华工成型技术重点第一部分总结Word格式.docx

《华工成型技术重点第一部分总结Word格式.docx》由会员分享,可在线阅读,更多相关《华工成型技术重点第一部分总结Word格式.docx(28页珍藏版)》请在冰豆网上搜索。

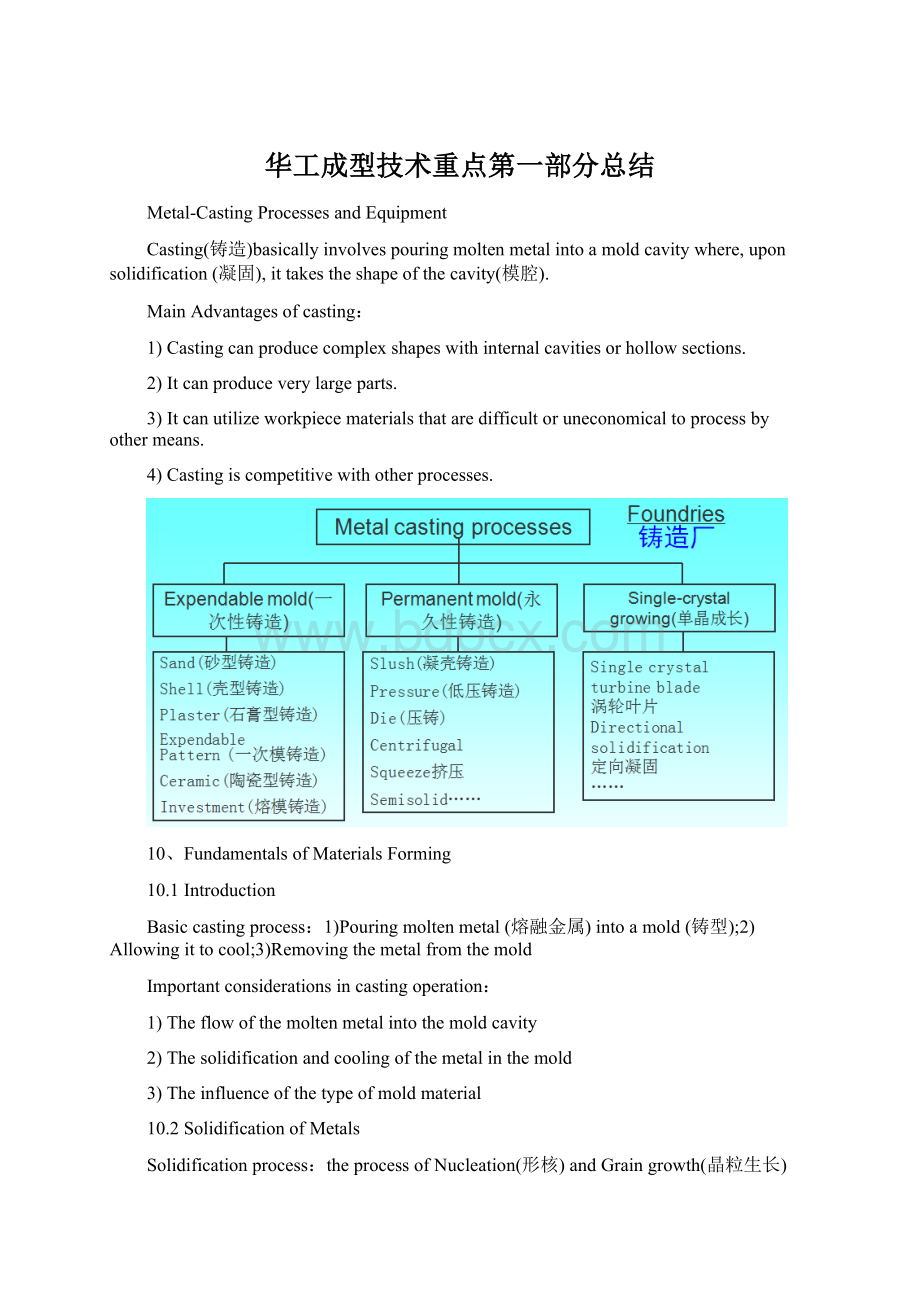

2)Thesolidificationandcoolingofthemetalinthemold

3)Theinfluenceofthetypeofmoldmaterial

10.2SolidificationofMetals

Solidificationprocess:

theprocessofNucleation(形核)andGraingrowth(晶粒生长)

