9101fform2QMS过程矩阵报告ul.docx

《9101fform2QMS过程矩阵报告ul.docx》由会员分享,可在线阅读,更多相关《9101fform2QMS过程矩阵报告ul.docx(28页珍藏版)》请在冰豆网上搜索。

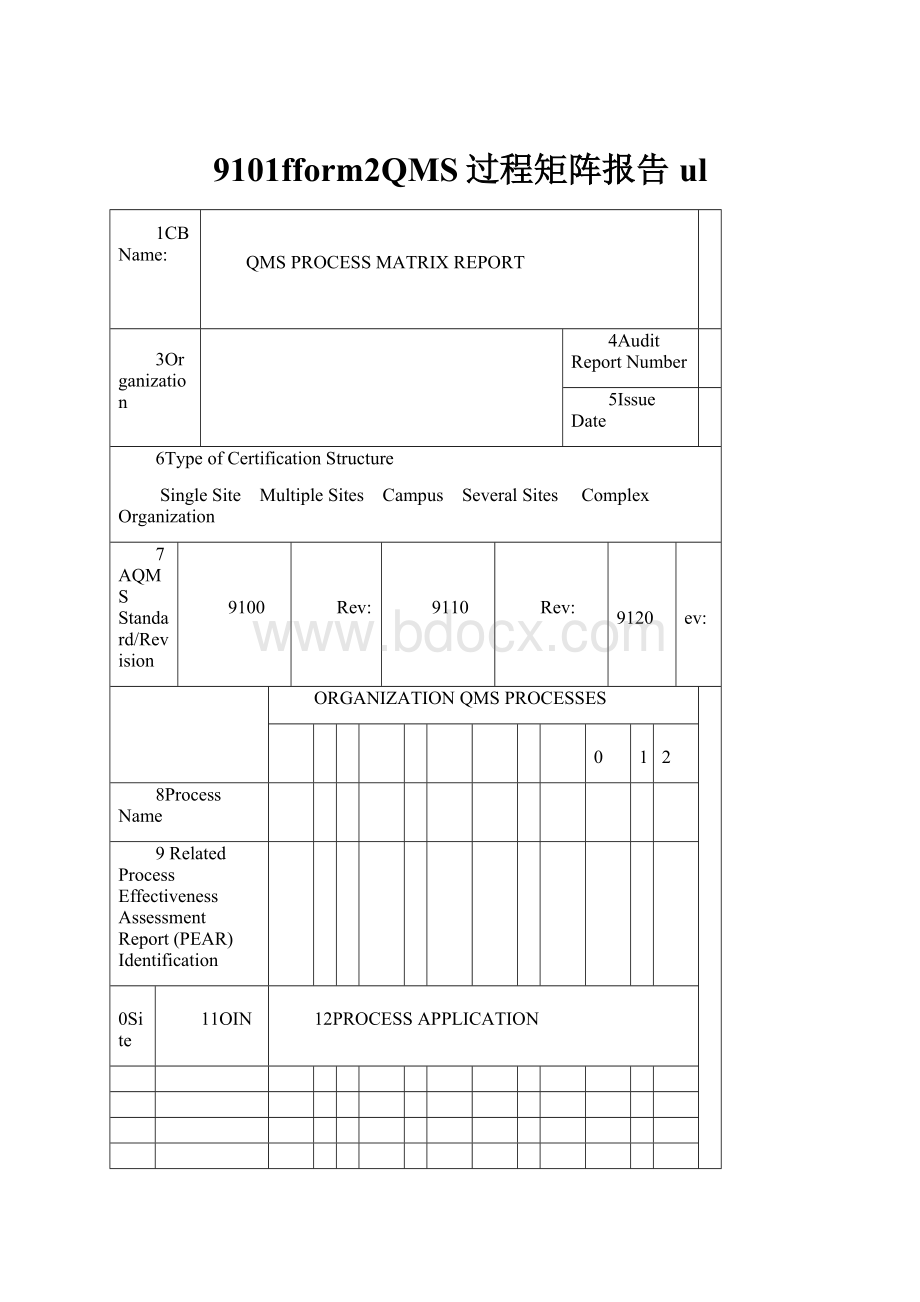

9101fform2QMS过程矩阵报告ul

1CBName:

QMSPROCESSMATRIXREPORT

2

3Organization

4AuditReportNumber

5IssueDate

6TypeofCertificationStructure

SingleSiteMultipleSitesCampusSeveralSitesComplexOrganization

7AQMSStandard/Revision

9100

Rev:

9110

Rev:

9120

Rev:

ORGANIZATIONQMSPROCESSES

1

2

3

4

5

6

7

8

9

10

11

12

8ProcessName

9RelatedProcessEffectivenessAssessmentReport(PEAR)Identification

10Site

11OIN

12PROCESSAPPLICATION

13ProcessEffectivenessLevel

1

2

3

4

5

9100SeriesClauses

(A)=Notapplicablefor9100

(B)=Notapplicablefor9110

(C)=Notapplicablefor9120

14Conformity

15NCRNumberandClassification

1

2

3

4

5

6

7

8

9

10

11

12

4.

ContextoftheOrganization

4.1

UnderstandingtheOrganizationanditsContext

4.2

UnderstandingtheNeedsandExpectationsofInterestedParties

4.3

DeterminingtheScopeoftheQualityManagementSystem

4.4

QualityManagementSystemanditsProcesses

4.4.1

4.4.2

16SummaryofObjectiveEvidence:

5.

Leadership

5.1

LeadershipandCommitment

5.1.1

General

5.1.2

CustomerFocus

9100SeriesClauses

(A)=Notapplicablefor9100

(B)=Notapplicablefor9110

(C)=Notapplicablefor9120

14Conformity

15NCRNumberandClassification

1

2

3

4

5

6

7

8

9

10

11

12

5.2

Policy

5.2.1

EstablishingtheQualityPolicy

5.2.2

CommunicatingtheQualityPolicy

5.2.3

EstablishingandCommunicatingtheSafetyPolicy(A)(C)

5.3

OrganizationalRoles,Responsibilities,andAuthorities

5.3.1

AccountableManager(A)(C)

5.3.2

QualityManager(A)(C)

5.3.3

OtherAppointedManager(s)(A)(C)

16SummaryofObjectiveEvidence:

6.

Planning

6.1

ActionstoAddressRisksandOpportunities

6.1.1

6.1.2

6.2

QualityObjectivesandPlanningtoAchieveThem

6.2.1

6.2.2

6.3

PlanningofChanges

9100SeriesClauses

(A)=Notapplicablefor9100

(B)=Notapplicablefor9110

(C)=Notapplicablefor9120

14Conformity

15NCRNumberandClassification

1

2

3

4

5

6

7

8

9

10

11

12

16SummaryofObjectiveEvidence:

7.

Support

7.1

Resources

7.1.1

General

7.1.2

People

7.1.3

Infrastructure

7.1.4

EnvironmentfortheOperationofProcesses

7.1.5

MonitoringandMeasuringResources

7.1.5.1

General

7.1.5.2

MeasurementTraceability

7.1.6

OrganizationalKnowledge

7.2

Competence

7.3

Awareness

7.4

Communication

7.5

DocumentedInformation

7.5.1

General

7.5.2

CreatingandUpdating

9100SeriesClauses

(A)=Notapplicablefor9100

(B)=Notapplicablefor9110

(C)=Notapplicablefor9120

14Conformity

15NCRNumberandClassification

1

2

3

4

5

6

7

8

9

10

11

12

7.5.3

Controlofdocumentedinformation

7.5.3.1

7.5.3.2

16SummaryofObjectiveEvidence:

8.

