ISO 9001 中英文.docx

《ISO 9001 中英文.docx》由会员分享,可在线阅读,更多相关《ISO 9001 中英文.docx(64页珍藏版)》请在冰豆网上搜索。

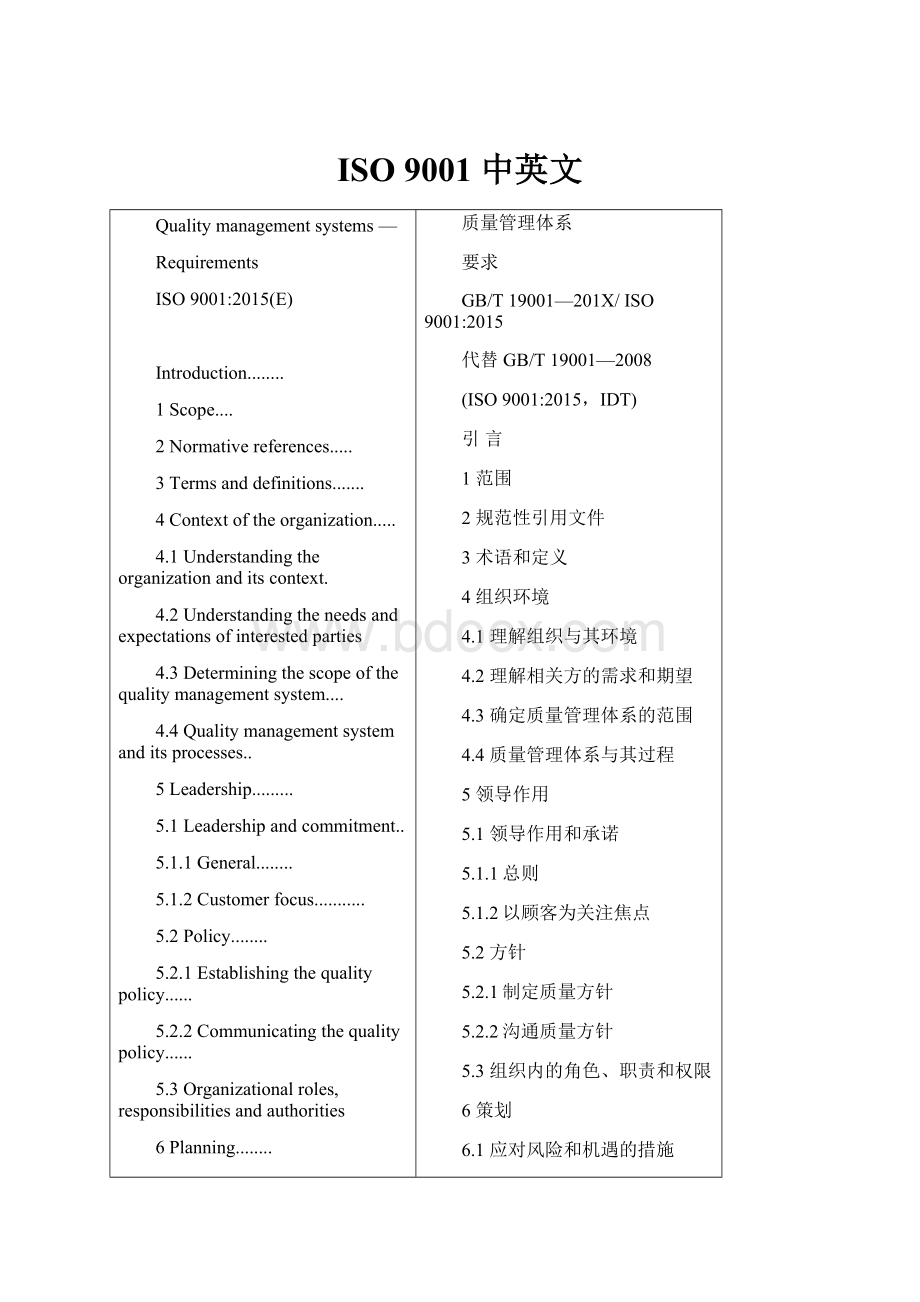

ISO9001中英文

Qualitymanagementsystems—

Requirements

ISO9001:

2015(E)

Introduction........

1Scope....

2Normativereferences.....

3Termsanddefinitions.......

4Contextoftheorganization.....

4.1Understandingtheorganizationanditscontext.

4.2Understandingtheneedsandexpectationsofinterestedparties

4.3Determiningthescopeofthequalitymanagementsystem....

4.4Qualitymanagementsystemanditsprocesses..

5Leadership.........

5.1Leadershipandcommitment..

5.1.1General........

5.1.2Customerfocus...........

5.2Policy........

