NUMERICAL SIMULATION OF IMPACT ON CERAMIC ARMOUR SYSTEMWord文档格式.docx

《NUMERICAL SIMULATION OF IMPACT ON CERAMIC ARMOUR SYSTEMWord文档格式.docx》由会员分享,可在线阅读,更多相关《NUMERICAL SIMULATION OF IMPACT ON CERAMIC ARMOUR SYSTEMWord文档格式.docx(14页珍藏版)》请在冰豆网上搜索。

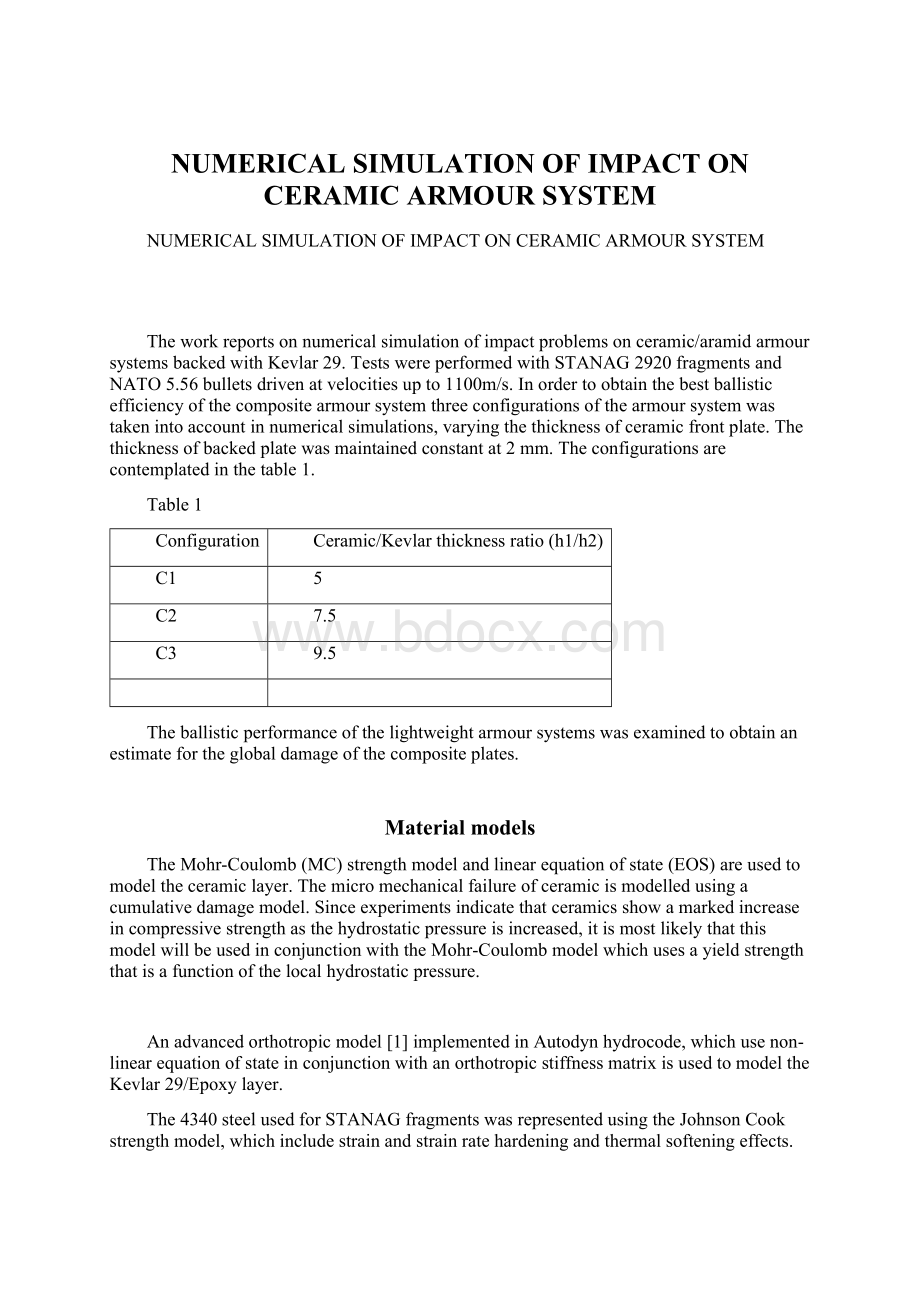

Theballisticperformanceofthelightweightarmoursystemswasexaminedtoobtainanestimatefortheglobaldamageofthecompositeplates.

