螺杆压缩机性能的计算吸入室中占主导地位外文文献翻译中英文翻译外文翻译.docx

《螺杆压缩机性能的计算吸入室中占主导地位外文文献翻译中英文翻译外文翻译.docx》由会员分享,可在线阅读,更多相关《螺杆压缩机性能的计算吸入室中占主导地位外文文献翻译中英文翻译外文翻译.docx(19页珍藏版)》请在冰豆网上搜索。

螺杆压缩机性能的计算吸入室中占主导地位外文文献翻译中英文翻译外文翻译

英文原文

3.1OneDimensionalMathematicalModel51

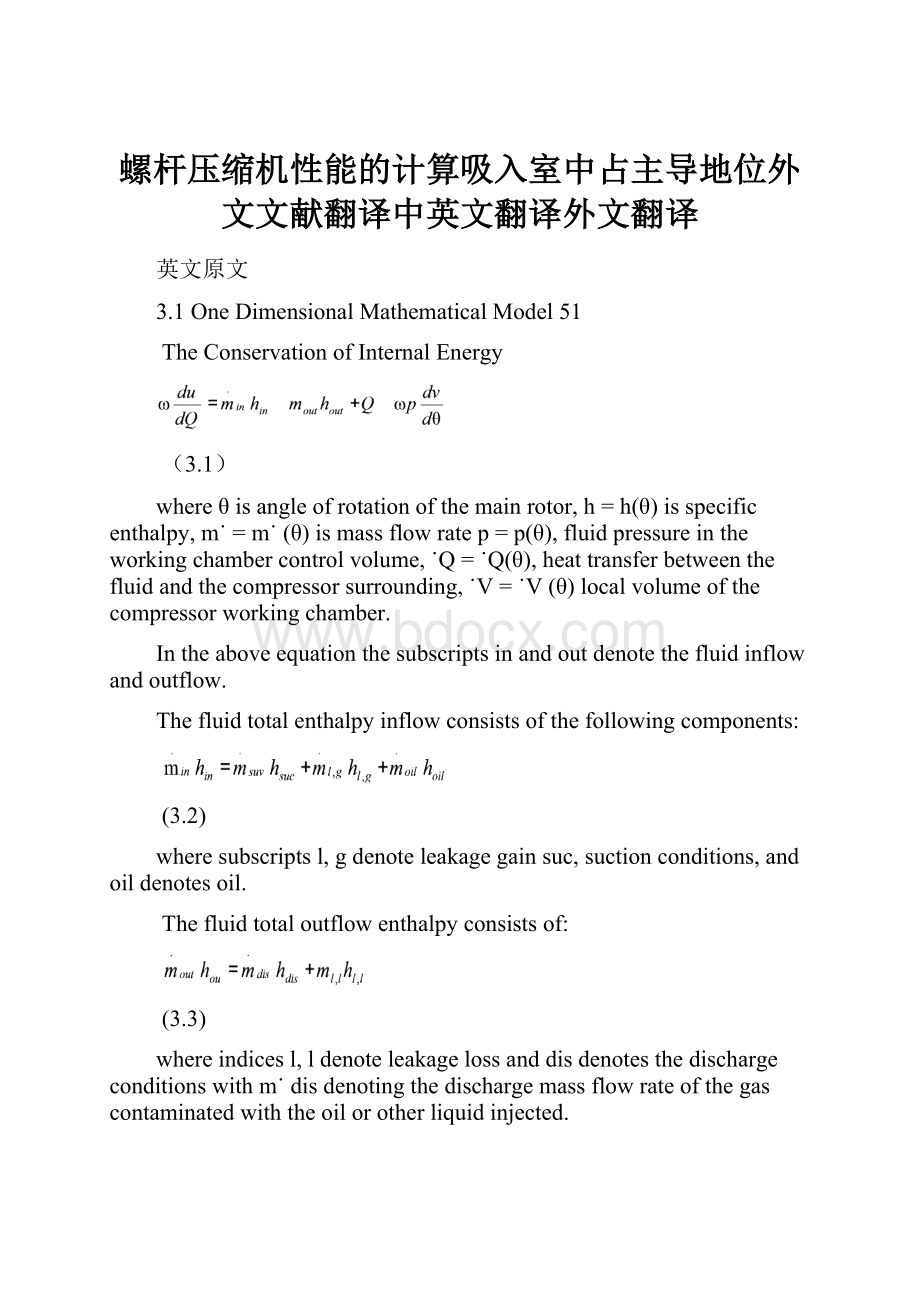

TheConservationofInternalEnergy

(3.1)

whereθisangleofrotationofthemainrotor,h=h(θ)isspecificenthalpy,m˙=m˙(θ)ismassflowratep=p(θ),fluidpressureintheworkingchambercontrolvolume,˙Q=˙Q(θ),heattransferbetweenthefluidandthecompressorsurrounding,˙V=˙V(θ)localvolumeofthecompressorworkingchamber.

