对硝基甲苯合成对氨基苯甲酸实验报告Word下载.docx

《对硝基甲苯合成对氨基苯甲酸实验报告Word下载.docx》由会员分享,可在线阅读,更多相关《对硝基甲苯合成对氨基苯甲酸实验报告Word下载.docx(13页珍藏版)》请在冰豆网上搜索。

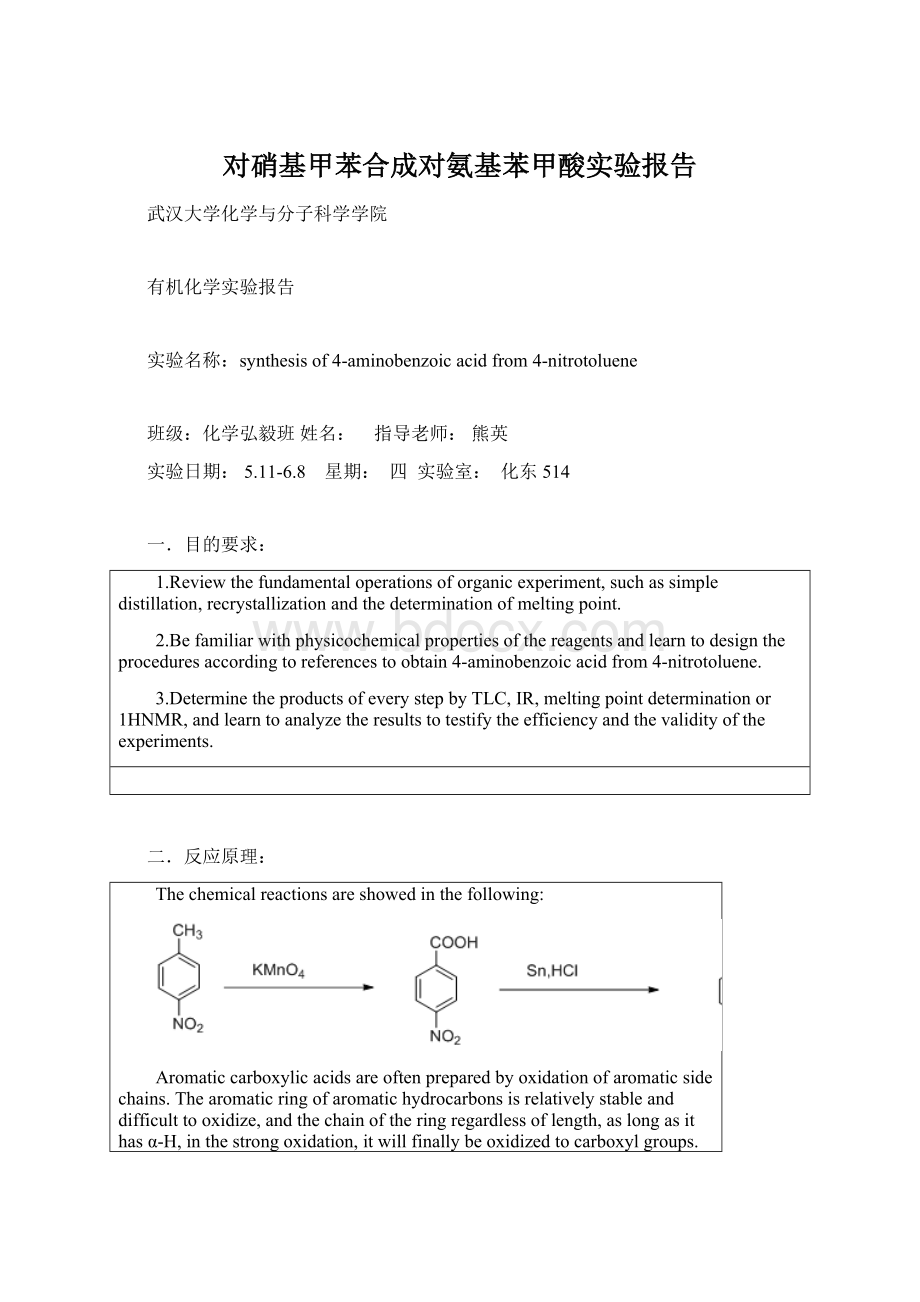

Aromaticcarboxylicacidsareoftenpreparedbyoxidationofaromaticsidechains.Thearomaticringofaromatichydrocarbonsisrelativelystableanddifficulttooxidize,andthechainoftheringregardlessoflength,aslongasithasα-H,inthestrongoxidation,itwillfinallybeoxidizedtocarboxylgroups.Thelaboratorygenerallyoxidizestoluenebypotassiumpermanganatetoproducebenzoicacid

Sincetolueneisinsolubleinpotassiumpermanganateaqueoussolution,thereactionisatwo-phasereaction,sothereactionneedstobesufficientlystirredandrefluxedatahighertemperatureforarelativelylongperiodoftime.Afterheatingandrefluxing,thepotassiumsaltofthebenzoicacidandtheprecipitationofmanganesedioxideareobtainedinthefirstplace.Theprecipitateisseparatedandthepotassiumsaltofthebenzoicacidisacidifiedwithhydrochloricacidtoobtainbenzoicacid,whichishardlysolubleinwaterandcrystallizedeasily.