Materialmodels

TheMohr-Coulomb(MC)strengthmodelandlinearequationofstate(EOS)areusedtomodeltheceramiclayer.Themicromechanicalfailureofceramicismodelledusingacumulativedamagemodel.Sinceexperimentsindicatethatceramicsshowamarkedincreaseincompressivestrengthasthehydrostaticpressureisincreased,itismostlikelythatthismodelwillbeusedinconjunctionwiththeMohr-Coulombmodelwhichusesayieldstrengththatisafunctionofthelocalhydrostaticpressure.

Anadvancedorthotropicmodel[1]implementedinAutodynhydrocode,whichusenon-linearequationofstateinconjunctionwithanorthotropicstiffnessmatrixisusedtomodeltheKevlar29/Epoxylayer.

The4340steelusedforSTANAGfragmentswasrepresentedusingtheJohnsonCookstrengthmodel,whichincludestrainandstrainratehardeningandthermalsofteningeffects.

AmodeloftheNATO5.56bulletwasdevelopedusingmaterialdataavailablefromexistingAutodynmodellibrariesandparametersmodifiedbaseduponthemeasuredhardnessofthebullet´

sindividualcomponents.Thebulletisofthree-partconstructionwithahardsteeltiparelativelysoftleadcoreandacooper-alloygildingjacket.Thereisasmallgapbetweenthefrontofthesteeltipandthegildingjacket.Thenominalmassofthebulletis4.0gandithasanaveragevelocityof1100m/swhenfiredfromastandardproofmountandwithastandardcartridgecase.

AshockequationofstateandJohnson-Cookconstitutivemodelwasusedtosimulatethematerialresponsetodynamicloadingofbullet´

stipwithyieldstressYS=1539MPa.ThecoppergildingmetalwasmodelledusingsimplelinearequationofstateandJohnson-Cookconstitutivemodel,thetieldstressYS=330.75MPa.TheleadcorewasmodelledusingasimplelinearequationofstateandaSteinberg-Guinanconstitutivemodel,theyieldstresswassetatYS=20MPa.Thefailureofjacketwassimulatedusingaprinciplestrainfailuremodelsetat90%.

Thematerialmodelsanddataaresummedupinthefollowingtable.

Table2Materialdata

Ceramic-Gceramic(Autodynmateriallibraries)

StrengthModel:

Mohr-Coulomb

Pressure#1(kPa)–5.00E5

Pressure#2(kPa)0.00

Pressure#3(kPa)1.01E20

Pressure#4(kPa)1.01E20

YieldStress#1(kPa)0.00

YieldStress#2(kPa)3.80E6

YieldStress#3(kPa)3.80E6

YieldStress#4(kPa)3.80E6

Failure:

CumulativeDamage

Eff.Pl.StrainatZeroDamage:

0.01

Eff.Pl.StrainatMax.Damage:

0.03

MaximumDamage:

0.7

Equationofstates

:

Linear

Referencedensity(g/cm3)

3.43

Bulkmodulus(kPa)1.54E8

Strength

Mohr-Coulomb

Shearmodulus(kPa)8.30E7

Failure

ReferenceTemperature(K)300

KEVLAR/EPOXY-EMI

TensilefailureStress11(kPa)

5.00E+04

MaximumShearStress12(kpa)

1.00E+05

TensileFailureStrain11

TensileFailureStrain22

0.20

TensileFailureStrain33

PostFailureResponse

Orthotropic

Fail11&

11Only

Fail22&

22Only

Fail33&

33Only

Fail12&

12and11Only

Fail23&

23and11Only

Fail31&

31and11Only

ResidualshearStiff.Frac.0.20

Orthotropic

Sub-EquationofStates

Polynomial

1.40

Youngmodulus11(kPa)

2.392E+05

Youngmodulus22(kPa)

6.311E+06

Youngmodulus33(kPa)

Poisonsratio12

0.115

Poisonsratio23

0.216

Poisonsratio31

3.034

Elastic

Shearmodulus(kPa)1.54E+06

MaterialStress/Strain

4340Steel

EquationofStates

Referencedensity(g/cm3)7.83

Bulkmodulus(kPa)1.59E+07

Referencetemperature(K)300

Specificheatcapacity(J/kgK)477

Johnson-Cook

Shearmodulus(kPa)8.18E+07

YieldStress(kPa)7.92E+05

Hardeningconstant(kPa)5.10E+05

Hardeningexponent0.34

Strainrateconstant0.014

Thermalsofetningexponent1.03

Meltingtemperature(K)1793

Failuremodel

None

Numericalmodels

Asthehighvelocityimpactphenomenonisoflocalisednature,theboundaryconditionsd