Intheaboveequationthesubscriptsinandoutdenotethefluidinflowandoutflow.

Thefluidtotalenthalpyinflowconsistsofthefollowingcomponents:

(3.2)

wheresubscriptsl,gdenoteleakagegainsuc,suctionconditions,andoildenotesoil.

Thefluidtotaloutflowenthalpyconsistsof:

(3.3)

whereindicesl,ldenoteleakagelossanddisdenotesthedischargeconditionswithm˙disdenotingthedischargemassflowrateofthegascontaminatedwiththeoilorotherliquidinjected.

Therighthandsideoftheenergyequationconsistsofthefollowingtermswhicharemodel

Theheatexchangebetweenthefluidandthecompressorscrewrotorsandcasingandthroughthemtothesurrounding,duetothedifferenceintemperaturesofgasandthecasingandrotorsurfacesisaccountedforbytheheattransfercoefficientevaluatedfromtheexpressionNu=0.023Re0.8.ForthecharacteristiclengthintheReynoldsandNusseltnumberthedifferencebetweentheouterandinnerdiametersofthemainrotorwasadopted.Thismaynotbethemostappropriatedimensionforthispurpose,butthecharacteristiclengthappearsintheexpressionfortheheattransfercoefficientwiththeexponentof0.2andthereforehaslittleinfluenceaslongasitremainswithinthesameorderofmagnitudeasothercharacteristicdimensionsofthemachineandaslongasitcharacterizesthecompressorsize.ThecharacteristicvelocityfortheRenumberiscomputedfromthelocalmassflowandthecross-sectionalarea.Herethesurfaceoverwhichtheheatisexchanged,aswellasthewalltemperature,dependontherotationangleθofthemainrotor.

Theenergygainduetothegasinflowintotheworkingvolumeisrepresentedbytheproductofthemassintakeanditsaveragedenthalpy.Assuch,theenergyinflowvarieswiththerotationalangle.Duringthesuctionperiod,gasenterstheworkingvolumebringingtheaveragedgasenthalpy,

523CalculationofScrewCompressorPerformancewhichdominatesinthesuctionchamber.However,duringthetimewhenthesuctionportisclosed,acertainamountofthecompressedgasleaksintothecompressorworkingchamberthroughtheclearances.Themassofthisgas,aswellasitsenthalpyaredeterminedonthebasisofthegasleakageequations.Theworkingvolumeisfilledwithgasduetoleakageonlywhenthegaspressureinthespacearoundtheworkingvolumeishigher,otherwisethereisnoleakage,oritisintheoppositedirection,i.e.fromtheworkingchambertowardsotherplenums.

Thetotalinflowenthalpyisfurthercorrectedbytheamountofenthalpybroughtintotheworkingchamberbytheinjectedoil.

Theenergylossduetothegasoutflowfromtheworkingvolumeisdefinedbytheproductofthemassoutflowanditsaveragedgasenthalpy.Duringdelivery,thisisthecompressedgasenteringthedischargeplenum,while,inthecaseofexpansionduetoinappropriatedischargepressure,thisisthegaswhichleaksthroughtheclearancesfromtheworkingvolumeintotheneighbouringspaceatalowerpressure.Ifthepressureintheworkingchamberislowerthanthatinthedischargechamberandifthedischargeportisopen,theflowwillbeinthereversedirection,i.e.fromthedischargeplenumintotheworkingchamber.Thechangeofmasshasanegativesign

anditsassumedenthalpyisequaltotheaveragedgasenthalpyinthepressurechamber.

ThethermodynamicworksuppliedtothegasduringthecompressionprocessisrepresentedbythetermpdVdθ.Thistermisevaluatedfromthelocalpressureandlocalvolumechangerate.Thelatterisobtainedfromtherelationshipsdefiningthescrewkinematicswhichyieldtheinstantaneousworkingvolumeanditschangewithrotationangle.InfactthetermdV/dϕcanbeidentifiedwiththeinstantaneousinterlobearea,correctedforthecapturedandoverlappingareas.

Ifoilorotherfluidisinjectedintotheworkingchamberofthecompressor,theoilmassinflowanditsenthalpyshouldbeincludedintheinflowterms.Inspiteofthefactthattheoilmassfractioninthemixtureissignificant,itseffectuponthevolumeflowrateisonlymarginalbecausetheoilvolumefractionisusuallyverysmall.Thetotalfluidmassoutflowalsoincludestheinjectedoil,thegreaterpartofwhichremainsmixedwiththeworkingfluid.Heattransferbetweenthegasandoildropletsisdescribedbyafirstorderdifferentialequation.

TheMassContinuityEquation

(3.4)

Themassinflowrateconsistsof:

(3.5)

3.1OneDimensionalMathematicalModel53

Themassoutflowrateconsistsof:

(3.6)

Eachofthemassflowratesatisfiesthecontinuityequation

(3.7)

wherew[m/s]denotesfluidvelocity,ρ–fluiddensityandA–theflowcrosssection

area.Theinstantaneousdensityρ=ρ(θ)isobtainedfromtheinstantaneousmassmtrappedinthecontrolvolumeandthesizeofthecorrespondinginstantaneousvolumeV,asρ=m/V.