Operation

8.1

OperationalPlanningandControl

8.1.1

OperationalRiskManagement(C)

8.1.2

ConfigurationManagement

8.1.3

ProductSafety(C)

8.1.4

PreventionofCounterfeitParts

8.1.5

PreventionofSuspectedUnapprovedParts(A)

8.1.6

InstallationofApprovedParts(A)(C)

8.2

RequirementsforProductsandServices

8.2.1

CustomerCommunication

8.2.2

DeterminingtheRequirementsforProductsandServices

8.2.3

ReviewoftheRequirementsforProductsandServices

8.2.3.1

8.2.3.2

9100SeriesClauses

(A)=Notapplicablefor9100

(B)=Notapplicablefor9110

(C)=Notapplicablefor9120

14Conformity

15NCRNumberandClassification

1

2

3

4

5

6

7

8

9

10

11

12

8.2.4

ChangestoRequirementsforProductsandServices

8.3

DesignandDevelopmentofProductsandServices

8.3.1

General

8.3.2

DesignandDevelopmentPlanning

8.3.3

DesignandDevelopmentInputs

8.3.4

DesignandDevelopmentControls

8.3.4.1

DesignandDevelopmentControls(B)(C)

8.3.5

DesignandDevelopmentOutputs

8.3.6

DesignandDevelopmentChanges

8.4

ControlofExternallyProvidedProcesses,Products,andServices

8.4.1

General

8.4.1.1

8.4.2

TypeandExtentofControl

8.4.3

InformationforExternalProviders

8.5

ProductionandServiceProvision

8.5.1

ControlofProductionandServiceProvision

8.5.1.1

ControlofEquipment,Tools,andsoftwareprograms

8.5.1.2

ValidationandControlofSpecialProcesses(C)

9100SeriesClauses

(A)=Notapplicablefor9100

(B)=Notapplicablefor9110

(C)=Notapplicablefor9120

14Conformity

15NCRNumberandClassification

1

2

3

4

5

6

7

8

9

10

11

12

8.5.1.3

ProductionProcessVerification(B)(C)

8.5.1.4

EvaluationofaNewCapability(A)(C)

8.5.2

IdentificationandTraceability

8.5.3

PropertyBelongingtoCustomersorExternalProviders

8.5.4

Preservation

8.5.5

Post-deliveryActivities

8.5.6

ControlofChanges

8.6

ReleaseofProductsandServices

8.7

ControlofNonconformingOutputs

8.7.1

8.7.2

9.

PerformanceEvaluation

9.1

Monitoring,Measurement,Analysis,andEvaluation

9.1.1

General

9.1.2

CustomerSatisfaction

9.1.3

AnalysisandEvaluation

9100SeriesClauses

(A)=Notapplicablefor9100

(B)=Notapplicablefor9110

(C)=Notapplicablefor9120

14Conformity

15NCRNumberandClassification

1

2

3

4

5

6

7

8

9

10

11

12

9.2

InternalAudit

9.2.1

9.2.2

9.3

ManagementReview

9.3.1

General

9.3.2

ManagementReviewInputs

9.3.3

ManagementReviewOutputs

16SummaryofObjectiveEvidence:

10.

Improvement

10.1

General

10.2

NonconformityandCorrectiveAction

10.2.1

10.2.2

10.3

ContinualImprovement

16SummaryofObjectiveEvidence:

17AuditorName(s)

DISCLAIMERSTATEMENT

Thisauditwasconductedbasedonasamplingprocessoftheavailableinformation.

Form2:

QMSProcessMatrixReportInstructions

Item#

Description

1

EnterthenameoftheCertificationBody(CB)conductingtheaudit.

2

UsetheIAQGlogoasdefaultorentertheCBlogo(optional).

3

Enterthenameoftheorganization.

4

Entertheauditreportnumber.

5

Enterthedatethatthematrixwascreated.

6

Entertheapplicablecertificationstructure.

7

EntertheapplicableAerospaceQualityManagementSystem(AQMS)standard(s)includingtherevisionlevel.

8

Entertheorganizationprocessnamestobeaudited.

NOTE:

Iftherearemoreprocessesthancolumns,additionalformscanbeused.

9

EntertheProcessEffectivenessAssessmentReport(PEAR)identificationascompletedfortheprocessesindicatedinbox“8”.Enter“N/A”forthoseprocessesnotrelatedtoclause8ofthe9100-seriesstandardandnoPEARhasbeeninitiated.

10

Enterthenameoftheorganizationsite(s)