5.2.1Establishingthequalitypolicy......

5.2.2Communicatingthequalitypolicy......

5.3Organizationalroles,responsibilitiesandauthorities

6Planning........

6.1Actionstoaddressrisksandopportunities........

6.2Qualityobjectivesandplanningtoachievethem..

6.3Planningofchanges...........

7Support............

7.1Resources....

7.1.1General....

7.1.2People...

7.1.3Infrastructure.......

7.1.4Environmentfortheoperationofprocesses.

7.1.5Monitoringandmeasuringresources..

7.1.6Organizationalknowledge......

7.2Competence....

7.3Awareness...

7.4Communication.....

7.5Documentedinformation.............

7.5.1General......

7.5.2Creatingandupdating...........

7.5.3Controlofdocumentedinformation

8Operation.....

8.1Operationalplanningandcontrol...........

8.2Requirementsforproductsandservices....

8.2.1Customercommunication.....

8.2.2Determiningtherequirementsforproductsandservices....

8.2.3Reviewoftherequirementsforproductsandservices..

8.2.4Changestorequirementsforproductsandservices......

8.3Designanddevelopmentofproductsandservices....

8.3.1General......

8.3.2Designanddevelopmentplanning...

8.3.3Designanddevelopmentinputs....

8.3.4Designanddevelopmentcontrols.......

8.3.5Designanddevelopmentoutputs........

8.3.6Designanddevelopmentchanges....

8.4Controlofexternallyprovidedprocesses,productsandservices..

8.4.1General......

8.4.2Typeandextentofcontrol.......

8.4.3Informationforexternalproviders.............

8.5Productionandserviceprovision.....

8.5.1Controlofproductionandserviceprovision...

8.5.2Identificationandtraceability.......

8.5.3Propertybelongingtocustomersorexternalproviders

8.5.4Preservation......

8.5.5Post-deliveryactivities........

8.5.6Controlofchanges..................

8.6Releaseofproductsandservices...

8.7Controlofnonconformingoutputs......

9Performanceevaluation....

9.1Monitoring,measurement,analysisandevaluation....

9.1.1General..

9.1.2Customersatisfaction..

9.1.3Analysisandevaluation.....

9.2Internalaudit.......

9.3Managementreview..

9.3.1General......

9.3.2Managementreviewinputs.

9.3.3Managementreviewoutputs......

10Improvement.......

10.1General........

10.2Nonconformityandcorrectiveaction.....

10.3Continualimprovement.....

AnnexA(informative)Clarificationofnewstructure,terminologyandconcepts..

AnnexB(informative)OtherInternationalStandardsonqualitymanagementandqualitymanagementsystemsdevelopedbyISO/TC176..

Bibliography.....

Introduction

0.1General

Theadoptionofaqualitymanagementsystemisastrategicdecisionforanorganizationthatcanhelptoimproveitsoverallperformanceandprovideasoundbasisforsustainabledevelopmentinitiatives.

ThepotentialbenefitstoanorganizationofimplementingaqualitymanagementsystembasedonthisInternationalStandardare:

a)theabilitytoconsistentlyprovideproductsandservicesthatmeetcustomerandapplicablestatutoryandregulatoryrequirements;

b)facilitatingopportunitiestoenhancecustomersatisfaction;

c)addressingrisksandopportunitiesassociatedwithitscontextandobjectives;

d)theabilitytodemonstrateconformitytospecifiedqualitymanagementsystemrequirements.

ThisInternationalStandardcanbeusedbyinternalandexternalparties.

ItisnottheintentofthisInternationalStandardtoimplytheneedfor:

—uniformityinthestructureofdifferentqualitymanagementsystems;

—alignmentofdocumentationtotheclausestructureofthisInternationalStandard;

—theuseofthespecificterminologyofthisInternationalStandardwithintheorganization.

ThequalitymanagementsystemrequirementsspecifiedinthisInternationalStandardarecomplementarytorequirementsforproductsandservices.

ThisInternationalStandardemploystheprocessapproach,whichincorporatesthePlan-Do-Check-Act(PDCA)cycleandrisk-basedthinking.

Theprocessapproachenablesanorganizationtoplanitsprocessesandtheirinteractions.

ThePDCAcycleenablesanorganizationtoensurethatitsprocessesareadequatelyresourcedandmanaged,andthatopportunitiesforimprovementaredeterminedandactedon.

Risk-basedthinkingenablesanorganizationtodeterminethefactorsthatcouldcauseitsprocessesanditsqualitymanagementsystemtodeviatefromtheplannedresults,toputinplacepreventivecontrolstominimizenegativeeffectsandtomakemaximumuseofopportunitiesastheyarise(seeClauseA.4).