ThereductionofnitrogroupcanbedonebyFepowderwithacetateorSnpowderwithcondensedHCl.Feismuchcheaperbuttheyieldislower,sowechoosetouseSnasreductant.Asamatteroffact,theSnsaltofaminobenzoicacidistoxicandneedsspecialcaretopreventskinexposureandinhalation.

三.主要试剂及产物的物理常数:

名称

分子量

性状

折光率

比重

熔点(oC)

沸点(oC)

溶解度(克/100ml溶剂)

水

醇

醚

4-nitrotoluene

137.1378

Yellowobliquefacadecrystal

1.5382

1.29

51.7

238.5

insoluble

Readilysoluble

4-nitrobenzoicacid

167.13

Yelloworwhiteobliquefacadecrystal

unknown

1.610

239~241

<

0.1g

soluble

4-aminobenzoicacid

137.14

Colorlessneedle-likecrystal

1.374(25℃)

187~187.5

Readilysoluble(hot)

sparinglysoluble(cold)

四.主要试剂用量及规格:

试剂名称

用量

规格

2.5g

A.R.

ligroin

20ml

60-90oC

Potassiumpermanganate

12.5g

NaOH(aq)

50%

Sulfuricacid

7.5ml

condensed

Ethylacetate

Sn

4g

powder

ammoniawater

30ml

Hydrochloricacid

15ml

cyclohexane

ethanol

五.实验装置图:

六.时间表

Time

synthesis

characterization

WEEK1

Oxidationof4-nitrotoluene

WEEK2

Purification

m.p.determination,TLC

IR

WEEK3

Reductionof4-nitrobenzoicacid

WEEK4

H-NMR

WEEK5

七.实验步骤及现象:

Thefirstweek:

oxidationofp-nitrotoluene

1.Preparationofcrudeproduct

Placethemagnetina100mlroundbottomflask,andadd2.5g(0.02mol)ofp-nitrotolueneand30mLofwater,chargetherefluxcondenser,stirandheattoreflux.Add6.00g(0.04mol)ofpotassiumpermanganateinportionsfromthemouthofthecondensertubewithin30minutes.Incaseofpotassiumpermanganatepluggingthecondenser,asmallamountofwatercanbeusedtorinsetheinnerwallofthecondensertube.Afterthat,plusasmallamountofwatertowashthepotassiumpermanganateattachedtotheinnerwallofthecondenserintothebottle,thetotalwatershouldnotexceed10mL.Continuerefluxuntilthetoluenelargelydisappears.Keeprefluxformorethan60minaftertheadditionofpotassiumpermanganate.

2.Crudeproductseparation

PumpthemixtureintheroundbottomflaskunderreducedpressurewithawaterpumpandwashtheMnO2residuewithasmallamountofhotwater.Ifthefiltrateispurple,addasmallamountofsaturatedsodiumbisulfitesolutiontomakethecolordisappear,andre-filter.Pourthefiltrateintoabeakerandplaceinanice-waterbath,coolandacidifywithconcentratedhydrochloricaciduntilallp-nitrobenzoicacidisprecipitated.Filtertheprecipitatedp-nitrobenzoicacidunderreducedpressure,washitwithasmallamountoficewater,andthendryittoobtaincrudeproduct.

Thesecondweek:

purificationandcharacterizationofp-nitrobenzoicacid

3.Productrefinement

Afterdrying,recrystallizedthecrudeproductinwater.Aftertheproductisdried,weighitandcalculatetheyield.

4.characterization

DoTLCanalysesofbothcrudeandpurifiedproduct,meltingpointdeterminationofbothcrudeandpurifiedproduct,IRdeterminationofpurifiedproduct.

Thethirdweek:

reductionofp-nitrobenzoicacid

5.Preparationofcrudeproduct

Placethemagnetina50mlthree-neckedflask,thenadd4g(0.025mol)ofSnpowder,2.00g(0.012mol)ofp-nitrobenzoicacidproductand5mlofwatertothemouth.Thenadd3.5ml(about0.04mol)ofconcentratedhydrochloricaciddropwisetothereactionsystem.Duringtheadditionofconcentratedhydrochloricacid,keepthemagnetspinning.Whentheadditioniscompleted,keepheatingtorefluxuntilthereactioniscompleted.