Nucleation(形核):

Ultra-fine(超细的)crystallites(nuclei)formfromtheliquid.Themethodsofnucleation:

homogeneousnucleation(均匀形核)andheterogeneousnucleation(非均匀形核)

Graingrowth(晶粒生长):

Nucleibegintogrowasatomsareattachedtothenucleiuntilnoliquidremains.Themethodsofgraingrowth:

PlanarGrowth(平面状生长)andDendriticGrowth(枝晶生长)

10.2.1PureMetals

PureMetalhasaclearlydefinedmeltingpoint(熔点),soitsolidifiesataconstanttemperature

Chillzone激冷晶区(表面细晶);

Equiaxedgrai等轴晶;

Columnargrain柱状晶

Fig.10.1Schematicillustrationofthreecaststructuresofmetalssolidifiedinasquaremold:

(a)puremetals;

(b)solid-solutionalloys;

and(c)structureobtainedbyusingnucleatingagents

图10.1是金属三种铸造结构在方形模具中的示意图:

(a)纯金属;

(b)固溶体合金;

(c)通过使用成核剂得到的结构

Fig.10.2Developmentofapreferredtextureatacoolmoldwall图10.2是在冷却模腔中晶粒首先发展的纹理

10.2.2Alloys

Solidificationinalloysbeginswhenthetemperaturedropsbelowtheliquidus,TLandiscompletedwhenitreachesthesolidus,TS.Withinthistemperaturerange,thealloyisinamushyorpastystatewithcolumnardendrites.

Liquidus固相线TL;

Solidus液相线TS;

Columnardendrites柱状枝晶;

Mushyzone糊状区(S+L);

Freezingrange=TL–TS凝固温度范围

Thewidthofthemushyzone,wherebothliquidandsolidphasesarepresent,isanimportantfactorduringsolidification.Thezoneisdescribedintermsofatemperaturedifference,knownasthefreezingrange.

Fig.10.3Schematicillustrationofalloysolidificationandtemperaturedistributioninthesolidifyingmetal

图10.3是合金凝固和凝固金属的温度分布示意图

Effectsofcoolingrate(冷却速率):

1)Solidificationtimeaffectsthesizeofdendrites.

2)Normally,longsolidificationtimeorslowcoolingrate(ontheorderof102K/s,regularcasting)resultsincoarsedendriticstructures(粗大枝状晶);

forshortsolidificationtimeorfastercoolingrate(ontheorderof104K/s,forcedchill激冷),thestructurebecomefiner(更细小).

3)Underhighcoolingrate(about106–108K/s,atomization雾化),amorphousstructure(非晶结构)maybeobtained.

4)Asgrainsizedecreases,thestrengthandtheductilityofthecastalloyincrease,micro-porosityinthecastingdecreases,andthetendencyforthecastingtocrack(hottearing)duringsolidificationdecreases

Highcoolingrate⇒finermicrostructureandsmallerdendritearmspacing枝晶间距⇒higherstrength强度andductility延伸性,lowermicro-porosity微观孔洞,lesserhottearing热裂.

G/R:

acriterion判据describingthekinetics动力学oftheliquid-solidinterfaceduringsolidification.

G/R=thethermalgradient温度梯度/themovingrateofliquid-solidinterface界面

Fig.10.5Threebasictypesofcaststructures:

(a)columnardendritic;

(b)equiaxed等轴dendritic;

(c)equiaxednondendritic.图10.5是三种基本类型的铸态结构组成:

(a)(柱状树枝状;

(b)等轴等轴树突状;

(c)等轴非枝晶

10.2.3Structure-PropertyRelationship

Segregation(偏析):

铸件中化学成分不均匀的现象

Whenthealloyiscooledveryslowly,eachdendritedevelopsauniformcomposition.Underthenormal(faster)coolingratesencounteredinpractice,however,coreddendritesareformed.Coreddendriteshavesurfacecompositiondifferentfromthatattheircenters(thedifferenceisreferredtoasaconcentrationgradient).