Consistentlymeetingrequirementsandaddressingfutureneedsandexpectationsposesachallengefororganizationsinanincreasinglydynamicandcomplexenvironment.Toachievethisobjective,theorganizationmightfinditnecessarytoadoptvariousformsofimprovementinadditiontocorrectionandcontinualimprovement,suchasbreakthroughchange,innovationandre-organization.

InthisInternationalStandard,thefollowingverbalformsareused:

—“shall”indicatesarequirement;

—“should”indicatesarecommendation;

—“may”indicatesapermission;

—“can”indicatesapossibilityoracapability.

Informationmarkedas“NOTE”isforguidanceinunderstandingorclarifyingtheassociatedrequirement.

0.2Qualitymanagementprinciples

ThisInternationalStandardisbasedonthequalitymanagementprinciplesdescribedinISO9000.Thedescriptionsincludeastatementofeachprinciple,arationaleofwhytheprincipleisimportantfortheorganization,someexamplesofbenefitsassociatedwiththeprincipleandexamplesoftypicalactionstoimprovetheorganization’sperformancewhenapplyingtheprinciple.

Thequalitymanagementprinciplesare:

—customerfocus;

—leadership;

—engagementofpeople;

—processapproach;

—improvement;

—evidence-baseddecisionmaking;

—relationshipmanagement.

0.3Processapproach

0.3.1General

ThisInternationalStandardpromotestheadoptionofaprocessapproachwhendeveloping,implementingandimprovingtheeffectivenessofaqualitymanagementsystem,toenhancecustomersatisfactionbymeetingcustomerrequirements.Specificrequirementsconsideredessentialtotheadoptionofaprocessapproachareincludedin4.4.

Understandingandmanaginginterrelatedprocessesasasystemcontributestotheorganization’seffectivenessandefficiencyinachievingitsintendedresults.Thisapproachenablestheorganizationtocontroltheinterrelationshipsandinterdependenciesamongtheprocessesofthesystem,sothattheoverallperformanceoftheorganizationcanbeenhanced.

Theprocessapproachinvolvesthesystematicdefinitionandmanagementofprocesses,andtheirinteractions,soastoachievetheintendedresultsinaccordancewiththequalitypolicyandstrategicdirectionoftheorganization.ManagementoftheprocessesandthesystemasawholecanbeachievedusingthePDCAcycle(see0.3.2)withanoverallfocusonrisk-basedthinking(see0.3.3)aimedattakingadvantageofopportunitiesandpreventingundesirableresults.

Theapplicationoftheprocessapproachinaqualitymanagementsystemenables:

a)understandingandconsistencyinmeetingrequirements;

b)theconsiderationofprocessesintermsofaddedvalue;

c)theachievementofeffectiveprocessperformance;

d)improvementofprocessesbasedonevaluationofdataandinformation.

Figure1givesaschematicrepresentationofanyprocessandshowstheinteractionofitselements.Themonitoringandmeasuringcheckpoints,whicharenecessaryforcontrol,arespecifictoeachprocessandwillvarydependingontherelatedrisks.

Figure1—Schematicrepresentationoftheelementsofasingleprocess

0.3.2Plan-Do-Check-Actcycle

ThePDCAcyclecanbeappliedtoallprocessesandtothequalitymanagementsystemasawhole.Figure2illustrateshowClauses4to10canbegroupedinrelationtothePDCAcycle.

NOTENumbersinbracketsrefertotheclausesinthisInternationalStandard.

Figure2—RepresentationofthestructureofthisInternationalStandardinthePDCAcycle

ThePDCAcyclecanbebrieflydescribedasfollows:

—Plan:

establishtheobjectivesofthesystemanditsprocesses,andtheresourcesneededtodeliverresultsinaccordancewithcustomers’requirementsandtheorganization’spolicies,andidentifyandaddressrisksandopportunities;

—Do:

implementwhatwasplanned;

—Check:

monitorand(whereapplicable)measureprocessesandtheresultingproductsandservicesagainstpolicies,objectives,requirementsandplannedactivities,andreporttheresults;

—Act:

takeactionstoimproveperformance,asnecessary.

0.3.3Risk-basedthinking

Risk-basedthinking(seeClauseA.4)isessentialforachievinganeffectivequalitymanagementsystem.Theconceptofrisk-basedthinkinghasbeenimplicitinpreviouseditionsofthisInternationalStandardincluding,forexample,carryingoutpreventiveactiontoeliminatepotentialnonconformities,analyzinganynonconformitiesthatdooccur,andtakingactiontopreventrecurrencethatisappropriatefortheeffectsofthenonconformity.

ToconformtotherequirementsofthisInternationalStandard,anorganizationneedstoplanandimplementactionstoad