3.1.2SuctionandDischargePorts

Thecross-sectionareaAisobtainedfromthecompressorgeometryanditmaybeconsideredasaperiodicfunctionoftheangleofrotationθ.Thesuctionportareaisdefinedby:

(3.8)

wheresucmeansthestartingvalueofθatthemomentofthesuctionportopening,andAsuc,0denotesthemaximumvalueofthesuctionportcrosssectionarea.Thereferencevalueoftherotationangleθisassumedatthesuctionportclosingsothatsuctionendsatθ=0,ifnotspecifieddifferently.

Thedischargeportareaislikewisedefinedby:

(3.9)

wheresubscriptedenotestheendofdischarge,cdenotestheendofcompressionandAdis,0standsforthemaximumvalueofthedischargeportcrosssectionalarea.

SuctionandDischargePortFluidVelocities

(3.10)

whereμisthesuction/dischargeorificeflowcoefficient,whilesubscripts1and2denotetheconditionsdownstreamandupstreamoftheconsideredport.Theprovisionsuppliedinthecomputercodewillcalculateforareverseflowifh2543CalculationofScrewCompressorPerformance

3.1.3GasLeakages

Leakagesinascrewmachineamounttoasubstantialpartofthetotalflowrateandthereforeplayanimportantrolebecausetheyinfluencetheprocessbothbyaffectingthecompressormassflowrateorcompressordelivery,i.e.volumetricefficiencyandthethermodynamicefficiencyofthecompressionwork.Forpracticalcomputationoftheeffectsofleakageuponthecompressorprocess,itisconvenienttodistinguishtwotypesofleakages,accordingtotheirdirectionwithregardtotheworkingchamber:

gainandlossleakages.Thegainleakagescomefromthedischargeplenumandfromtheneighbouringworkingchamberwhichhasahigherpressure.Thelossleakagesleavethechambertowardsthesuctionplenumandtotheneighbouringchamberwithalowerpressure.

Computationoftheleakagevelocityfollowsfromconsiderationofthefluidflowthroughtheclearance.TheprocessisessentiallyadiabaticFanno-flow.Inordertosimplifythecomputation,theflowisissometimesassumedtobeatconstanttemperatureratherthanatconstantenthalpy.Thisdeparturefromtheprevailingadiabaticconditionshasonlyamarginalinfluenceiftheanalysisiscarriedoutindifferentialform,i.e.forthesmallchangesoftherotationalangle,asfollowedinthepresentmodel.Thepresentmodeltreatsonlygasleakage.Noattemptismadetoaccountforleakageofagas-liquidmixture,whiletheeffectoftheoilfilmcanbeincorporatedbyanappropriatereductionoftheclearancegaps.

Anidealizedclearancegapisassumedtohavearectangularshapeandthemassflowofleakingfluidisexpressedbythecontinuityequation:

(3.11)

whererandwaredensityandvelocityoftheleakinggas,Ag=lgδgtheclearancegapcross-sectionalarea,lgleakageclearancelength,sealingline,δgleakageclearancewidthorgap,μ=μ(Re,Ma)theleakageflowdischargecoefficient.

Fourdifferentsealinglinesaredistinguishedinascrewcompressor:

theleadingtipsealinglineformedbetweenthemainandgaterotorforwardtipandcasing,thetrailingtipsealinglineformedbetweenthemainandgatereversetipandcasing,thefrontsealinglinebetweenthedischargerotorfrontandthehousingandtheinterlobesealinglinebetweentherotors.

Allsealinglineshaveclearancegapswhichformleakageareas.Additionally,thetipleakageareasareaccompaniedbyblow-holeareas.

Accordingtothetypeandpositionofleakageclearances,fivedifferentleakagescanbeidentified,namely:

lossesthroughthetrailingtipsealingandfrontsealingandgainsthroughtheleadingandfrontsealing.Thefifth,“throughleakage”doesnotdirectlyaffecttheprocessintheworkingchamber,butitpassesthroughitfromthedischargeplenumtowardsthesuctionport.

Theleakinggasvelocityisderivedfromthemomentumequation,whichaccountsforthefluid-wallfriction:

3.1OneDimensionalMathematicalModel55

(3.12)

wheref(Re,Ma)isthefrictioncoefficientwhichisdependentontheReynoldsandMachnumbers,Dgistheeffectivediameteroftheclearancegap,Dg≈2δganddxisthelengthincrement.FromthecontinuityequationandassumingthatT≈consttoeliminategasdensityintermsofpressure,theequationcanbeintegratedintermsofpressurefromthehighpressuresideatposition2tothelowpressuresideatposition1ofthegapto