当合金冷却速度非常缓慢时,每个枝状晶发展成均匀的组成物。

实际中在正常(更快)的冷却速度会形成芯部枝晶。

芯部枝晶的表面与其中心相比有不同的组成物(这种差异叫做浓度梯度)

Microsegregation(微观偏析,微小范围内的成分不均匀):

Thesurfacehasahigherconcentrationofalloyingelementsthandoesthecoreofthedendrites,owingtosoluterejectionfromthecoretowardthesurfaceduringsolidificationofthedendrites(microsegregation).ThedarkershadingintheinterdendriticliquidnearthedendriterootinFig.10.5indicatesthattheseregionshaveahighersoluteconcentration;

microsegregationintheseregionsismuchmorepronouncedthaninothers.

表面合金元素的浓度高于枝状晶粒的芯部,因为在枝状晶凝固的过程中芯部朝向表面的方向存在溶质排斥的效果。

图.10.5中在靠近枝状晶间根部的枝晶间的液体中的深色阴影显示,这些区域有较高的溶质浓度;

显微偏析在这些区域比其他区域更加明显。

Macrosegregation(宏观偏析,铸件各部位的成分不均匀):

Macrosegregationinvolvesdifferencesincompositionthroughoutthecastingitself.

宏观偏析涉及整个铸造本身在组合物中的差异。

1)Normalsegregation(正常偏析):

Insituationwherethesolidifyingfrontmovesawayfromthesurfaceofacastingasaplanefront,lower-meltingconstituentsinthesolidifyingalloyaredriventowardthecenter.Consequently,theconcentrationofalloyingelementsinthecenterishigherthanthatofthesurface.

Normalsegregation(正常偏析):

在远离铸件平面表面的凝固前端那个地方,在凝固合金中的低熔点成分被驱向中央。

因此,在中心的合金元素浓度比表面的要高。

Ccenter>

Csurface

2)Inversesegregation(逆偏析):

Indendriticstructuressuchasthosefoundinsolid-solutionalloys,thecenterofthecastinghasalowerconcentrationofalloyingelements.Thereasonisthatliquidmetal(havingahigherconcentrationofalloyselements)entersthecavitiesdevelopedfromsolidificationshrinkageinthedendritearms,whichhavesolidifiedsooner.Ccenter<

Csurface

Insituationof

(1)Longfreezingrangealloys;

(2)Coarsedendriticstructure;

(3)Highgascontent

例如在固溶合金找到的在树枝状的结构,铸件的中心合金元素的浓度较低。

其原因是,合金元素浓度较高的液体金属进入从凝固收缩的枝状晶枝发展而来的空腔时凝固速度更快。

在

(1)凝固温度范围大的合金

(2)粗大枝晶结构(3)高气体成分的情况下容易发生逆偏析

3)Gravitysegregation(比重偏析):

Duringsolidification,Higher-densityinclusionssinkandLighterelementsfloat.Thecompositionofbottomortopofthecastingisdifferentfromotherparts

在凝固过程中,高密度的夹杂物下沉和较轻的元素上浮。

铸件的底部或顶部的组合物是与其它部分不同的

Discuss:

Whatwillhappenifanalloyismeltandsolidifiedinspace

Answer:

Lackofgravity-microgravity(微重力)andNoconvection(对流)

10.3FluidFlow(流体流动)

1)Terms:

pouringbasin,gatingsystem,sprue,runners,gate,risers.

Fig.10.7Schematicillustrationofatypicalriser-gatedcasting

PouringCup浇口杯

Sprue直浇道

Runner横浇道

Gate内浇口

Riser冒口

Themoltenmetalispouredthroughapouringbasinorcup.Itthenflowsthroughthegatingsystem(浇注系统sprue,runnersandgates)intothemoldcavity.

Sprue(直浇道)isaverticalchannelthroughwhichthemoltenmetalflowsdownwardinthemold.

