretheplatingmetalsofsinglelayer

Example:

Themeasurementofthezincplatingwithwhitepassivationonthesteelsubstrate,it’sthicknessis10μm.

1.Usetherubbertowipeawaythepassivationfilmsonthesurfaceofzincplatingofthesampletobemeasured.

2.Pressthetestingheadverticallyonthesurfaceofthesampletobemeasured(untilnosolutionleaks)

3.ElectrolyticsolutionA8isselectedfromtable2forthecombinationofzincplatingonsteelsubstrate.Thecellmustbefilledwith2mloftheelectrolyticsolutionbyusingadropper.Thecellwillnotbefilledfull.(Thesolutionlevelisabout3mmfromtheopeningofthecell)

4.Insertpipettetothebottomoftheelectrolysiscell,repeatsuckingseveraltimesinordertoremovetheairbubblefromcell,enablestheelectrolyticsolutiontocontactcompletelywiththezincplatingbeforeplacingthestirrer

5.PresstheZnbutton.

6.Insertthesignalplugintotheholeofthescrewoftheelectrode,attachtheredsignalcliptotheplatedobjectandmakesureconnectioniscorrect.

7.pressthemeasurementbutton,thestirrerbeginsrotating,whilethebuzzeralarms,themeasurementwillbestoppedautomatically,thethickness12.2μmhasbeendisplayedontheindicator,pressthestopbutton.

8.raisethestirrer,removethewastesolutionandthesample

9.Rinsethestirrer,cleanuptheusedelectrolyticsolutionbyusingthepipette,rinsethetestinghead,removethesample

10.whentheprinterison,afterprocedure9pressPRINTbuttonandCOAT,THICKwilldisplay

Note

WhenmeasuretheplatingofAuorCr(decoratechromium),depresstheTbuttonandtheAuorCrbuttonattheonetime.

7

Howtomeasurethehardchromiumplating

Example:

Themeasurementofthehardchromiumplatingonsteelsubstrate,thethicknessofthehardchromiumplatingis35μm.

1.Usetherubbertowipeawaythepassivationfilmsonthesurfaceofchromiumplatingofthearticletobemeasured.

2.Depressthetestingheadverticallyonthesurfaceofthearticletobemeasured,appliedanadequatepressureuntilwithoutanyleakage.

3.ElectrolyticsolutionA2isselectedfromtable2,thecellmustbefilledwith2mloftheelectrolyticsolutionbyusingadropper.Thecellwillnotbefilledfull.(Thesolutionlevelisabout3mmfromtheopeningofthecell)

4.Insertthepipetteintothebottomoftheelectrolysiscell.Repeatsuckseveraltimes,inordertoremovetheairbubblefromthecell,enablestheelectrolyticsolutiontocontactcompletelywiththechromiumplating.

Note:

Whenmeasuringthechromiumplatingplacingthestirrerisnotarequirement.

5.

DepresstheplatingofCrselectbuttonandtheCrmeasurementbutton.(theplatingofCrselectbutton:

---measurethedecoratechromium---measurethehardchromium)

6.Insertthesignalplugintotheholeofthescrewoftheelectrode,attachtheredsignalcliptotheplatedobjectandbesurethataproperconnectionhasbeendone.

7.pressthemeasurementbutton,thestirrerbeginrotating,whenthethicknessof15μmshowsontheindicatorpressthestopbuttonthenpresstheprintbutton(ifnotthetestercouldnotworknormally),renewtheelectrolyticsolution,againpressthemeasurementbutton.Renewaloftheelectrolyticsolutionshouldbemadeatfrequencyofeven15μmuntilbuzzing.Recordthethicknessofthehardchromiumplating.

8.Cleanuptheusedelectrolyticsolutionbyusingthepipette.Risethetestinghead.Removethearticle.

9.Cleanuptheinternalsurfaceofthecellandgasketbyrinsewaterandwiping.Besurethatthereisnotanyoxidationproductsonthembeforetheyarereplacedback.

8

Howtomeasurethemulti-layerplating

Example:

Themeasurementofthethicknessofthemulti-layerdepositsconsistingofcopper、nickelandchromiumplatingonthesteelsubstrate.Thethicknessofthecomponentlayersis0.4μmofchromium,14μmofnickel,10μmofcopper.

1.Usetherubbertowipeawaythepassivationfilmsonthesurfaceofplatingonthearticletobemeasured

2.Pressthetestingheadverticallyonthesurfaceofthearticletobemeasured,appliedanadequatepressureuntilwithoutanyleakage.

3.ElectrolyticsolutionA2isselectedfromtable2,thecellmustbefilledwith2mloftheelectrolyticsolutionbyusingadropper.Thecellwillnotbefilledfull.(Thesolutionlevelisabout3mmfromthecell)

4.Insertthepipetteintothebottomoftheelectrolysiscell.Repeatsuckingseveraltimes,inordertoremovetheairbubblefromthecell,maketheelectrolyticsolutioncontactcompletelywiththechromiumplating.

Note:

Whenmeasuringth