汪秘锅炉启动操作票.docx

《汪秘锅炉启动操作票.docx》由会员分享,可在线阅读,更多相关《汪秘锅炉启动操作票.docx(38页珍藏版)》请在冰豆网上搜索。

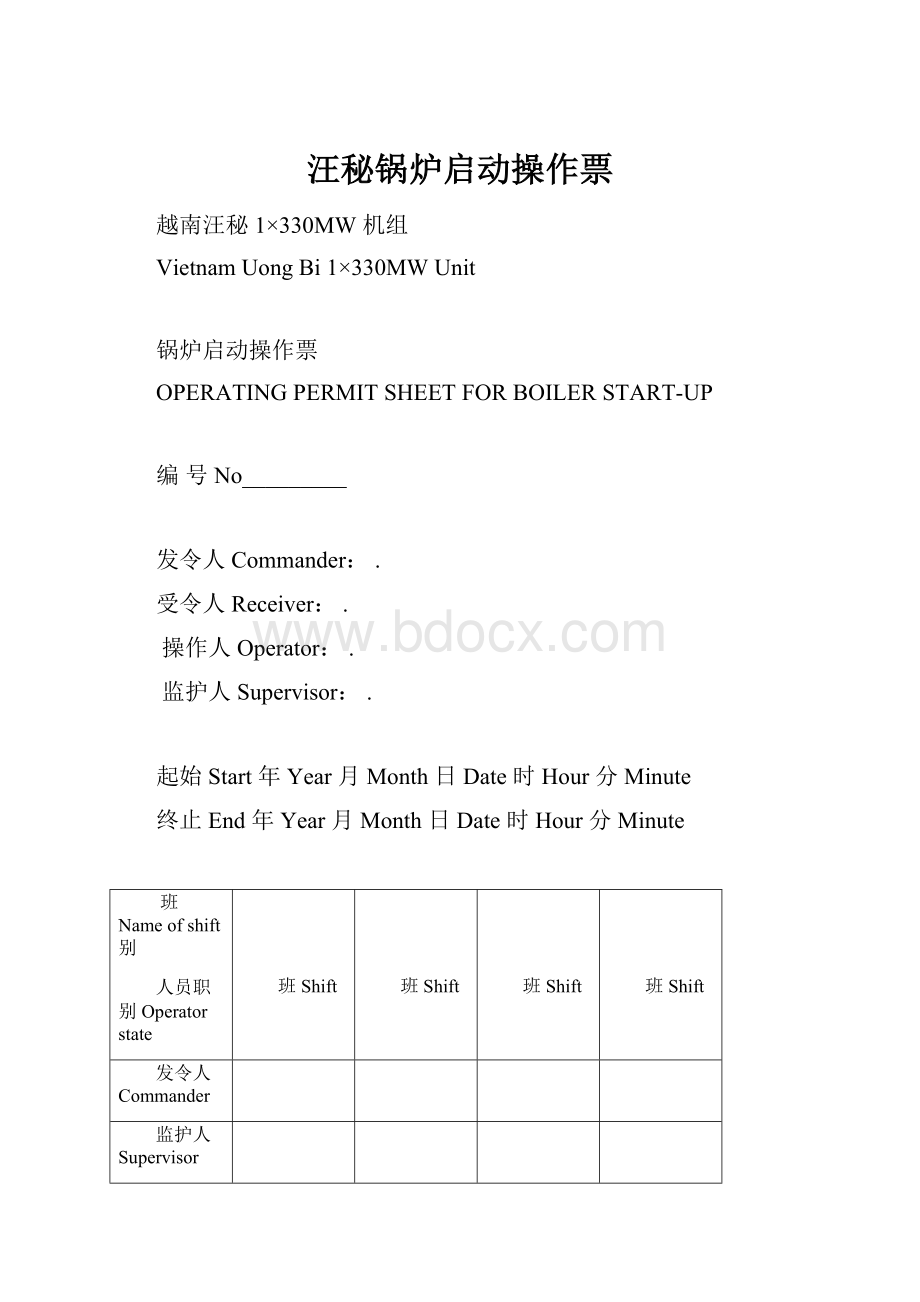

汪秘锅炉启动操作票

越南汪秘1×330MW机组

VietnamUongBi1×330MWUnit

锅炉启动操作票

OPERATINGPERMITSHEETFORBOILERSTART-UP

编号No_________

发令人Commander:

.