Runners(横浇道)arethechannelsthatcarrythemoltenmetalfromthespruetothemoldcavity,orconnectthespruetothegate.

Gate(内浇口)isthatportionoftherunnerthroughwhichthemoltenmetalentersthemoldcavity.

Risers(冒口)serveasreservoirstosupplythemoltenmetalnecessarytopreventshrinkageduringsolidification.

熔融金属通过一个浇铸盆或杯子倾倒。

然后,它流经浇注系统(直浇道,横浇道以及内浇口)进入模腔。

直浇道是熔融金属在模具中向下流动的垂直通道。

横浇道是将熔融金属从直浇道输送到模腔的通道,或连接直浇道和内浇口的通道。

内浇口是熔融金属进入模腔中的横浇道中的一部分。

冒口是提供所必要熔融金属的储层,以防止在凝固过程中的收缩

ConsiderationsofGatingsystem(浇注系统):

Ensureadequatefluidflowinthesystem

Avoidproblemssuchasprematurecooling,turbulence(紊流),andgasentrapment

Trapcontaminants(oxideandotherinclusions)

Fillthemoldcavitysmoothly

2)Bernoulli’sTheorem

3)Continuity

4)FlowCharacteristics

Reynoldsnumber(Re雷诺数)isusedtoquantifythestateoffluid.ThehighertheRenumber,thegreaterthetendencyforturbulentflow(紊流).

10.4FluidityofMoltenMetal(熔融金属的流动性)

Fluidity(流动性):

Thecapabilityofthemoltenmetalstofillmoldcavity.Itconsistsoftwobasicfactors:

(1)characteristicsofthemoltenmetal;

and

(2)castingparameters.

Factorsinfluencingthefluidityofmoltenmetal:

TestsforFluidity:

10.5HeatTransfer

10.5.1SolidificationTime

Solidificationtimeisafunctionofthevolumeofacastinganditssurfacearea.

Solidificationtime=C(volume/surfacearea)2

whereCisaconstantthatreflectsmoldmaterial,metalproperties(includinglatentheat潜热),andtemperature.

10.5.2Shrinkage(收缩)

Becauseoftheirthermalexpansion(热膨胀)characteristics,metalsshrinkduringsolidificationandcooling.Shrinkage,whichcausedimensionalchangesand,sometimescracking,istheresultofthefollowingthreeevents:

1)Contraction(收缩)ofthemoltenmetalasitcoolspriortoitssolidification.

2)Contractionofthemetalduringphasechangefromliquidtosolid(latentheat潜热offusion熔化).

3)Contractionofthesolidifiedmetal(thecasting)asitstemperaturedropstoambient周围环境temperature.

因为它们的热膨胀特性,金属凝固和冷却过程中会收缩。

收缩,导致尺寸变化,有时导致开裂,是以下三个事件的结果:

1)在凝固之前冷却时熔融金属的收缩

2)从液相变为固相(熔化潜热释放)时金属的收缩

3)铸件的温度的下降至环境周围环境温度时铸件的收缩

10.6Defects(缺陷)

1)Metallicprojections(突出物):

fins,flash(飞边),ormassiveprojectionssuchasswellsandroughsurfaces.

2)Cavities:

roundedorroughinternalorexposedcavities,includingblow-holes,pinholes,andshrinkagecavities.

3)Discontinuities,suchascracks(裂纹),cold(冷裂)orhottearing(热裂),andcoldshuts(冷隔).

4)Defectivesurface,suchassurfacefolds,laps(重叠),scars,adhering(黏附)sandlayers,andoxide(氧化物)scale(剥落).

5)Incompletecasting,suchasmisruns(未铸满)(duetopremature(过早)solidification),insufficientvolumeofthemetalpoured,andrunout(型漏)(duetolossofmetalfrommoldafterpouring).Incompletecastingscanresultfromthemoltenmetalbeingattoolowatemperatureorfrompouringthemetaltooslowly.

6)Incorrectdimensionsorshape,owingtofactorssuchasimpropershrinkageallowance,patternmountingerror,irregularcontraction,d