6.Crudeproductseparation

Coolingthesystem,thenadd50%sodiumhydroxidesolutiontothesystemisalkaline.Slowlyadddilutehydrochloricacid,precipitationofsolidwillappearintheicebath.Filterthecrudeproductunderreducedpressure.

Thefourthweek:

Recrystallizationofp-aminobenzoicacid

7.Productrefinement

Dissolvethecrudeproductwithasmallamountofethanolwithheating,andthenaddpetroleumether.Coolthesolutionandsolidprecipitates.

DoH-NMRdetermination.

Thefifthweek:

IRdeterminationandcleaningtheapparatus

8.characerizationandendoftheexperiment

DoIRdeterminationofthefinalproductandcleanandchecktheapparatuses.

Thepotassiumpermanganatewascrushedbyaglassstopper,andthenaddedintotheflaskin3timesin30minutes.(1:

40-14:

05)

Thepluginthecondenserblockoccurredinthesecondaddition.

Thesolutionturnedpurpleaftertheaddition,andsomebrownsubstanceclungtotheinnersurfaceoftheflask.Aftershaking,itgraduallydissolvedintothesolution.

Smallamountofsodiumbisulfitesolutionwasadded,andthesolutionfainted.

Relux(14:

05-15:

06)

0.85glightyellowsubsidencewascollected.

Thesubsidencewasaddedintoaround20mlwater,thenNaOHsolutionwasaddedtomakethesoliddissolve.Thesolutionbecamelightyellow.Byadditionofdilutehydrochloricacid,subsidenceappearedinicebath.

0.73gofrefinedgrayishyellowproductwasobtained.

Becausetheproductdidnotreachexpectedamount,otherchemicalswasmodifiedaccordingly.

Thedosage:

p-nitrobenzoicacid:

0.70g

Snpowder:

2.18g

H2O:

4ml

concentratedhydrochloricacid:

2.5ml

Thesolutionwasyellow.

TherestillremainedsomeSnpowderwhichwasseparatedbyfiltering.

Duringtheadditionofsodiumhydroxide,aseriesofphenomenonappeared:

thesolutionbecamewhiteandstickyatfirst(itwasstillacidic),thenitbecamewhitesolution,afterthatthesolutionbecameclear(itwasalkaline,pH=11).

Afterfiltratingoutthesubsidence,dilutehydrochloricacidwasadded.Inthefirstplace,somegrainlikesubsidenceshowedup,thenitbecameturbid.

0.9020gcrudeproductwasgainedafterfiltrationanddrying.

Assoonaspetroleumetherwasadded,whitesubsidenceappeared.

0.1103grefinedproductwasgainedafterfiltrationanddrying.

八.数据记录表格:

Theoxidationprocedure:

Theweightofcrudep-nitrobenzoicacid:

0.85g

Theweightofpurifiedp-nitrobenzoicacid:

0.73g

TLCanalyses:

Product(crude)p-nitrotolueneProduct(purfied)p-nitrotoluene

Rf=0.18Rf=0.87Rf=0.17Rf=0.89

m.p.determination(crudeproduct)

Tfirst

Ttot

ΔT

T

Taverage

1

234

239

5

236

237

2

235

4

m.p.determination(refinedproduct)

240

3

238

241

Thereductionprocedure:

Theweightofcrudep-aminobenzoicacid:

0.9020g

Theweightofrecrystallizedp-aminobenzoicacid:

0.1103g

九.产率计算:

Theyieldofp-nitrobenzoicacid:

0.73g÷

167.13g/mol÷

(2.5g÷

137.1378g/mol)×

100%=23.96%

Theyieldofp-aminobenzoicacid:

0.1103g÷

137.14g/mol÷

(0.73g÷

167.13g/mol)×

100%=18.41%

Totalyield:

23.96%×

18.41%=4.41%

十.实验讨论:

Theyieldwasrelativelylow,anddidnotreachthereportedyieldaccordingtothereferences.Thefollowingreasonsmaygivetheexplanations:

1.Because250mlthree-neckedflaskwasnotoffered,theamountofingredientcouldnotmatchwhathadbeenrequiredintheexperimentalscheme.Theamountofingredientwashalved,whichmeanttheregularlossintransferandotherexperimentaloperationsaccountedformoreproportion.

2.Intheoxidationprocedure,thetimeforrefluxwas60min,whichseemednotlongenoughforp-nitrotoluenetobecompletelyoxidized.

3.TherewasnoneedtodothepurificationinthesecondweeksinceTLCanalysisshowedtheproductdidnotcontaintheingredient--p-nitrotoluene.Andrecrystallizationinevitablyreducedtheyieldofp-nitrobenzoicacid.

4.Althoughpetroleumloweredp-aminobenzoicacid’ssolubilityinethanol,therestilldissolvedarelativelargeamountofproductinthesolvent.

5.ThepHwasnotsetwellwhencrudep-aminobenzo