受令人Receiver:

.

操作人Operator:

.

监护人Supervisor:

.

起始Start年Year月Month日Date时Hour分Minute

终止End年Year月Month日Date时Hour分Minute

班Nameofshift别

人员职别Operatorstate

班Shift

班Shift

班Shift

班Shift

发令人Commander

监护人Supervisor

操作人Operator

交班

时间Handovertime

日

时

分Day

Hour

Minute

日

时

分

Day

Hour

Minute

日

时

分

Day

Hour

Minute

日

时

分

Day

Hour

Minute

操作票使用说明

Theapplicationnotesforthisoperationsheet

1

每项操作完毕,由监护人在“执行”栏上打“√”。

具体操作人则在“操作人”栏签名。

Aftertheoperationforeachitemisfinished,the“√”inthe“execution”blankshouldbetickedbythesupervisorandtheconcreteoperatorshouldsigninthe“operator”blank.

2

如遇到某项操作本次不需要操作时,由监护人在“执行”栏上打“—”记号。

Ifoneitemdoesnotneedtobeoperated,thesupervisorshouldtick“—”inthe“executionblank.

3

在操作过程中,遇到特殊情况及异常,则记录在备注栏内。

Duringtheoperation,ifthereisspecialconditionorabnormality,takedownontheremarkblank.

4

其它操作及注意事项按规程执行。

Otheroperationandnoticesshouldbeexecutedaccordingtothestipulations.

锅炉启动操作票

Boilerstartupoperationsheet

序号

No.

操作内容

Operationcontents

执行

时间

Executedtime

执行情况

Executingcondition

操作人

Operator

一、启动前的检查

A.Theinspectionbeforestartup

1

接值长指令后,受令人(班长)组织所属班员作好操作分工;准备好操作所需工器具。

Afterreceivingtheorderformtheshiftengineer,thereceiver(foreman)shouldorganizehisstaffstoassigntheworkandpreparealltheneededapparatusandtools.

2

检查所有检修工作全部结束,工作票已全部注销并收回,一切安全措施拆除,现场清理干净,设备管道保温完整,道路畅通,照明良好。

Checkalltheoverhaulhadbeenfinished,theworkingpermitsheethadbeencanceled,allthesafetymeasureshadbeendismantled,thesitehadbeenclear,theinsulationforthepipingiscompleted,theroadisnotimpededandthelightingisgood.

3

机组启动前的联锁保护试验按运行规程要求已完成,试验合格;

Beforethestartoftheunit,theprotectiontestfortheinterlockhadbeendoneaccordingtothemanualandthetestisqualified.

4

按规程要求检查系统、设备符合正常启动条件,相关阀门处于启动要求的开、关状态,相应联锁、保护处于投入位置。

Checkthesystemaccordingtothemanual,allthedevicesareinaccordancewiththenormalstartupcondition,therelativevalvesshouldbeatopenorclosepositionaccordingtherequirementofthestart,andthecorrespondinginterlockandprotectionareattheservicepositions.

5

投入闭式水系统,检查确认各转机冷却水系统运行正常;

Puttheclosedcircuitwatersystemintoservice,checkeachcoolingsystemofeachrotarymachineworksnormally.

6

投入空压机系统,确认系统运行正常。

Putthecompressorsystemintoserviceandconfirmthesystemworksnormally.

7

点火前3小时启动轻油、重油(加热条件具备)供油泵,炉前油系统打循环。

3hoursbeforetheignition,startthelightandheavyoilforwardingpumpsincludingtheheatingdevicesandmaketheoilcirculateatthefrontoftheboiler.

8

锅炉点火前12小时投入电除尘器阴极瓷套保温箱及阴极振打瓷轴保温箱加热装置,投入灰斗电加热。

12hoursbeforetheignition,puttheheatersforthenegativepoleporcelainsleevethermostatboxofelectricde-dusterandthenegativepolevibrationporcelainshaftthermostatboxandtheheaterfortheashbucketintooperation.

9

启动润滑油泵、调节油泵运行,投入润滑油系统。

并检查确认各润滑油系统运行正常。

Startthelubeoilpumpandtheregulationoilpumpandputthelubeoilsystemintooperation,andcheckandconfirmwhethereachlubeoilsystemworksnormallyornot.

10

开启汽包及各过热器空气门,关闭给水管道疏水门。

联系汽机启动给水泵向锅炉上水至正常水位。

Opentheventvalvesofdrumandeachsuperheater,closethedrainvalvesoffeedwaterpumping,informtheturbineoperatortostartthefeedwaterpumptofeedwatertotheboilertilltothenormalwaterlevel.

11

锅炉上水期间应控制汽包壁温差≯50℃,记录各部膨胀指示。

上水完毕后校对各水位计。

Duringthefeeding,controlthewalltemperatureofthedrumwithin≯50℃andrecordtheexpansionindicationofeachpart.Aftertheendofwaterfeeding,calibrateeachwatergauge.

12

点火前4至6小时投入辅助蒸汽系统,正常后投入炉底蒸汽加热,记录加热前和加热后各部膨胀指示。

4-6hoursbeforeignition,puttheauxiliarysteamsystemintooperation,afteritisnormal.Heattheboilerbottomwithsteam,recordtheexpansionindicationateachpartbeforeandaftertheheating.

13

确认炉底密封完好。

Confirmthesealingoftheboilerbottomisgood.

14

锅炉点火前2小时投入电除尘器各振打装置。

2hoursbeforeignition,putthevibratoroftheelectricde-dusterintoservice.

15

汽包水温100℃,解列炉底蒸汽加热,通知汽机。

Whenthedrumwatertemperatureis100℃,stoptheheatingfortheboilerbottomandtheninformtheturbineoperator.

16

蒸汽加热完毕后,放水至汽包正常水位,投入省煤器再循环。

Aftertheheatingisend,dischargewatertothenormalwaterlevelofdrumandputtherecirculationofeconomizerintoservice.

二、启动操作步骤

B.Startoperationsteps

17

联系值长、电气,启动风烟系统,确认空预器启动条件满足,启动A、B空预器运行;

Informshiftengineerandelectricshiftoperator,starttheairandfluegassystems,confirmtheconditiontostarttheairpreheatedisokandstarttheA、Bairpreheaters.

18

检查引、送风机启动条件满足,联系值长、电气,依次启动引风机、送风机运行,调整炉膛总风量在30%~40%之间,调节炉膛负压正常。

ChecktheconditionsforstartingtheIDandFDfansaresatisfied,informtheshiftengineerandtheelectricoperator,starttheIDandFDfansinturns,adjustthetotalairquantityofthefurnacebetween30%~40%andregulatethenegativepressureofthefurnacetobenormal.

19

投入炉膛负压自动控制。

Puttheautocontrolofthefurnacenegativepressureintoservice.

20

启动火焰检测冷却风机运行,运行正常后投入联锁,

Startthecoolingfanoftheflamedetectorintooperation,afteritisnormal,puttheinterlockintoservice.

21

检查各煤、油火焰检测器冷却风门开启,且风压大于5Kpa,投入炉膛烟温探针。

Checktheairvalvesofeachcoalandoilflamedetectorareopenedandtheairpressureismorethan5Kpaandputthefluegasprobeoffurnaceintooperation.

22

联系值长、汽机,确认点火条件具备,检查确认炉膛吹扫条件满足,按下“炉膛吹扫”按钮,5分钟后吹扫完成。

Informtheshiftengineerandturbineoperator,confirmtheignitionconditionisready,checkandconfirmthepurgeconditionoffurnaceissatisfied,pushdownthe“furnacepurge”button,after5minutes,thepurgeiscompleted.

23

锅炉点火:

投入油枪,对角投入油枪使炉膛均匀受热;调整相应的风门挡板开度,保证燃烧正常;

Ignitetheboiler,putthe---oilgunintoservice,puttheoilgunintoserviceonthecrossformakingthefurnaceheatingevenly,adjusttherelativeopeningoftheairdamperforensuringthecombustionnormally.

24

锅炉点火起压后机组按启动升温升压曲线以及金属温升率,控制升温、升压速度。

Aftertheignitionandpressurizing,controlthetemperatureandpressurerisingspeedaccordingtothetemperatureandpressurerisingcurveandthemetaltemperaturerisingratio.

25

用锅炉启动对空排汽阀的开度配合控制锅炉升温升压速度。

Controltheboilertemperatureandpressurerisingspeedincoordinatewiththeopeningofthevalvetoatmosphere.

26

主汽压力在0.15~0.2MPa时,联系汽机投入旁路系统,再热器通汽保护,同时关闭汽包及过热器空气门,开启过热器疏水门,如连续向汽包供水,关闭省煤器再循环。

Whenthemainsteampressureisat0.15~0.2Mpa,informtheturbineoperatortoputthebypasssystemandthesteamcirculationprotectionofthereheaterintooperation,atsametime,closetheventvalvesofthedrumandthesuperheater,openthedrainvalveofthesuperheater,ifthewateriscontinuouslyfedtothedrum,closetherecirculationofeconomizer.

27

主汽压力升至0.4MPa时冲洗水位计,通知相关人员冲洗压力表管、冲洗水位变送器,并校对水位;通知相关人员热紧螺丝。

Whenmainsteampressurerisesto0.4Mpa,flushthewaterlevelgauge,informtheoperatorconcernedtoflushthepressuregaugepipeandthetransmitterofwaterlevel,calibratethewaterlevelandinformtherelativestafftotightenthescrewsinhotcondition.

28

压力0.5MPa时,定排一次。

Whenpressureis0.5Mpa,oncecarryouttheperiodicblowdown.

28

锅炉点火后可根据饱和蒸汽温升情况逐步成对角增加油枪;确保汽包最大壁温差小于50℃。

Aftertheignitionofboiler,theoilgunscanbeincreaseonthecrossstepbystepaccordingtothesaturatedsteamtemperaturerisingforensuringthemax.walltemperaturedifferenceofdrumislessthan50℃.

29

汽包压力达1.5MPa时,投入锅炉连续排污。

Whenthedrumpressureisupto1.5Mpa,doboilercontinuousblowdown.

30

根据升温升压曲线控制压力及汽温,并对锅炉进行全面检查,炉膛出口烟温达到538℃时退出炉膛烟温探针,

Controlthepressureandtemperatureofsteamaccordingtothetemperatureandpressurerisingcurveandthoroughlychecktheboiler,withdrawthefluegasprobeoffurnacewhentheoutletfluegastemperatureofboilerfurnaceisupto538℃.

31

冲转条件满足后汇报值长,做好冲转前的准备,接冲转命令后全面检查机组正常,冲转前的蒸汽参数:

主蒸汽压力4.0MPa、温度380℃;再热蒸汽温度350℃,再热主蒸汽压力,1.0MPa、。

Aftertheinitiatingconditionissatisfied,reporttotheshiftengineer,preparetoinitiate.Afterreceivingtheinitiationorder,thoroughlychecktheunitwhichshouldbenormal.Theparametersbeforetheinitiation:

themainsteampressureis4.0Mpa,temperatureis380℃;thereheatsteamtemperatureis350℃;thepressureis1.0Mpa.

32

汽机冲转后关闭未级过热器排汽门,可根据参数逐步关闭各级过热器疏水门,维持汽温汽压稳定。

Aftertheinitiationofturbine,closetheexhauststeamvalveofthelaststagesuperheater,accordingtotheparameter,stepbystepclosethedrainvalvesateachstageofsuperheaterandmaintainthesteamtemperatureandpressurestable.

33

负荷15%B-MCR时,根据系统情况,辅助蒸汽联箱汽源切换为冷段再热器管道供给。

Whentheloadis15%B-MCRandaccordingtothesystemcondition,changeoverthesteamfromtheauxiliarysteamheaddertothesteamofthereheaterpipingatcoldsection.

34

机组并网后根据升温升压曲线增投油枪升温升压,升至20~30%额定负荷时给水由旁路切至主路运行,汽包水位由电泵转速自动控制。

Aftertheunitissynchronized,increasetheoilgunstorisethetemperatureandpressureaccordingtothetemperatureandpressurerisingcurve,aftertheloadisincreasedtoabout20-30%ofratedload,thewaterwillbefedfrombypasstothemainpipingandthewaterlevelofthedrumwillbecontrolledbythemotorizedpumpautomatically.

35

汽包压力>5MPa,热风温度>250℃根据升负荷情况可启,投运煤粉燃烧器。

Whenthedrumpressureis>5MPa,thehotairtemperatureis>250℃,accordingtotheloadrisingcondition,thecoalburnercanbeputintooperation.

36

主汽压力10MPa时,加大锅炉连续排污,锅炉洗硅,联系值长通知化学检查炉水含硅量,合格后再继续升负荷。

Whenthema